6 - 59

6 POSITIONING CONTROL

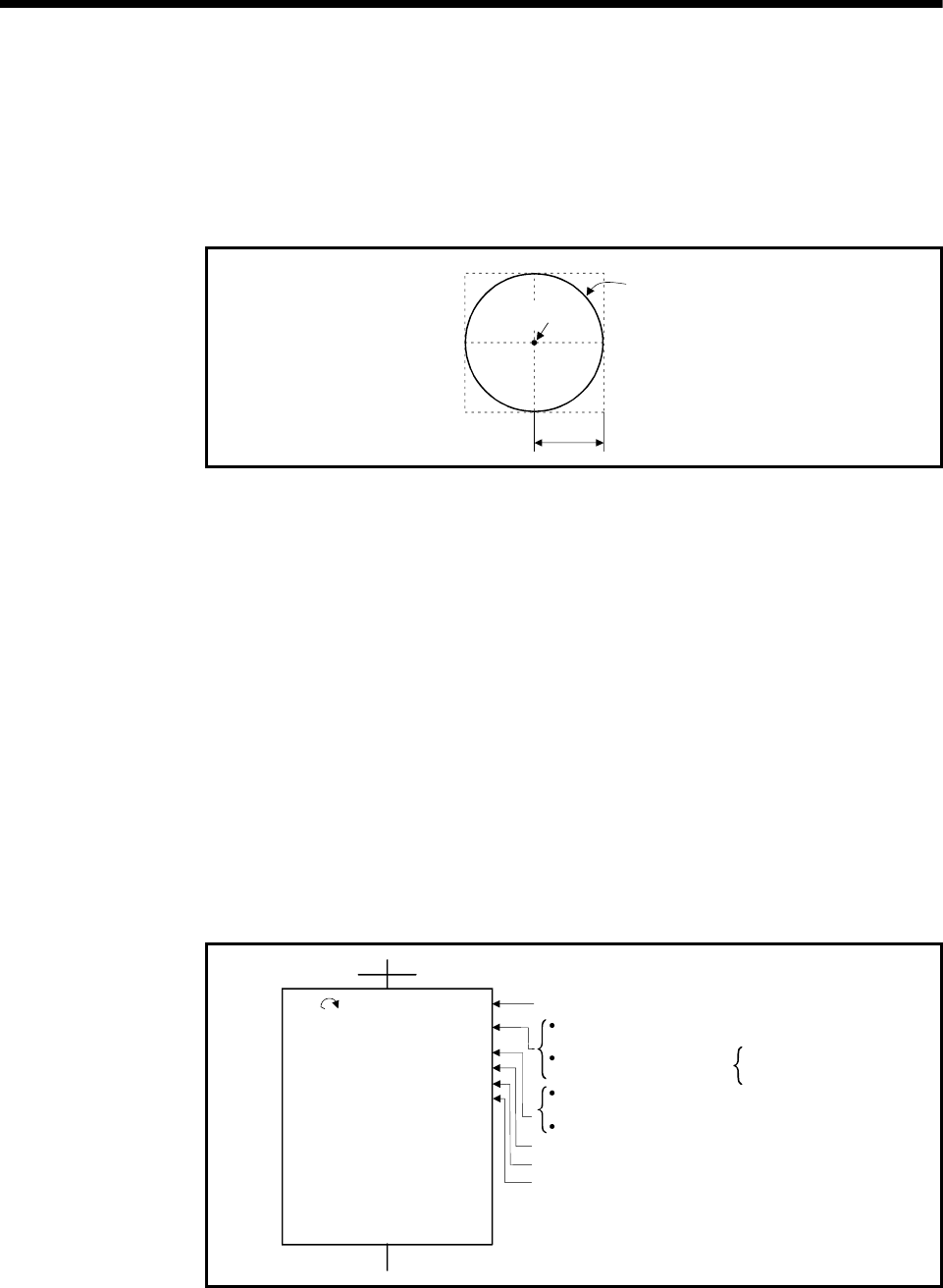

(1) The setting range of end point address for the both of circular interpolation axis

and linear interpolation axis is (-2

31

) to (2

31

-1).

(2) The maximum arc radius on the circular interpolation plane is (2

31

-1).

For example, the maximum arc radius for electronic gear 1:1 of unit [mm] is

214748364.7[

µm].

Maximum arc

2

31

-1-2

31

2

31

-1

0

Radius R

Arc central point

(3) Set the command speed with the combined-speed for 2 axes circular interpolation

axis.

(4) The command speed unit is specified in the parameter block.

(5) Set the number of pitches within the range of 0 to 999. If it is set outside the

setting range, the servo program error [28] occurs, and cannot be started.

(6) All of the circular interpolation axis, linear axis and point address, command

speed, radius (2 word data above) and number of pitches (1 word data) are set

indirectly by D, W and #.

[Program]

(1) Servo program

Servo program No.52 for absolute radius-specified helical interpolation control is

shown below.

<K 52>

ABH

Axis

Axis

Linear axis

Speed

Number of pitches

Radius

1,

2,

3,

100000

50000

25000

1000

100

60000

Axis for the circular . . . . . . . .

interpolation

End point address of the linear axis . . . . . 25000

Positioning speed . . . 1000

Number of pitches . . .

Radius on a circular interpolation plane . . . . . 60000

Axis 1 . . . 100000

Axis 2 . . . . 50000

Linear axis for the circular. . . . . . . . . . . . . Axis 3

interpolation and linear interpolation

End point address of the . . .

circular interpolation axis

100

Axis 1, Axis 2

Absolute radius specified-circular helical interpolation

(Note): Example of the Motion SFC program for positioning control is shown next page.