7. Servo Parameters

7.3 MDS-C1-Vx Standard Specification (MDS-B-Vx Compatible)

140

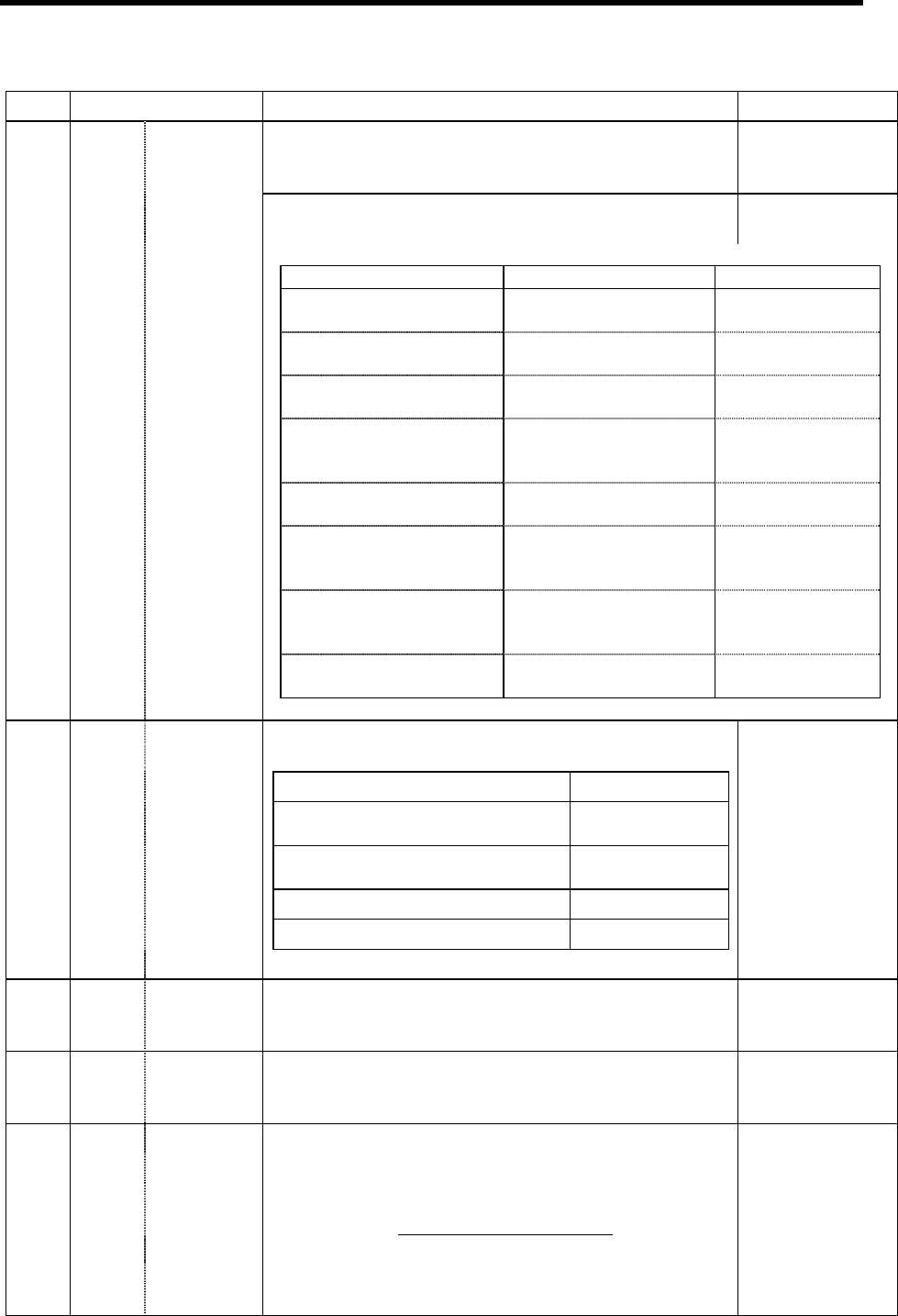

No. Items Details Setting range

2219

(PR)

SV019

RNG1

Position

detector

resolution

In the case of the semi-closed loop control

Set the same value as SV020 (RNG2). (Refer to the

explanation of SV020.)

1 to 9999

(kp/rev)

In the case of the full-closed loop control

Set the number of pulses per ball screw pitch.

1 to 9999

(kp/pit)

Detector model name Resolution SV019 setting

OHE25K-ET,

OHA25K-ET

100,000(p/rev) 100

OSE104-ET,

OSA104-ET

100,000(p/rev) 100

OSE105-ET,

OSA105-ET

1,000,000(p/rev) 1000

Relative position

detection scale

Refer to specification

manual for each

detector

PIT/Resolution

(µm)

AT41 (Mitsutoyo) 1 (µm/p)

The same as

SV018 (PIT)

FME type, FLE type

(Futaba)

Refer to specification

manual for each

detector

PIT/Resolution

(µm)

MP type (Mitsubishi

Heavy Industries)

Refer to specification

manual for each

detector

PIT/Resolution

(µm)

AT342 (Mitsutoyo) 0.5 (µm/p)

Twice as big as

SV018 (PIT)

Set the number of pulses per one revolution of the motor

end detector.

Detector model name SV020 setting

Equipped to HA053, HA13 (Only for

MDS-B-Vx)

10

OHE25K, OHA25K (Only for

MDS-B-Vx)

100

OSE104, OSA104

100

OSE105, OSA105

1000

2220

(PR)

SV020

RNG2

Speed

detector

resolution

1 to 9999

(kp/rev)

2221 SV021

OLT

Overload

detection

time constant

Set the detection time constant of Overload 1 (Alarm 50).

Set to “60” as a standard. (For machine tool builder

adjustment.)

1 to 999

(s)

2222 SV022

OLL

Overload

detection

level

Set the current detection level of Overload 1 (Alarm 50) in

respect to the stall (rated) current. Set to “150” as a

standard. (For machine tool builder adjustment.)

110 to 500

(Stall [rated]

current %)

Set the excessive error detection width when servo ON.

<Standard setting value>

Rapid traverse rate

(mm/min)

OD1=OD2=

60*PGN1

/2 (mm)

2223 SV023

OD1

Excessive

error

detection

width during

servo ON

When “0” is set, the excessive error detection will not be

performed.

0 to 32767

(mm)