5 - 18

5 SERVO PROGRAMS FOR POSITIONING CONTROL

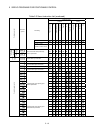

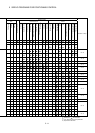

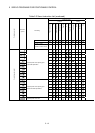

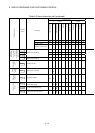

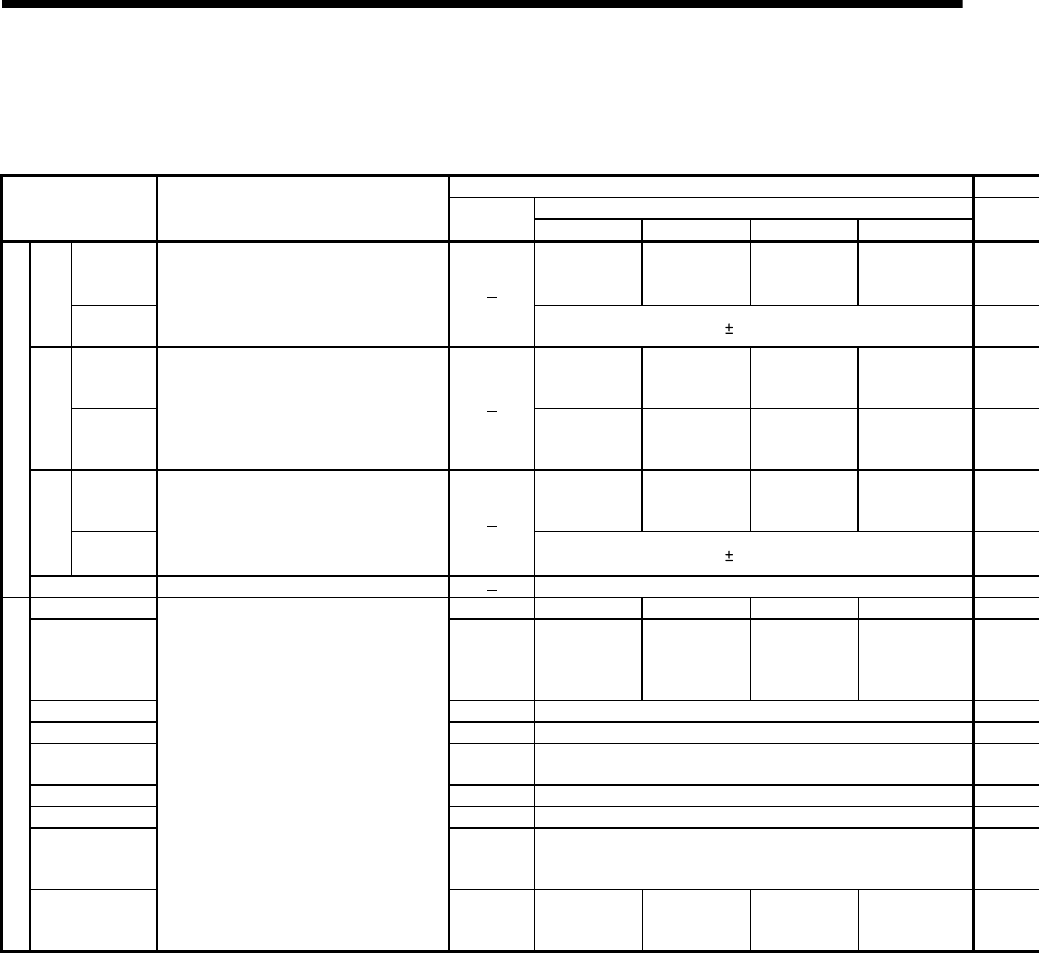

Table 5.3 Positioning data (Continued)

Setting value using a peripheral device

Setting range

Name Explanation

Default

value

mm inch degree PLS

Absolute

data method

-214748364.8 to

214748364.7

[

µ

m]

-21474.83648

to 21474.83647

0 to 359.99999

-2147483648

to 2147483647

Auxiliary

point

Incremental

data method

• Set at the auxiliary point-specified circular

interpolation.

0 to

2147483647

Absolute

data method

0.1 to

429496729.5

[

µ

m]

0.00001 to

42949.67295

0 to 359.99999 1 to 4294967295

Radius

Incremental

data method

• Set at the radius-specified circular

interpolation.

• The sitting ranges depending on the

positioning nethod is shown to the right.

0.1 to

214748364.7

[

µ

m]

0.00001 to

21474.83647

0.00001 to

21474.83647

1 to 2147483647

Absolute

data method

-214748364.8 to

214748364.7

[

µ

m]

-21474.83648

to 21474.83647

0 to 359.99999

-2147483648

to 2147483647

Central point

Incremental

data method

• Set at the central point-specified circular

interpolation.

0 to

2147483647

Circular Interpolation

Number of pitches • Set at the helical interpolation.

0 to 999

Control unit 3 0 1 2 3

Speed limit value

200000

[PLS/s]

0.01 to

6000000.00

[mm/min]

0.001 to

600000.000

[inch/min]

0.001 to

2147483.647

[degree/min]

(Note-5)

1 to

2147483647

[PLS/s]

Acceleration time 1000[ms] 1 to 65535[ms]

Deceleration time 1000[ms] 1 to 65535[ms]

Rapid stop

deceleration time

1000[ms] 1 to 65535[ms]

S-curve ratio 0[%] 0 to 100[%]

Torque limit value 300[%] 1 to 1000[%]

Deceleration

processing on

STOP input

0

0: Deceleration stop based on the deceleration time

1: Deceleration stop based on the rapid stop deceleration time

Parameter block

Allowable error

range for circular

interpolation

• It can be set only items to be changed of the

specified parameter block data.

• Refer to Section 4.3 "Parameter Block" for

details of each data.

100[PLS]

0 to 10000.0

[

µ

m]

0 to 1.00000 0 to 1.00000 0 to 100000