8 - 11

8. CALCULATION METHODS FOR DESIGNING

(2) Set the end (OFF position) of the actuator signal at the middle of two ON positions (Lows) of the zero

pulse signal. If it is set near either ON position of the zero pulse signal, the positioning unit is liable to

misdetect the zero pulse signal. In this case, a fault will occur, e.g. the home position will shift by one

revolution of the servo motor.

The zero pulse output position can be confirmed by OP (encoder Z-phase pulse) on the external I/O

signal display.

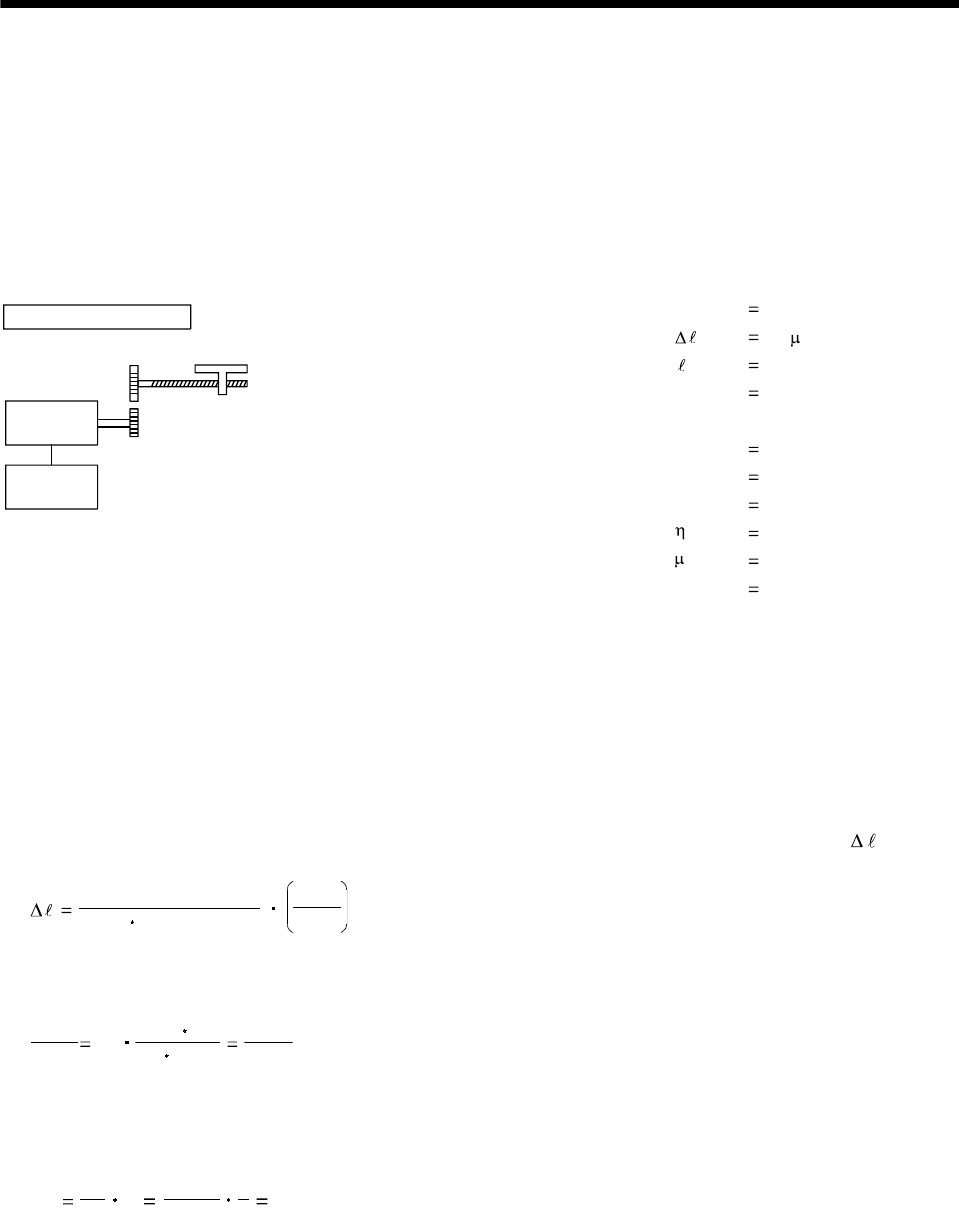

8.10 Selection example

Speed of moving part during fast feed V0 30000[mm/min]

Command resolution 10[ m]

Travel 400[mm]

Positioning time t

0 within 1[s]

Number of feeds 40[times/min]

Operation cycle tf

1.5[s]

Gear ratio n

8/5

Moving part mass W

60[kg]

Drive system efficiency 0.8

Friction coefficient

0.2

Ball screw lead Pb 16[mm]

Ball screw diameter 20[mm]

Ball screw length 500[mm]

Gear diameter (servo motor) 25[mm]

Gear diameter (load shaft) 40[mm]

Machine specifications

Servo

motor

Servo

amplifier

Gear ratio 5:8

Gear face width 10[mm]

(1) Selection of control parameters

Setting of electronic gear (command pulse multiplication numerator, denominator)

There is the following relationship between the multiplication setting and travel per pulse

.

8192 (gear ration)

(ball screw lead)

CDV

CMX

When the above machining specifications are substituted in the above equation:

CDV

CMX

10

16 1000

8192 8/5

1000

8192

Acceptable as CMX/CDV is within 1/20 to 20.

(2) Servo motor speed

No

Pb

V

0

n

16

30000

5

8

3000[r/min]