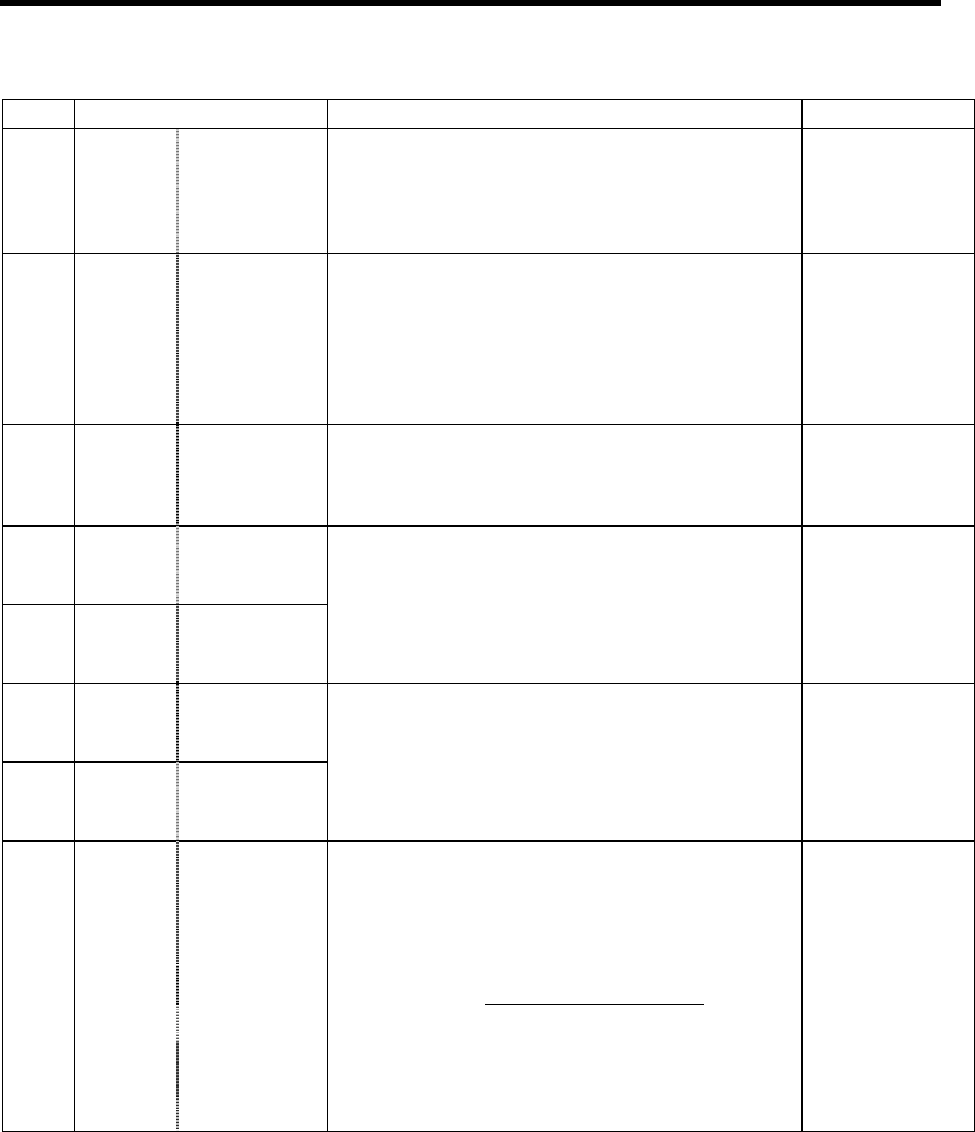

7. Servo Parameters

7.2 MDS-C1-Vx High-gain (MDS-B-Vx4 Compatible)

125

No. Items Details Setting range

2258 SV058

SHGCsp

SHG control

gain in spindle

synchronous

control

Set this with SV049 (PGN1sp) and SV050 (PGN2sp)

if you wish to perform the SHG control in the spindle

synchronous control (synchronous tapping,

synchronous control with spindle/C axis).

When not performing the SHG control, set to “0”.

0 to 1200

(rad/s)

2259 SV059

TCNV

Collision

detection

torque

estimating gain

Set the torque estimating gain when using the

collision detection function.

After setting as SV035/bitF(clt)=1 and performing

acceleration/deceleration, set the value displayed in

MPOS of the NC servo monitor screen.

Set to “0” when not using the collision detection

function.

-32768 to 32767

2260 SV060

TLMT

Collision

detection level

When using the collision detection function, set the

collision detection level during the G0 feeding.

If “0” is set, none of the collision detection function

will work.

0 to 999

(Stall [rated]

current %)

2261 SV061

DA1NO

D/A output

channel 1 data

No.

2262 SV062

DA2NO

D/A output

channel 2 data

No.

Input the data number you wish to output to D/A

output channel.

In the case of MDS-C1-V2, set the axis on the side to

which the data will not be output to “-1”.

-1 to 127

2263 SV063

DA1MPY

D/A output

channel 1

output scale

2264 SV064

DA2MPY

D/A output

channel 2

output scale

Set the scale with a 1/256 unit.

When “0” is set, output is done with the standard

output unit.

-32768 to 32767

(Unit: 1/256)

Set the spring constant of the tool end

compensation.

In the semi-closed loop control, the tool end

compensation amount is calculated with the

following equation.

F (mm/min)

2

*SV065

Compensation

amount=

R (mm)*10

9

(µm)

F: Commanded speed

R: Radius

2265 SV065

TLC

Tool end

compensation

spring constant

When not using, set to “0”.

-32768 to 32767