APP - 28

A

PPENDICES

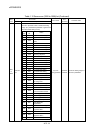

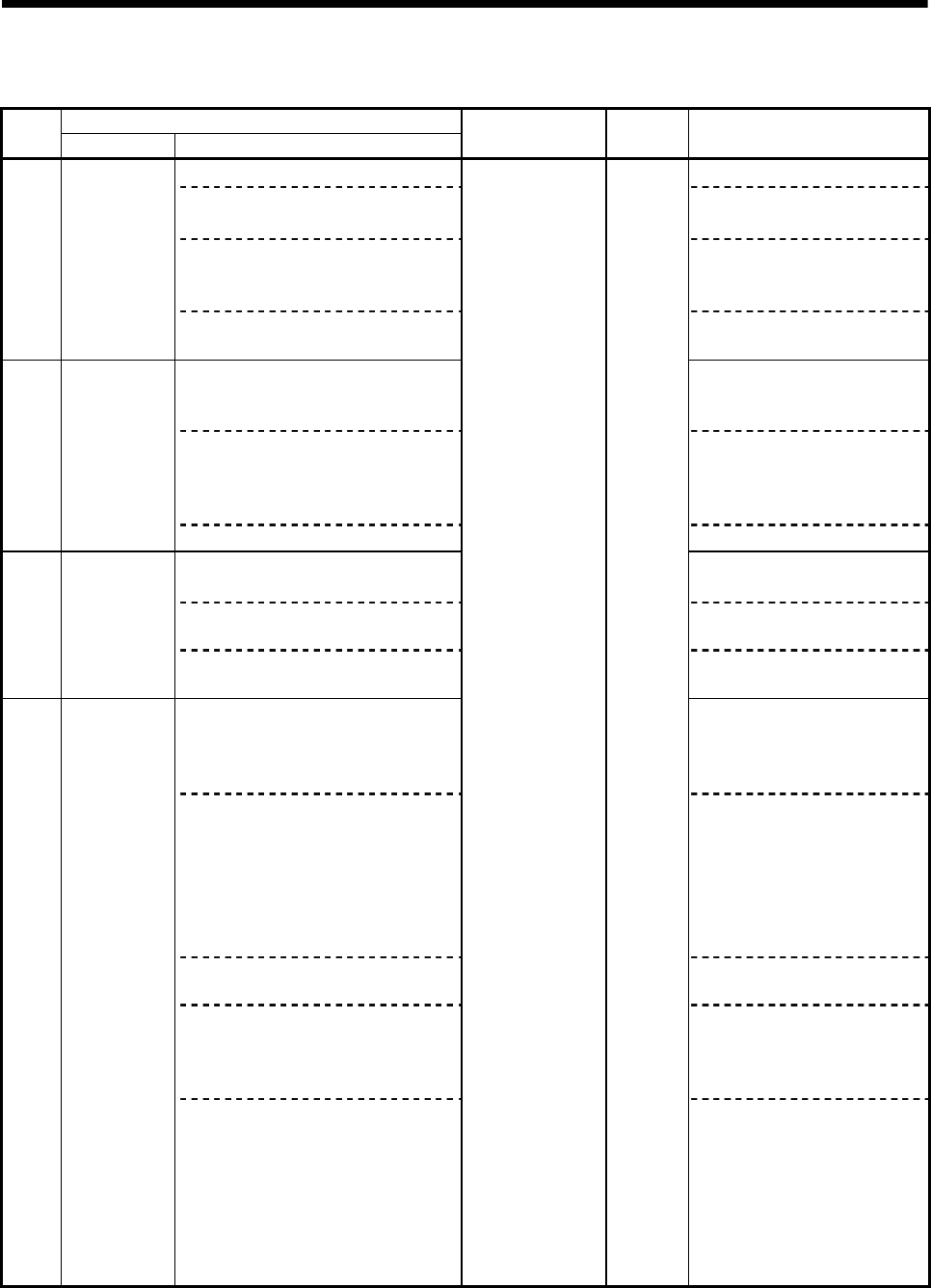

Table 1.12 Servo error (2000 to 2899) list (Continued)

Error cause Error

code

Name Description

Error check

Error

processing

Corrective action

• Servo amplifier failure • Replace the servo amplifier.

• The power supply was turned on and off

continuously by overloaded status.

• The drive method is reviewed.

• Ambient temperature of servo amplifier

is over 55[°C] (131[°F]).

• Review environment so that

ambient temperature is 0 to

55[°C] (32 to 131[°F]).

2045

Main circuit

device overheat

• Used beyond the specifications of close

mounting of servo amplifier.

• Use within the range of

specifications.

• Ambient temperature of servomotor is

over 40[°C] (104[°F]).

• Review environment so that

ambient temperature is 0 to

40[°C] (32 to 104[°F]).

• Servomotor is overloaded. • Reduce load.

• Review operation pattern.

• Use servomotor that provides

larger output.

2046

Servomotor

overheat

• Thermal sensor in encoder is faulty. • Replace the servomotor.

• Cooling fan life expiration • Replace the cooling fan of the

servo amplifier.

• Foreign matter caught in the fan stopped

rotation.

• Remove the foreign matter.

2047

Cooling fan

alarm

• The power supply of the cooling fan

failed.

• Replace the servo amplifier.

• Servo amplifier is used in excess

of its continuous output current.

• Reduce load.

• Review operation pattern.

• Use servomotor that provides

larger output.

• Servo system is instable and hunting. • Repeat acceleration/

deceleration to execute auto

tuning.

• Change auto tuning response

setting.

• Set auto tuning to OFF and make

gain adjustment manually.

• Machine struck something. • Review operation pattern.

• Install limit switches.

• Wrong connection of servo motor.

(Servo amplifier's output terminals U, V,

W do not match servo motor's input

terminals U, V, W.)

• Connect correctly.

2050 Overload 1

• Encoder faulty.

[Checking method]

When the servomotor shaft is rotated

with the servo off, the cumulative

feedback pulses do not vary in

proportion to the rotary angle of the shaft

but the indication skips or returns

midway.

Any time during

operation

Immediate

stop

• Replace the servomotor.