APP - 8

A

PPENDICES

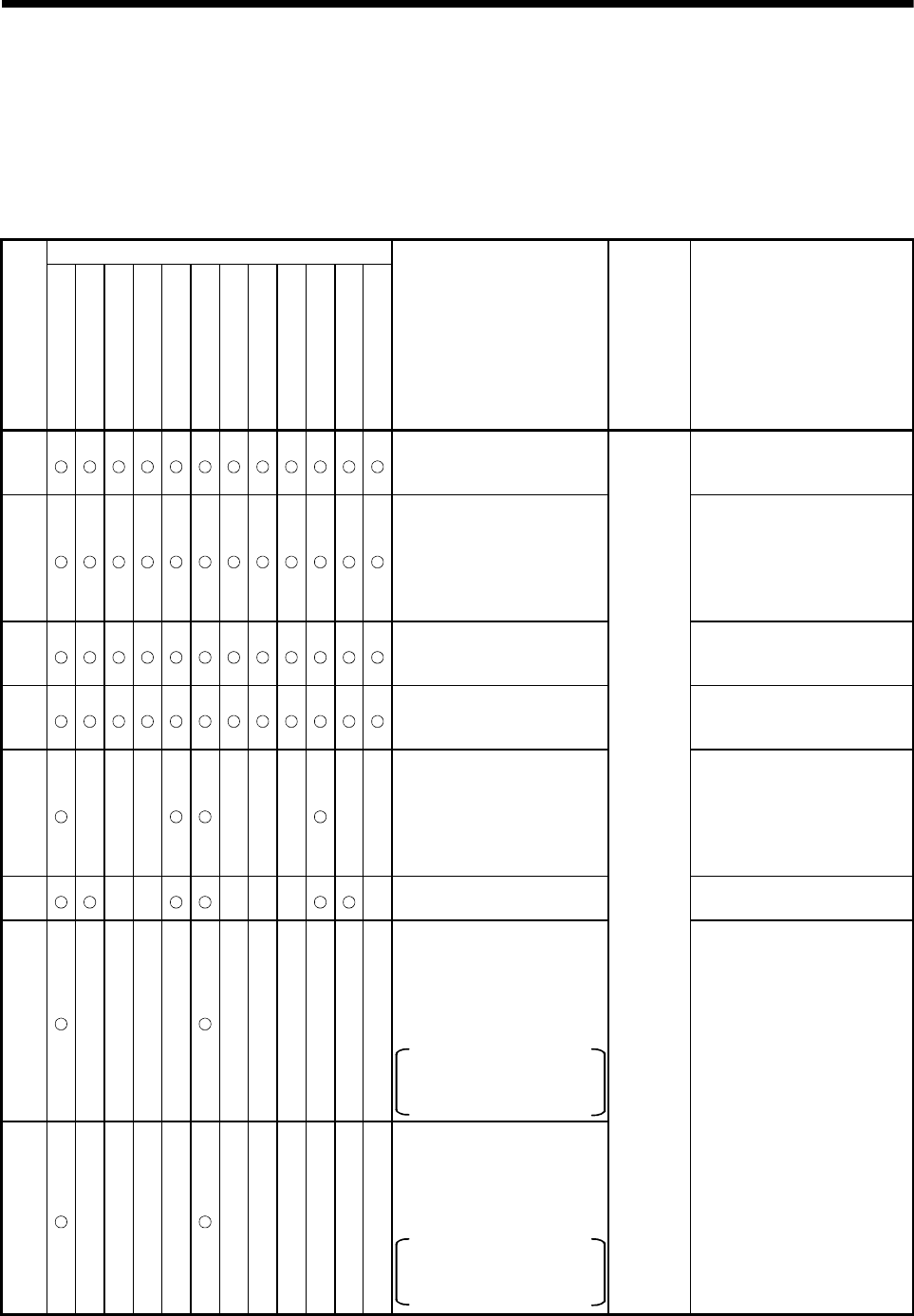

(2) Positioning control start errors (100 to 199)

These errors are detected at the positioning control start.

The error codes, causes, processing, and corrective actions are shown in Table

1.4.

Table 1.4 Positioning control start error (100 to 199) list

Control mode

Error

code

Positioning

Fixed-pitch feed

Speed

Speed/position switching

Speed switching

Constant-speed

JOG

Manual pulse generator

Home position return

Position follow-up control

OSC

Speed control with

fixed position stop

Error cause

Error

processing

Corrective action

100

• The PLC ready flag (M2000)

or PCPU ready flag (M9074)

is OFF.

• Set the Motion CPU to RUN.

• Turn the PLC ready flag

(M2000) on.

101

• The start accept flag (M2001

to M2032) for applicable axis

is ON.

• Take an interlock in the

program not to start the

starting axis. (Use the start

accept flag OFF of the

applicable axis as the starting

condition).

103

• The stop command

(M3200+20n) for applicable

axis is ON.

• Turn the stop command

(M3200+20n) off and start.

104

• The rapid stop command

(M3201+20n) for applicable

axis is ON.

• Turn the rapid stop command

(M3201+20n) off and start.

105

(Note)

• The feed current value is

outside the range of stroke

limit at the start.

• Set within the stroke limit

range by the JOG operation.

• Set within the stroke limit

range by the home position

return or current value

change.

106

(Note)

• Positioning is outside the

range of stroke limit.

• Perform the positioning within

the range of stroke limit.

• The address that does not

generate an arc is set at the

auxiliary point-specified

circular interpolation or

auxiliary point-specified

helical interpolation.

107

Relationship between the

start point, auxiliary point

and end point.

• The address that does not

generate an arc is set at the

R (radius) specified circular

interpolation R (radius)

specified helical interpolation.

108

(Note)

Relationship between the

start point, radius and

end point.

Positioning

control

does not

start.

• Correct the addresses of the

servo program.

(Note): These errors are stored the error codes of the all applicable interpolation axes at the interpolation operation.