Getting Started M400E Ozone Analyzer Operator’s Manual

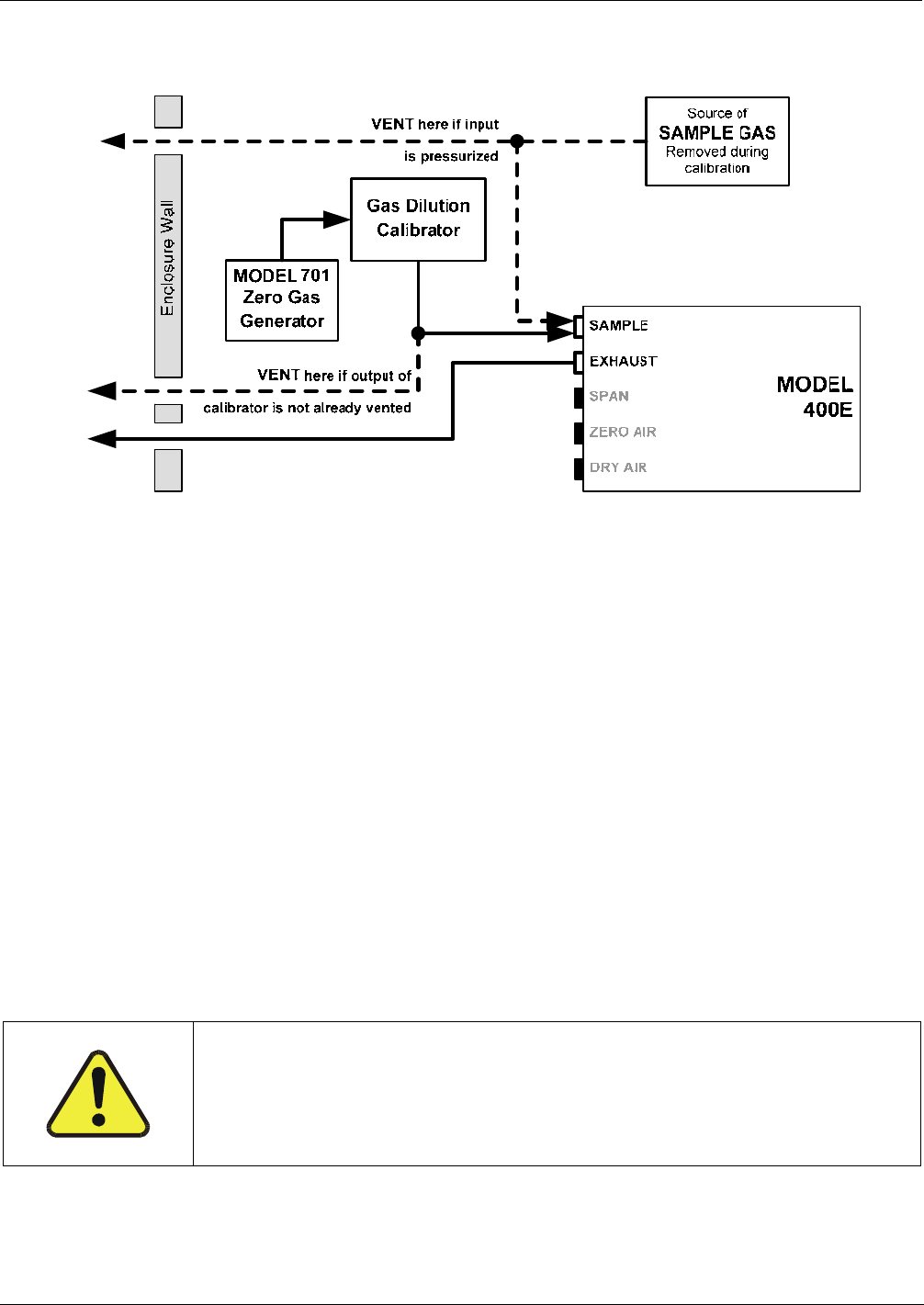

3.4.2. BASIC PNEUMATIC SETUP FOR THE M400E ANALYZER

Figure 3-10: Gas Line Connections for the M400E Analyzer – Basic Configuration

For the Model 400E photometric ozone analyzer in its basic configuration (i.e. without the optional internal zero

air source or valves), attach the following pneumatic lines:

1. SAMPLE GAS SOURCE: Attach a sample inlet line to the sample inlet fitting.

Sample Gas pressure must equal ambient atmospheric pressure (1.0 psig)

In applications where the sample gas is received from a pressurized manifold, a vent must be placed

on the sample gas line. This vent line must be:

At least 0.2m long

No more than 2m long

Vented outside the shelter or immediate area surrounding the instrument

2. CAL GAS & ZERO AIR SOURCES: The source of calibration gas is also attached to the SAMPLE

inlet, but only when a calibration operation is actually being performed.

3. EXHAUST OUTLET: Attach an exhaust line to the EXHAUST outlet fitting.

The exhaust line should be a maximum of 10 meters of ¼” PTEF tubing.

CAUTION

General Safety Hazard

VENTING SHOULD BE OUTSIDE THE SHELTER OR IMMEDIATE AREA

SURROUNDING THE INSTRUMENT AND CONFORM TO ALL SAFETY

REQUIREMENTS REGARDING EXPOSURE TO O

3

.

4. Once the appropriate pneumatic connections have been made, check all pneumatic fittings for leaks

using the procedures defined in Section 12.3.4.

22 04315 Rev. C1