2 - 5

2. INSTALLATION

2.4 Permissible load for the shaft

POINT

Do not use a rigid coupling as it may apply excessive bending load to the

shaft, leading to shaft breakage.

(1) Use a flexible coupling and make sure that the misalignment of the shaft is less than the permissible

radial load.

(2) When using a pulley, sprocket or timing belt, select a diameter that will fit into the permissible radial

load.

(3) Excess of the permissible load can cause the bearing life to reduce and the shaft to break.

(4) The load indicated in this section is static load in a single direction and does not include eccentric load.

Make eccentric load as small as possible. Not doing so can cause the servo motor to be damaged.

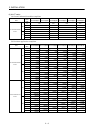

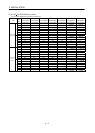

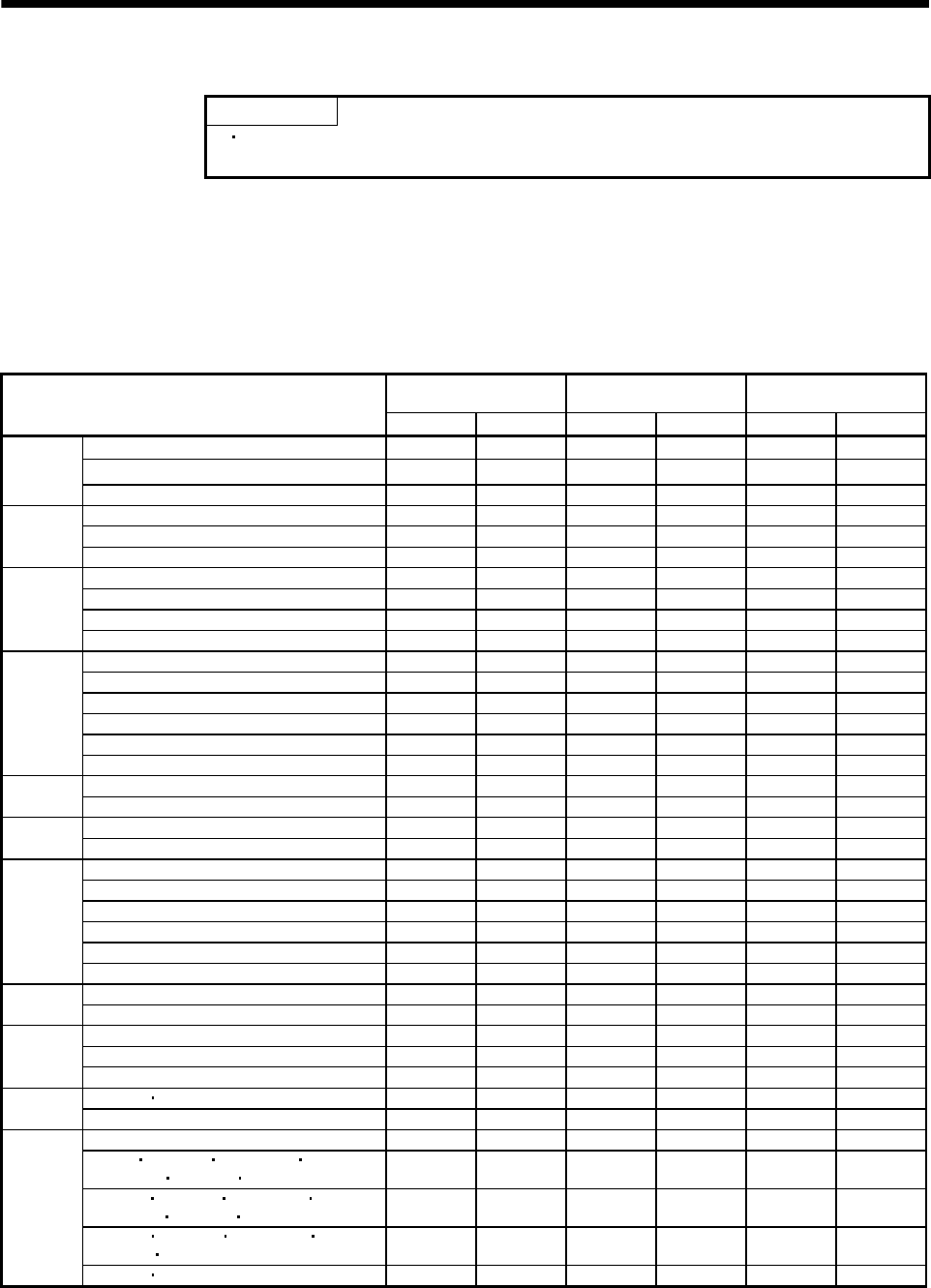

2.4.1 Without reduction gear

L (Note 1)

Permissible Radial Load

(Note 2)

Permissible Thrust Load

(Note 2)

Servo Motor

[mm] [in] [N] [lb] [N] [lb]

053 / 13 25 0.98 88 20 59 13

23 / 43 30 1.18 245 55 98 22

HC-KF

HC-KFS

73 (Note 3) 40 1.57 392 88 147 33

053 / 13 25 0.98 88 20 59 13

23 / 43 30 1.18 245 55 98 22

HC-MF

HC-MFS

73 40 1.57 392 88 147 33

053 30 1.18 108 24 98 22

13 30 1.18 118 27 98 22

23 / 33 30 1.18 176 40 147 33

HA-FF

43 / 63 40 1.57 323 73 284 64

81 55 2.17 980 220 490 110

121 to 301 79 3.11 2058 463 980 220

52 (4) to 152 (4) (Note4) 55 2.17 980 220 490 110

202 (4) / 702 (4) (Note4) 79 3.11 2058 463 980 220

53 to 153 55 2.17 980 220 490 110

HC-SF

HC-SFS

203 / 353 79 3.11 2058 463 980 220

52 to 152 55 2.17 980 220 490 110

HC-LFS

202/302 79 3.11 2058 463 980 220

103 to 203 45 1.77 686 154 196 44

HC-RF

HC-RFS

353 / 503 63 2.48 980 220 392 88

72 / 152 55 2.17 637 143 490 110

202 65 2.56 882 198 784 176

352 / 502 65 2.56 1176 264 784 176

13 25 0.98 88 20 59 13

23 / 43 30 1.18 245 55 98 22

HC-UF

HC-UFS

73 40 1.57 392 88 147 33

11K2 85 3.35 2450 551 980 220

HA-LH

15K2 / 22K2 110 4.33 2940 661 980 220

0135 16 0.63 34 8 14 3

0235 16 0.63 44 10 14 3HC-AQ

0335 16 0.63 49 11 14 3

30K2(4) 37K2(4) 140 5.51 3234 727 1470 330

HA-LF

45K24 /55K24 140 5.51 4900 1102 1960 441

502/702/601(4)/701M(4)/11K2(4) 85 3.35 2450 551 980 153

801(4) 12K1(4) 11K1M(4)

15K1M(4) 15K2(4) 22K2(4)

110 4.33 2940 661 980 153

15K1(4) 20K1(4) 22K1M(4)

30K1M(4) 30K2(4) 37K2(4)

140 5.51 3234 727 1470 330

25K1(4) 30K1(4) 37K1M(4)

45K1M4 45K24•55K24

140 5.51 4900 1102 1960 441

HA-LFS

37K1(4)

50K1M4 170 6.69 6370 1432 1960 441