4 - 1

4. INSPECTION

4. INSPECTION

WARNING

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Then, confirm that the voltage

between P and N is safe with a voltage tester and others. Otherwise, an electric

shock may occur. In addition, always confirm from the front of the servo amplifier

whether the charge lamp is off or not.

Any person who is involved in inspection should be fully competent to do the work.

Otherwise, you may get an electric shock. For repair and parts replacement,

contact your safes representative.

POINT

Do not disassemble and/or repair the equipment on customer side.

(1) Inspection

It is recommended to make the following checks periodically.

(a) Check the servo motor bearings, brake section, etc. for unusual noise.

(b) Check the cables and the like for scratches and cracks. Especially when the junction cable is

movable, perform periodic inspection according to operating conditions.

(c) Check the servo motor shaft and coupling for misalignment.

(d) Check the power supply connector and encoder connector tightening screws for looseness.

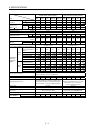

(2) Life

The following parts must be changed periodically as listed below. If any part is found faulty, it must be

changed immediately even when it has not yet reached the end of its life, which depends on the

operating method and environmental conditions. For parts replacement, please contact your sales

representative.

Part Name Guideline of Life Remarks

Bearings 20,000 to 30,000 hours

Encoder 20,000 to 30,000 hours

Oil seal 5,000 hours

Cooling fan 20,000 hours

The Guideline of Life field gives the reference time. If any fault

is found before this time is reached, the part must be changed.

(a) Bearings

When the servo motor is run at rated speed under rated load, change the bearings in 20,000 to

30,000 hours as a guideline. This differs on the operating conditions. The bearings must also be

changed if unusual noise or vibration is found during inspection.

(b) Oil seal

Must be changed in 5,000 hours of operation at rated speed as a guideline. These parts must also

be changed if oil leakage, etc. is found during inspection.