6 -

160

6 POSITIONING CONTROL

[Cautions]

(1) Number of control axes is 1 axis.

(2) Only the absolute data method (ABS) is used for positioning control to the pass

points.

(3) The speed can be changed during the start.

The changed speed is effective until the stop command is input.

(4) Set the positioning address in the servo program using indirect setting with the

word devices D, W and #.

(5) Use only even-numbered devices for indirect setting of positioning address in the

servo program.

If odd-numbered devices are used, an error [141] occurs at the start and control

does not start.

(6) Positioning speeds can be set in the servo program using indirect setting with the

word devices D, W and #.

However, this data is effective only at the position follow-up control start (servo

program start) and the speed does not change if the indirect setting are changed

during the start.

[Program]

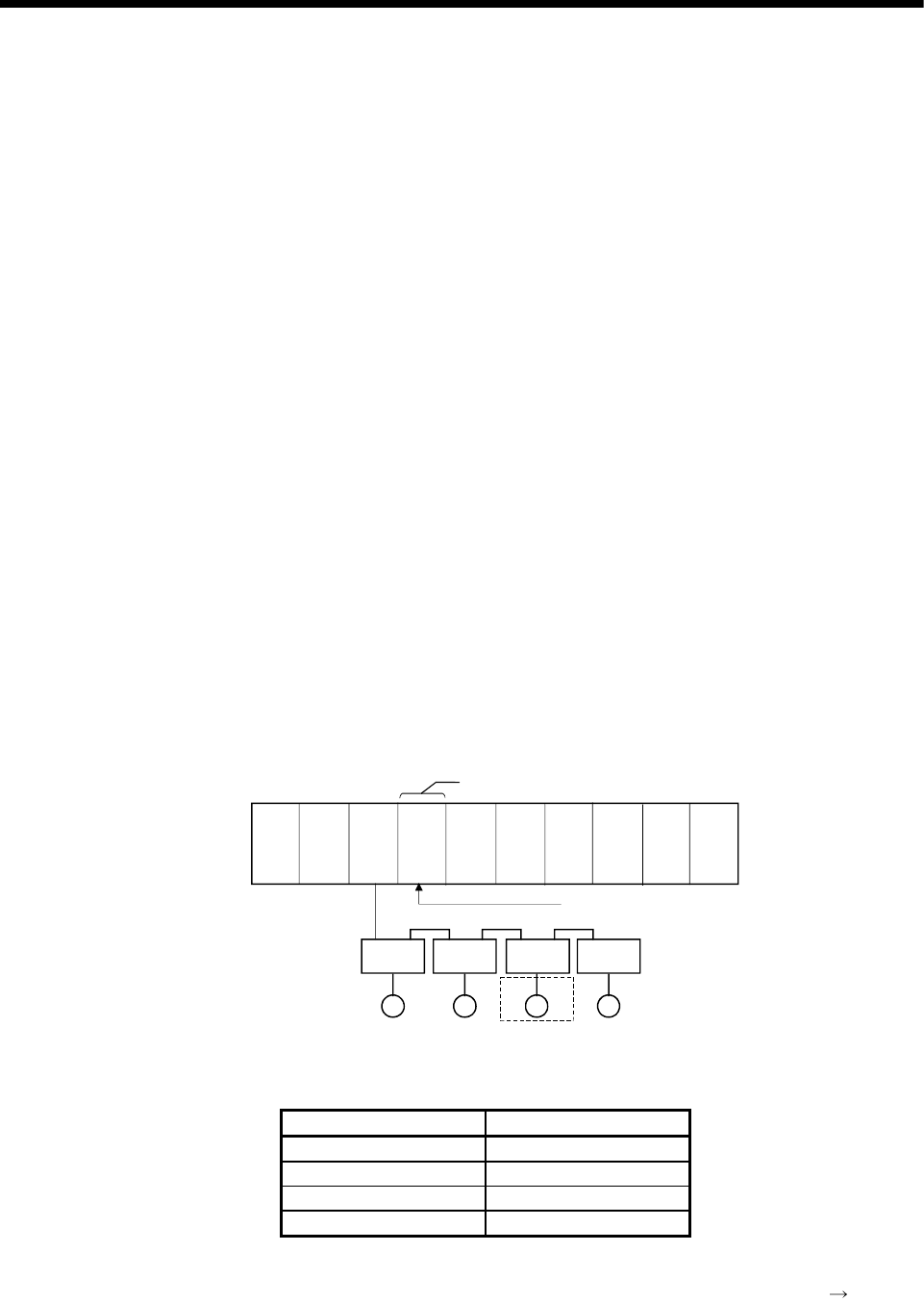

(1) System configuration

Axis 3 position follow-up control for PLC CPU (CPU No.1) to Motion CPU (CPU

No.2).

MM MM

PLC CPU control module

Positioning start command : X0

(PLC CPU device)

Axis

4

Axis

1

Axis

2

Axis

3

AMP AMP AMP AMP

Q61P Q02H

CPU

Q172H

CPU

QX41

(2) Positioning conditions

(a) Position follow-up conditions are shown below.

Item Setting

Servo program No. 100

Control axis Axis 3

Positioning address D4000

Positioning speed 20000

(b) Position follow-up control start command

..............................................................Turning X0 off to on (OFF

ON)

(PLC CPU device)