6 - 71

6 POSITIONING CONTROL

ABH

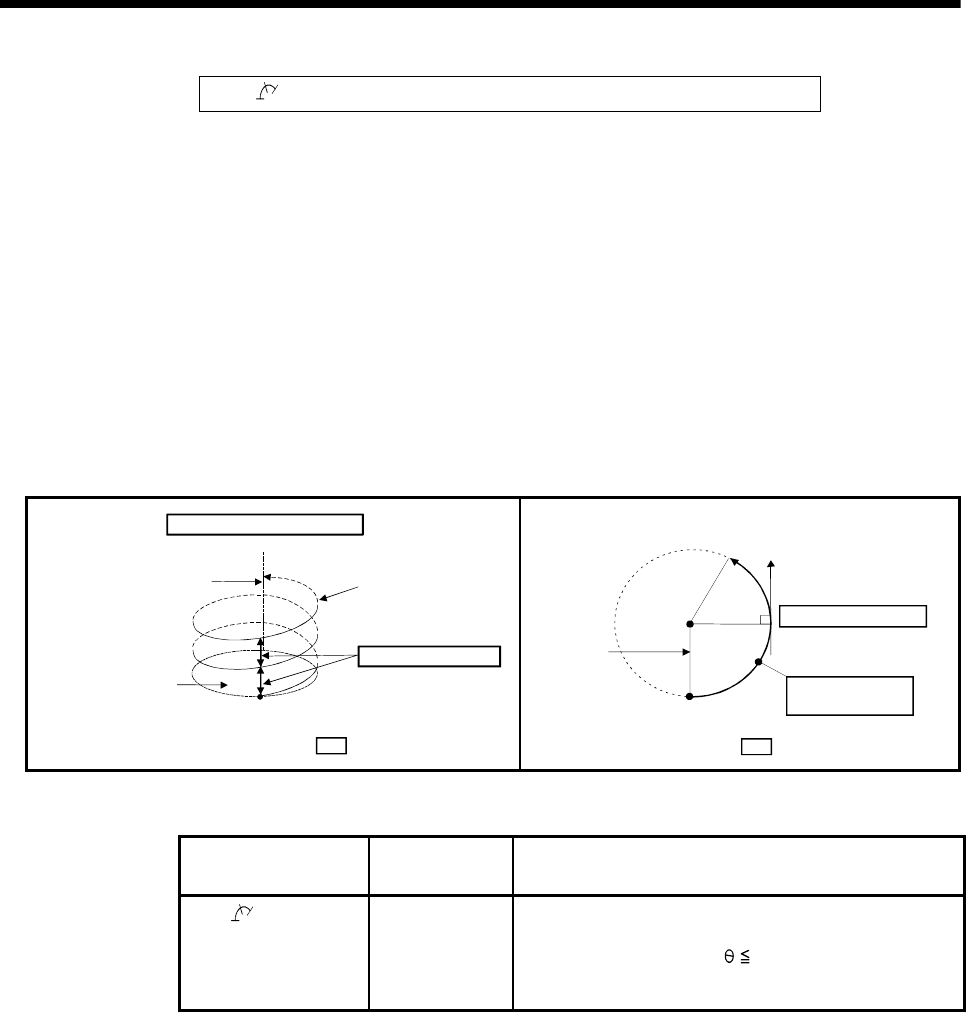

Absolute auxiliary point-specified helical interpolation control

[Control details]

The linear interpolation to other linear axis is executed performing 2 axes circular

interpolation from current stop position (X0, Y0, Z0) to specified circular end address

(X1, Y1) or linear axis end point address (Z1), and the absolute helical interpolation is

executed so that it may become a spiral course.

It goes around on the specified circle for the specified number of pitches, the circular

interpolation which had remainder specified is executed, and positioning to end

address is executed. The auxiliary point-specified circle specifies circular interpolation

method connected start point and end point at the seeing on the plane for which

performs circular interpolation.

Operation details for absolute auxiliary point-specified helical interpolation are shown

below.

Number of pitches a

End point address (X

,

Y

,

Z )

Start point (X

0,

Y

0,

Z

0

)

Helical interpolation

path

Circular interpolation

plane

Linear interpolation

travel value = Z

1-Z0

11 1

: Indicates setting range (Note)

Positioning speed V

1

Start point

Radius R

Arc auxiliary point

address (X

2, Y2)

Circular interpolation plane

End point address (X

1, Y1)

: Indicates setting range (Note)

Control details for the servo instructions are shown below.

Instruction

Rotation direction

of servomotor

Controllable angle of arc

ABH

Auxiliary point-

specified helical

interpolation

Clockwise (CW)/

Counter

clockwise (CCW)

0° <

360°

(1) The setting range of end point address for the both of circular interpolation axis

and linear interpolation axis is (-2

31

) to (2

31

-1).

(2) The setting range of auxiliary point address is (-2

31

) to (2

31

-1).

(3) The maximum arc radius on the circular interpolation plane is 2

31

-1.

For example, the maximum arc radius for electronic gear 1:1 of unit [mm] is

214748364.7[

µm].