8 - 5

8. CALCULATION METHODS FOR DESIGNING

8.5 Capacity selection

As a first step, confirm the load conditions and temporarily select the servo motor capacity. Then,

determine the operation pattern, calculate required torques according to the following equations, and

check that the servo motor of the initially selected capacity may be used for operation .

(1) Initial selection of servo motor capacity

After calculating the load torque (T

L) and load inertia moment (JL), select a servo motor which will

satisfy the following two relationships:

Servo motor's rated torque

TL

Servo motor JM JL/m

m

3 : High duty (more than 100 times/min.)

Settling time 40ms or less

m

5 : Middle duty (60 to 100 times/min.)

Settling time 100ms or less

m

permissible load inertia moment : Low duty (less than 60 times/min.)

Settling time more than 100ms

Find the acceleration and deceleration torques and continuous effective load torque as described in (2)

to make a final selection. For high-duty positioning, the load inertia moment (J

L) value should be as

small as possible. If positioning is infrequent as in line control, the load inertia moment (J

L) value may

be slightly larger than in the above conditions.

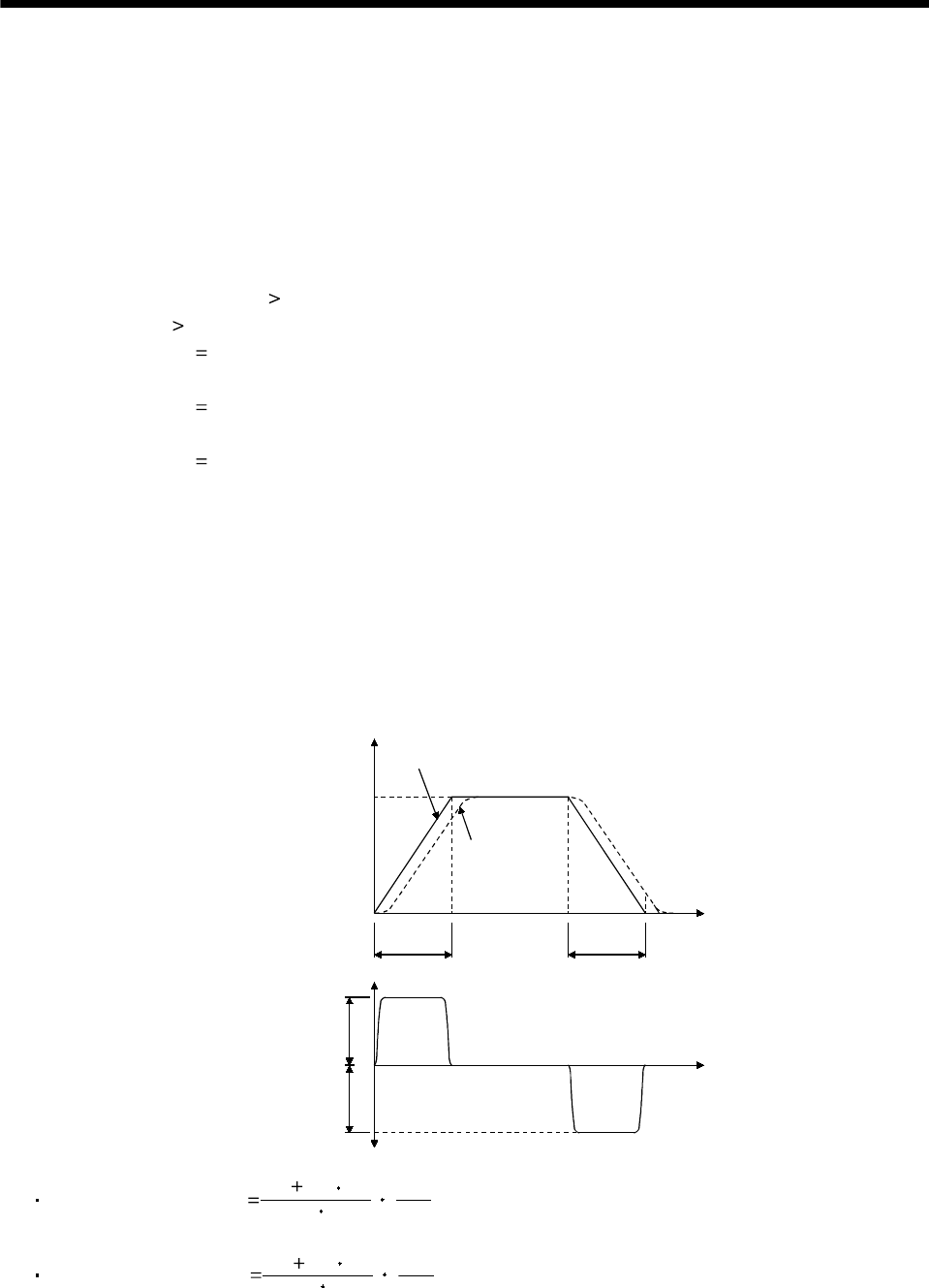

(2) Acceleration and deceleration torques

The following equations are used to calculate the acceleration and deceleration torques in the

following operation pattern:

C

o

m

m

a

n

d

p

u

l

s

e

S

e

r

v

o

m

o

t

o

r

s

p

e

e

d

[

r

/

m

i

n

]

0

0

Nofo

Time

Time

Command

Servo motor

speed

t

psa

T

a

T

d

Deceleration

torque

A

cceleration

torque

f

r

e

q

u

e

n

c

y

f

[

p

p

s

]

t

psd

Acceleration torque Ta

9.55 10

4

(J

L

J

M

) No

tpsa

1

........................................................................................(8.9)

Deceleration torque Td

9.55 10

4

(JL JM) No

tpsd

1

.....................................................................................(8.10)