2 - 4

2. INSTALLATION

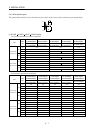

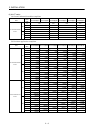

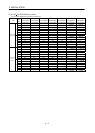

2.2 Installation orientation

The following table lists directions of installation.

Servo Motor Series Direction of Installation Remarks

HC-KF

HA-FF

HC-RF

HC-KFS

HC-SFS

HC-UFS

HC-MF

HC-SF

HC-UF

HC-MFS

HC-RFS

HC-LFS

HC-AQ

For installation in the horizontal direction, it is recommended to set the

connector section downward.

HA-LH

HA-LFS (Flange type)

May be installed in any

direction.

HA-LF

HA-LFS (Flange

leg type)

Horizontal direction with

the legs downward.

Use either the legs or flange for installation.

When the servo motor with electromagnetic brake is installed with the shaft end at top, the brake plate

may generate sliding sound but it is not a fault. Refer to section 5.3 for the installation orientation of the

servo motor with reduction gear.

2.3 Load remove precautions

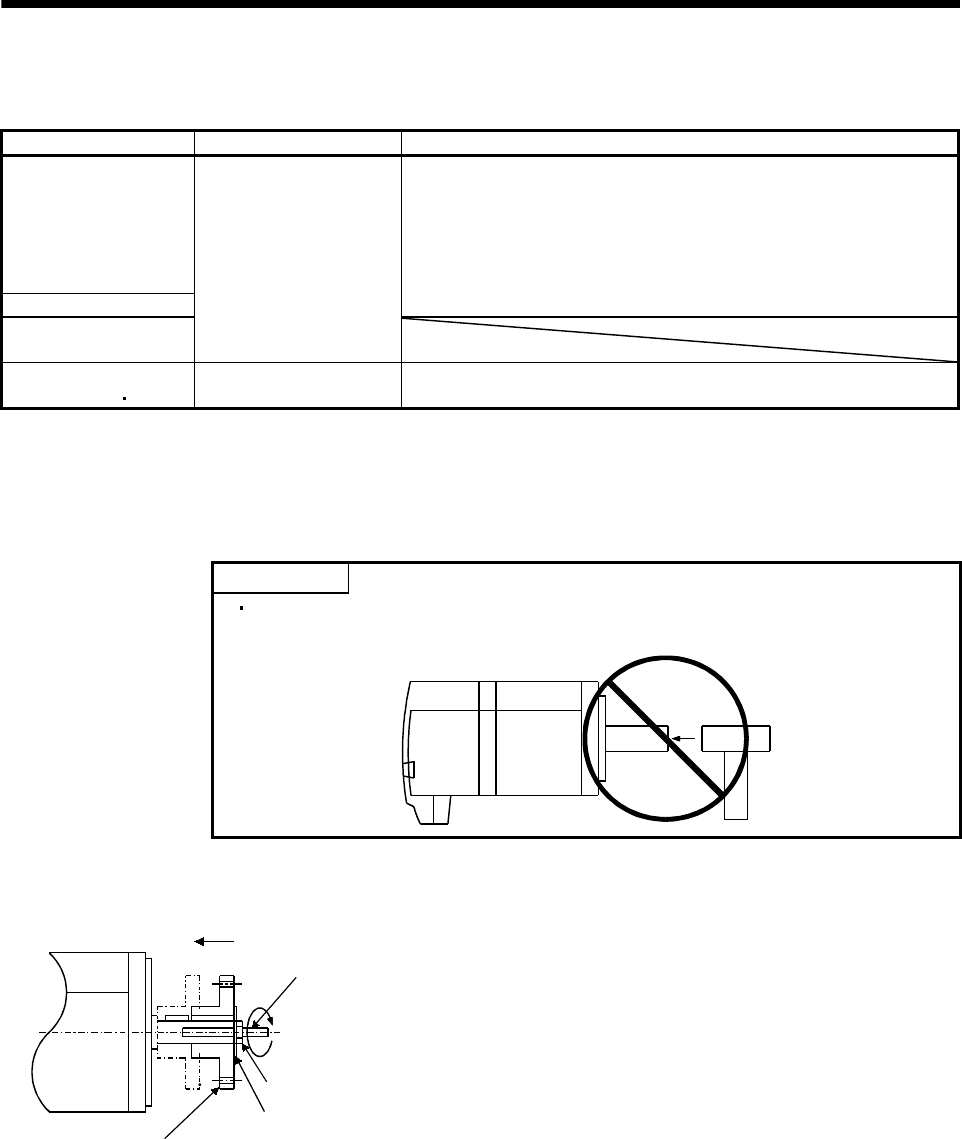

POINT

During assembling, the shaft end must not be hammered. Doing so can

cause the encoder to fail.

(1) When mounting a pulley to the servo motor shaft provided with a keyway, use the screw hole in the

shaft end. To fit the pulley, first insert a double-end stud into the screw hole of the shaft, put a washer

against the end face of the coupling, and insert and tighten a nut to force the pulley in.

Servo motor

Double-end stud

Nut

Washer

Pulley

(2) For the servo motor shaft with a keyway, use the screw hole in the shaft end. For the shaft without a

keyway, use a friction coupling or the like.

(3) When removing the pulley, use a pulley remover to protect the shaft from impact.

(4) To ensure safety, fit a protective cover or the like on the rotary area, such as the pulley, mounted to

the shaft.

(5) When a threaded shaft end part is needed to mount a pulley on the shaft, please contact us.

(6) The orientation of the encoder on the servo motor cannot be changed.

(7) For installation of the servo motor, use spring washers, etc. and fully tighten the bolts so that they do

not become loose due to vibration.

(8) For the HC-AQ series, use spring washers and apply Screw Lock to mount the servo motor. In

addition, use Helisert screws when the flange for mouthing the servo motor is made of aluminum.