4 - 6

4 PARAMETERS FOR POSITIONING CONTROL

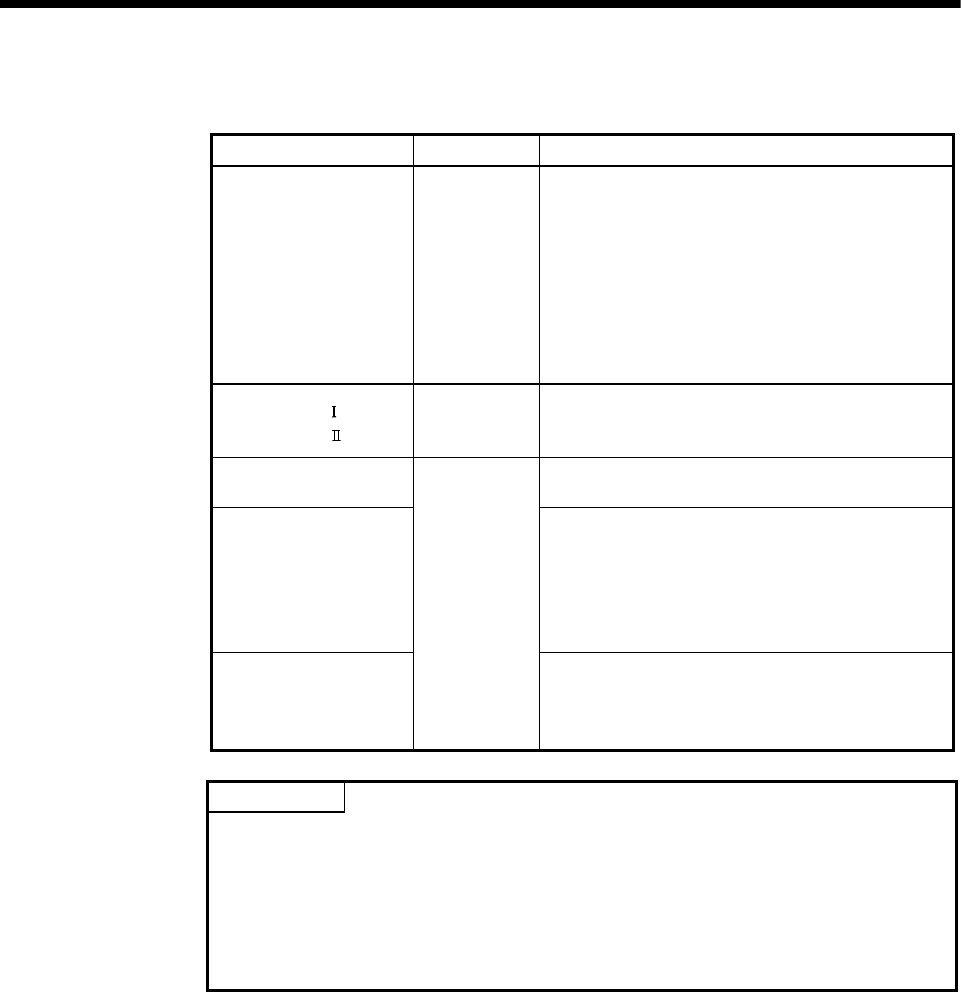

(1) Stroke limit range check

The stroke limit range is checked at the following start or during operation.

Operation start Check Remarks

• Position follow-up control

• Constant-speed control

• Speed switching control

• Positioning control

• Fixed-pitch feed control

Check

• It is checked whether the feed current value is within the

stroke limit range or not at the positioning start. If it

outside the range, an error occurs (error code: 106) and

positioning is not executed.

• If the interpolation path exceeds the stroke limit range

during circular interpolation start, an error occurs (error

codes: 207, 208) and deceleration stop is executed.

• If the current value exceeds the stroke limit range,

deceleration stop is executed.

• Speed control ( )

• Speed control (

)

Not check

• The current value becomes "0", and operation continues

until the external limit signal (FLS, RLS, STOP) is

received.

• Speed/position switching

control (including restart)

• It is checked after the switch to position control.

• JOG operation

• When the current value is executed a deceleration stop

from current command speed, if the current value

exceeds the stroke limit range, a deceleration stop is

made before a stroke limit. (Error code: 207) Travel to

the direction that returns the axis into the stroke range

is possible.

• Manual pulse generator

operation

Check

• If the current value exceeds the stroke limit range, it

stops at stroke limit. (Error code: 207) In this case, a

deceleration stop is not made. Travel to the direction

that returns the axis into the stroke range is possible.

POINTS

(1) Besides setting the upper/lower stroke limit value in the fixed parameters, the

stroke limit range can also be set by using the external limit signals (FLS, RLS).

(2) When the external limit signal turns off, a deceleration stop is executed.

"Deceleration time" and "Rapid stop deceleration time" can be used in the

parameter block for deceleration stop time.