M400E Ozone Analyzer Operator’s Manual Optional Hardware and Software

The state of the Sample/Cal valves can be controlled:

Manually via the analyzer’s front panel;

By activating the instrument’s AutoCal

feature (See Section 9.4);

Remotely by using the External Digital I/O Control Inputs (See Section 9.3), or;

Remotely via the RS-232/485 Serial I/O ports (See Section 8.1.7).

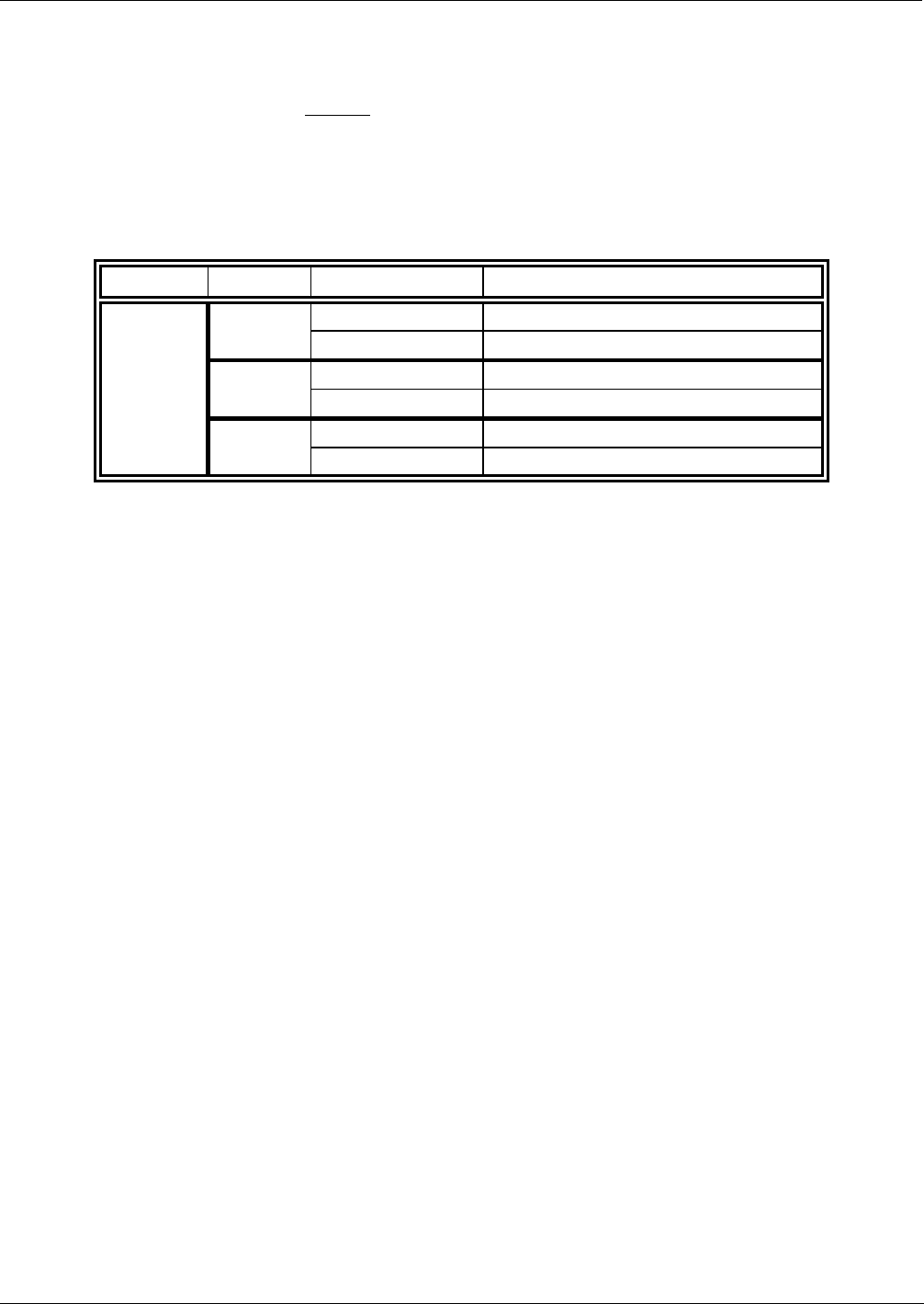

Table 5-2:

Internal Zero/Span Valve Operating States

Option Mode Valve Condition

Sample/Cal Valve Open to SAMPLE inlet

SAMPLE

Ozone Generator OFF

Sample/Cal Valve Open to Ozone Generator

ZERO

CAL

Ozone Generator OFF

Sample/Cal Valve Open to Ozone Generator

51A

SPAN

CAL

Ozone Generator ON at intensity level set by user

5.6.2.1. Disposable Charcoal O

3

Filter

M400E’s equipped with IZS options have a disposable filter that is used by the instrument for creating zero air for

the auto-cal zero-point calibration. This filter is filled with activated charcoal and should last for approximately 1

year of continual usage. Call Teledyne Instruments customer service for replacement filters.

5.6.3. METAL WOOL SCRUBBER (OPT 68)

This option replaces the standard scrubber with a heated Metal Wool Scrubber that works similarly to the

catalytic converters found on many automobile’s exhaust systems and improves the analyzer’s performance in

certain higher humidity applications.

5.6.4. IZS DESICCANT (OPTION 56)

The M400E can be fitted with a desiccant dryer to provide a dry air source to the IZS sub-system. This option

consists of a rear panel mounted scrubber cartridge filled with anhydrous calcium sulfate (CaSO4) desiccant.

The desiccant material is expendable and must be replaced at regular intervals.

The material exhibits a color change when it has been saturated with water vapor, turning from blue to

pink.

The scrubber cartridge should be refilled before the entire scrubber turns pink.

Replacement interval will depend on how often the IZS is used, as well as ambient levels of humidity in

your application.

Initially the desiccant should be frequently monitored until a standard replacement interval can be

established.

04315 Rev. C1 53