M400E Ozone Analyzer Operator’s Manual 346BEPA Protocol Calibration

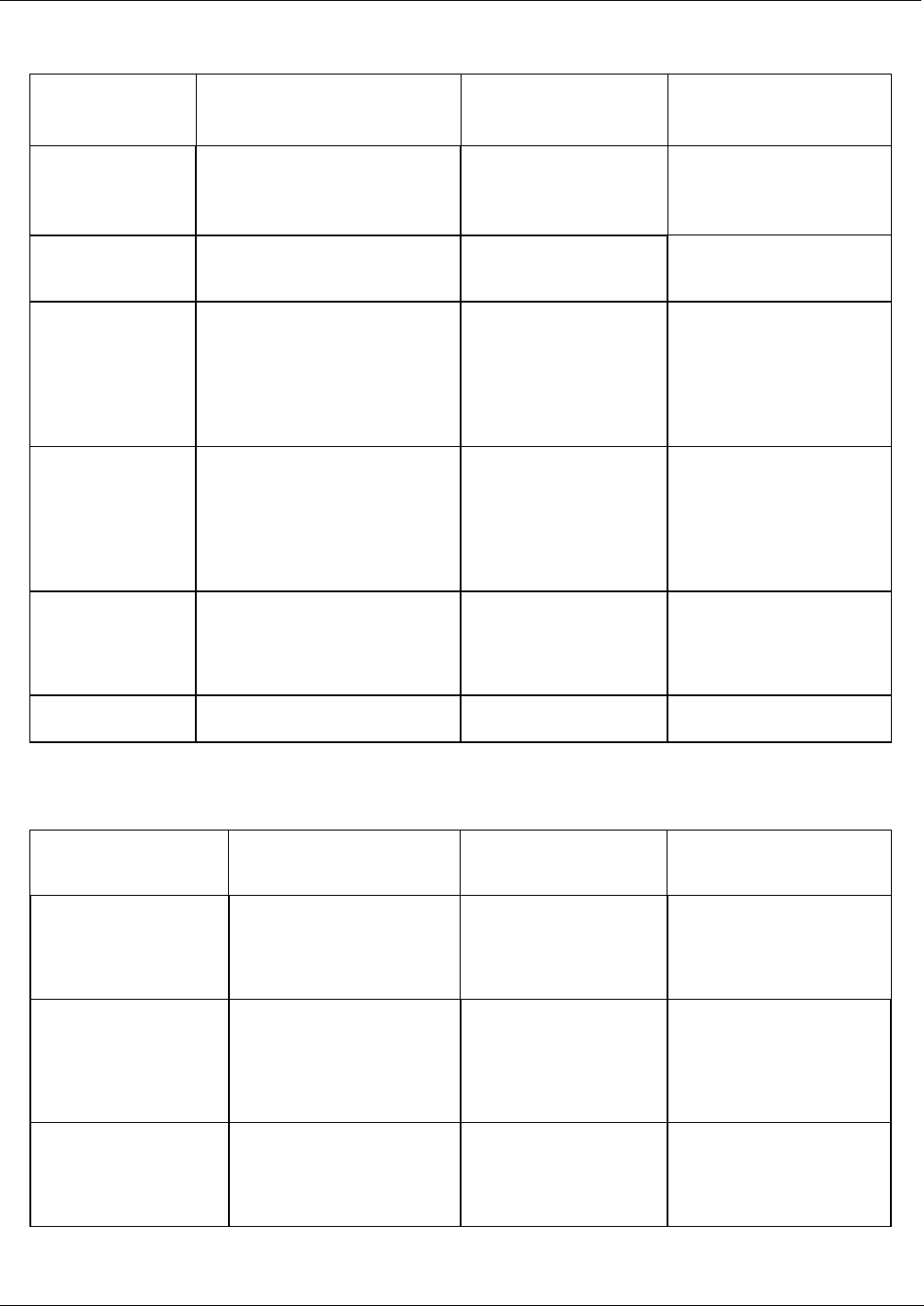

Table 10-1: Daily Activity Matrix

CHARACTERISTIC ACCEPTANCE LIMITS

FREQUENCY AND

METHOD OF

MEASUREMENT

ACTION IF

REQUIREMENTS ARE

NOT MET

Shelter

Temperature

Mean temperature between 22C

and 28C (72F and 82F), daily

fluctuations not greater than

2C.

Check thermograph chart

daily for variations not

greater than 2C (4F).

Mark strip chart for the

affected time period.

Repair/adjust temp control.

Sample

Introduction

System

No moisture, foreign material,

leaks, obstructions; sample line

connected to manifold.

Weekly visual inspection.

Clean, repair or replace as

needed.

Recorder

Adequate ink supply and chart

paper.

Legible ink traces.

Correct settings of chart speed

and range switches.

Correct time.

Weekly visual inspection.

Replenish and chart paper

supply

Adjust recorder time to

agree with clock note on

chart.

Analyzer

Operational

Settings

Flow and regulator indicators at

proper settings.

Temperate indicators cycling or

at proper levels.

Analyzer in sample mode.

Zero/span controls locked.

Weekly visual inspection. Adjust or repair as needed.

Analyzer

Operational Check

Zero and span within tolerance

limits as described in Subsec.

9.1.3 of Sec. 2.0.9

(Ref. 11).

Level 1 zero and span

every 2 weeks; Level 2

between Level 1 checks

at frequency desired by

user.

Isolate source error, and

repair.

After corrective action,

recalibrate analyzer.

Precision Check

Assess precision as described in

Sec. 2.0.8 (Ref. 11).

Every 2 weeks,

Sec. 2.0.8 (Ref. 11).

Calculate, report precision,

Sec. 2.0.8 (Ref. 11).

Table 10-2: Activity Matrix for Audit Procedure

AUDIT ACCEPTANCE LIMITS

FREQUENCY AND

METHOD OF

MEASUREMENT

ACTION IF REQUIREMENTS

ARE NOT MET

Multipoint calibration

audit

The difference between the

measured and the audit

values as a measure of

accuracy (Sec. 2.0.8 of Ref.

11).

At least once a quarter

(Sec. 2.0.8 of Ref. 11)

Re-calibrate the analyzer.

Data processing audit

Adhere to stepwise

procedure for data reduction

(Sec. 8.4); no difference

exceeding

0.02 ppm.

Perform independent

check on a sample of

recorded data, e.g.,

1 day out of every 2

weeks of data, 2 hours for

each day.

Check all remaining data if

one or more audit checks

exceeds 0.02 ppm.

Systems audit

Method described in this

section of the Handbook.

At the startup of a new

monitoring system, and

periodically as

appropriate; observation

and checklist.

Initiate improved methods

and/or training programs.

04315 Rev. C1 183