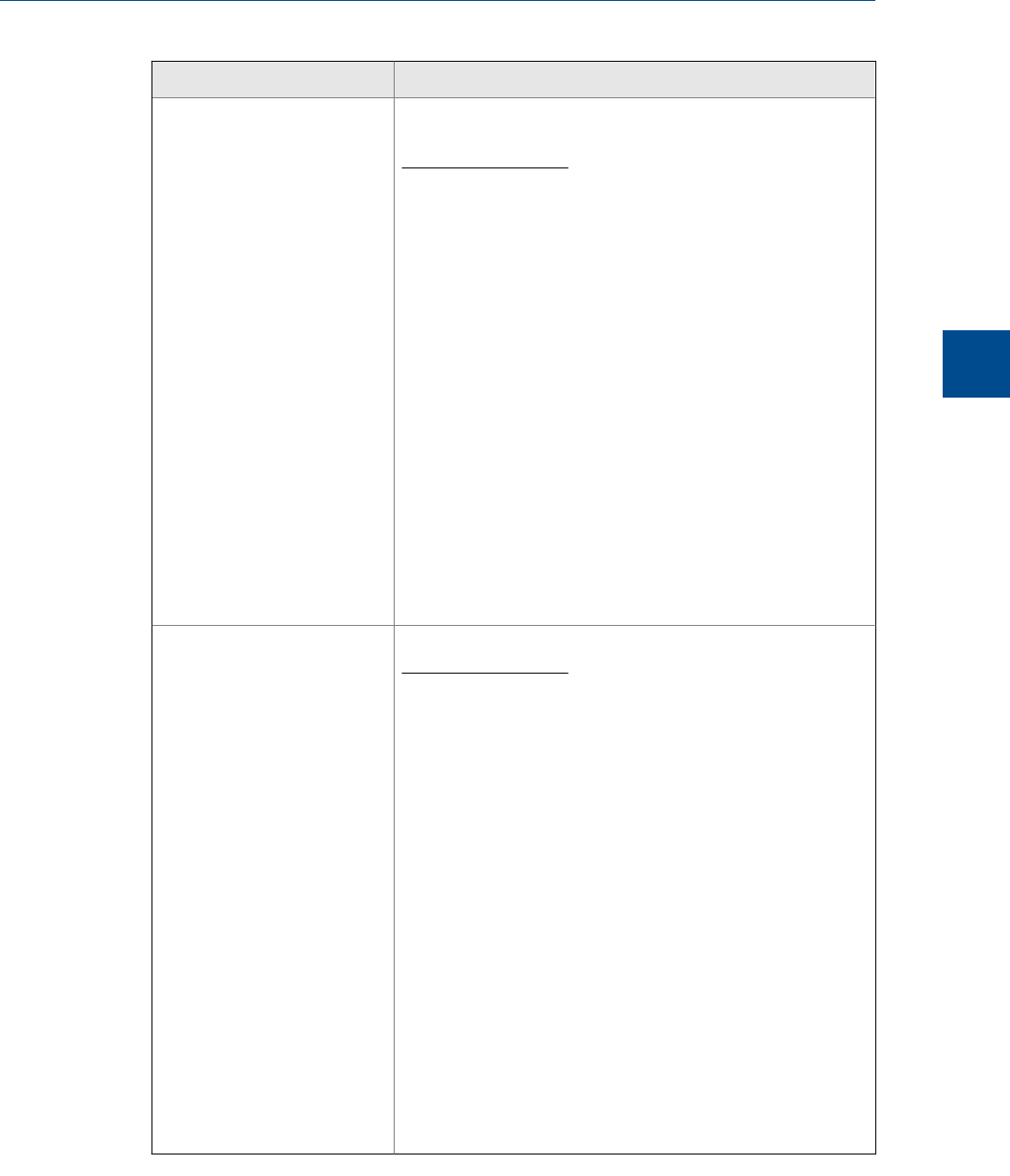

Alarm Name Possible Causes/Solution

Stream 1 Validation Failure

Stream 2 Validation Failure

Stream 3 Validation Failure

Stream 4 Validation Failure

Stream 5 Validation Failure

Stream 6 Validation Failure

Stream 7 Validation Failure

Stream 8 Validation Failure

Stream 9 Validation Failure

Stream 10 Validation Failure

Stream 11 Validation Failure

Stream 12 Validation Failure

Stream 13 Validation Failure

Stream 14 Validation Failure

Stream 15 Validation Failure

Stream 16 Validation Failure

Stream 17 Validation Failure

Stream 18 Validation Failure

Stream 19 Validation Failure

Stream 20 Validation Failure

The most recent validation sequence for the indicated stream

failed.

Recommended actions:

1. Check that the validation gas cylinder isolation valves are

open.

2. Check that the validation gas regulators are set properly.

3. If the validation gas regulator is below the set point, replace

the gas bottle with a full one.

4. If the gas used for validation is the same as the gas that is

used for calibration, ensure that the cylinder gas composition

value listed on the cylinder's tag or on the certificate of analy-

sis received from the supplier matches the value displayed in

MON2020's Component Data table.

5. Re-run the validation sequence.

6. If still unsuccessful contact your Emerson Process Manage-

ment representative.

Stream 1 RF Deviation

Stream 2 RF Deviation

Stream 3 RF Deviation

Stream 4 RF Deviation

Stream 5 RF Deviation

Stream 6 RF Deviation

Stream 7 RF Deviation

Stream 8 RF Deviation

Stream 9 RF Deviation

Stream 10 RF Deviation

Stream 11 RF Deviation

Stream 12 RF Deviation

Stream 13 RF Deviation

Stream 14 RF Deviation

Stream 15 RF Deviation

Stream 16 RF Deviation

Stream 17 RF Deviation

Stream 18 RF Deviation

Stream 19 RF Deviation

Stream 20 RF Deviation

The most recent calibration sequence failed.

Recommended actions:

1. Check that the calibration gas cylinder isolation valves are

open.

2. Check that the calibration gas regulators are set properly and

that the cylinder is not below the set point. If the cylinder is

below the set point, replace it with a full cylinder.

3. Verify that the calibration cylinder gas composition value lis-

ted on the cylinder tag or on the certificate of analysis re-

ceived from supplier matches the calibration cylinder gas

composition value displayed in MON2020's Component Data

table. If there is a mismatch, edit the Component Data table

to reflect the correct value. Re-run the calibration sequence.

4. If still unsuccessful contact your Emerson Process Manage-

ment representative.

Operation and maintenance

4

Operation and maintenance

85