4 - 14

4 PARAMETERS FOR POSITIONING CONTROL

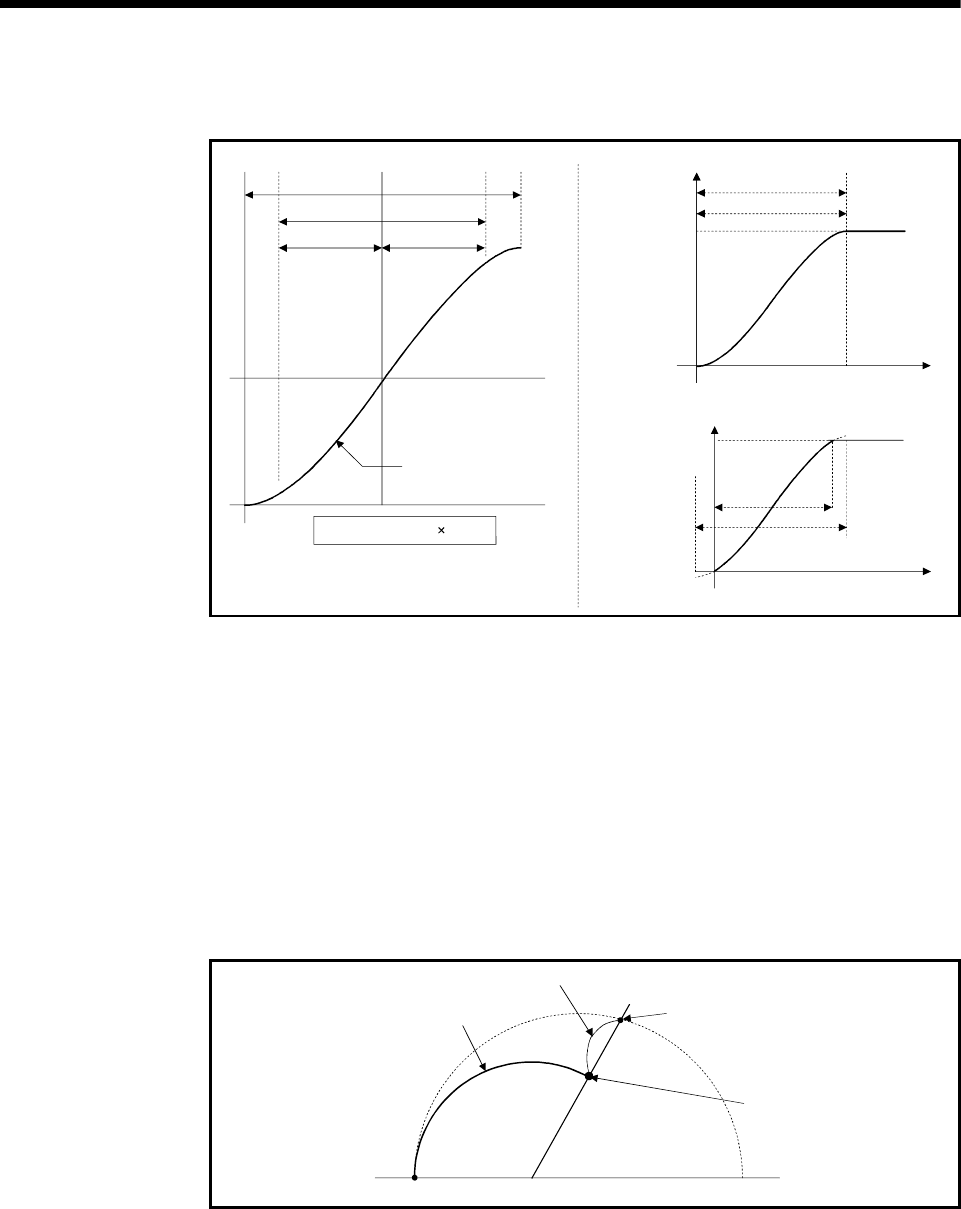

As shown below, the S-curve ratio setting serves to select the part of the sine curve to

be used as the acceleration/deceleration curve.

A

B

B/2 B/2

Sine curve

S-curve ratio = B/A 100[%]

A

B

Positioning speed

B/A=1.0

V

t

Positioning speed

V

A

B

B/A=0.7

S-curve ratio is 100[%]

S-curve ratio is 70[%]

t

4.3.3 Allowable error range for circular interpolation

The locus of the arc calculated from the start point address and central point address

may not coincide with the set end point address for the central-specified control.

The allowable error range for circular interpolation sets the allowable range for the error

between the locus of the arc determined by calculation and the end point address.

If the error is within the allowable range, circular interpolation to the set end point

address is executed while also executing error compensation by means of spiral

interpolation.

If it exceeds the setting range, an error occurs at the start and positioning does not

start. Such an error are set the applicable axis or minor error code area.

Locus determined by spiral

interpolation

Erro

r

End point address

by calculation

Setting end point

address

Start point address Central point address

Fig. 4.4 Spiral Interpolation