1 - 3

1 OVERVIEW

1.2 Features

1.2.1 Performance Specifications

(1) Motion control specifications

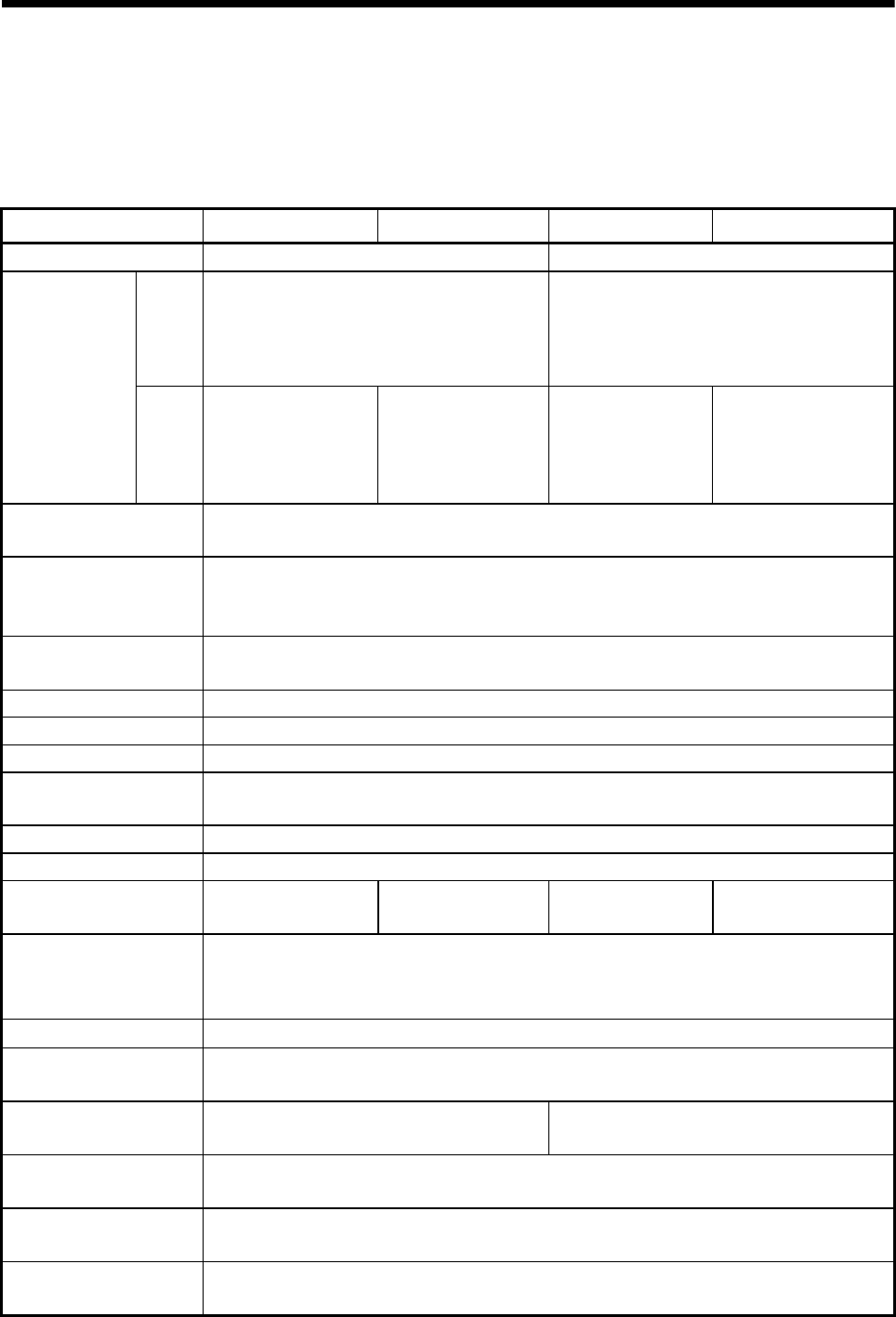

Item Q173HCPU Q173HCPU-T Q172HCPU Q172HCPU-T

Number of control axes Up to 32 axes Up to 8 axes

SV13

0.44ms/ 1 to 3 axes

0.88ms/ 4 to 10 axes

1.77ms/11 to 20 axes

3.55ms/21 to 32 axes

0.44ms/ 1 to 3 axes

0.88ms/ 4 to 8 axes

Operation cycle

(default)

SV22

0.88ms/ 1 to 5 axes

1.77ms/ 6 to 14 axes

3.55ms/15 to 28 axes

7.11ms/29 to 32 axes

——

0.88ms/ 1 to 4 axes

1.77ms/ 5 to 8 axes

——

Interpolation functions

Linear interpolation (Up to 4 axes), Circular interpolation (2 axes),

Helical interpolation (3 axes)

Control modes

PTP(Point to Point) control, Speed control, Speed-position control, Fixed-pitch feed,

Constant speed control, Position follow-up control, Speed control with fixed position stop,

Speed switching control, High-speed oscillation control, Synchronous control (SV22)

Acceleration/

deceleration control

Automatic trapezoidal acceleration/deceleration,

S-curve acceleration/deceleration

Compensation Backlash compensation, Electronic gear, Phase compensation (SV22)

Programming language Motion SFC, Dedicated instruction, Mechanical support language (SV22)

Servo program capacity 14k steps

Number of positioning

points

3200 points

(Positioning data can be designated indirectly)

Programming tool IBM PC/AT

Peripheral I/F USB/SSCNET

Teaching operation

function

None Provided (SV13 use) None Provided (SV13 use)

Home position return

function

Proximity dog type (2 types), Count type (3 types), Data set type (2 types), Dog cradle type,

Stopper type (2 types), Limit switch combined type

(Home position return re-try function provided, home position shift function provided)

JOG operation function Provided

Manual pulse generator

operation function

Possible to connect 3 modules

Synchronous encoder

operation function

Possible to connect 12 modules Possible to connect 8 modules

M-code function

M-code output function provided

M-code completion wait function provided

Limit switch output

function

Number of output points 32 points

Watch data: Motion control data/Word device

Absolute position system

Made compatible by setting battery to servo amplifier.

(Possible to select the absolute data method or incremental method for each axis)