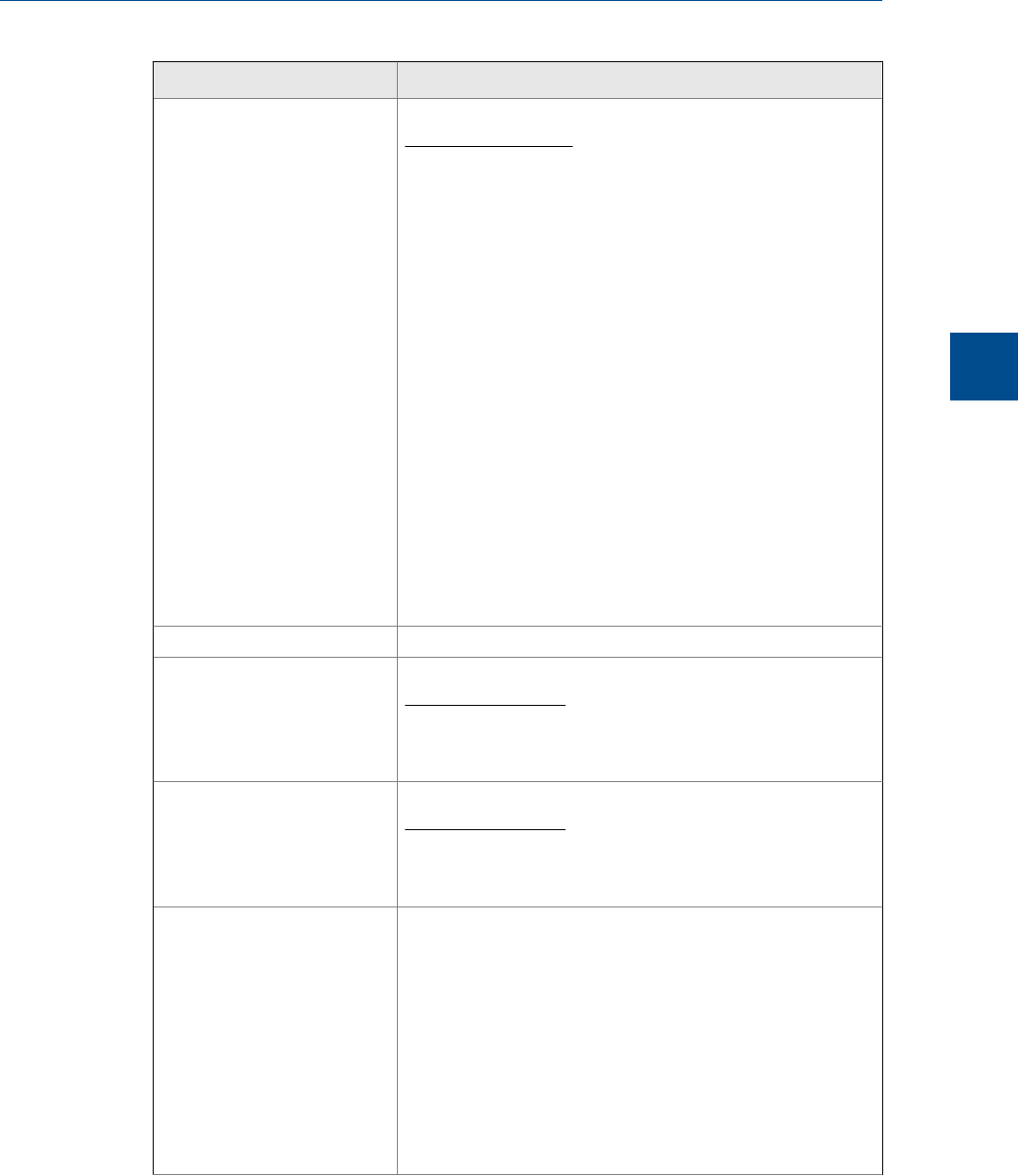

Alarm Name Possible Causes/Solution

No sample flow 1

(Applies to the optional sample

flow switch.)

There is no sample flow in the GC.

Recommended actions:

Check sample gas rotometer in the sample conditioning system

for flow and do one of the following:

If no gas flow or no rotometer is present, do the following:

1. Confirm that there is gas flow at the sample point location.

2. Check that the sample valves in the sample conditioning sys-

tem are open.

3. Check that the bypass return vent path is free of obstruction.

4. Confirm that the sample line is connected from the sample

point to the GC’s sample conditioning system and is free of

obstructions.

5. Close the valve at the sample tap, remove pressure from the

line and check the filters at the probe or the sample condi-

tioning system or both. If they are filled with liquids or partic-

ulates, replace the filtering elements.

If automatic stream selection valves are present, confirm that

they are operating properly.

If a slight sample gas flow is present at the rotometer in the sam-

ple conditioning system, drain or replace all filters.

If flow is observed in the rotometer, replace the sample flow

switch because it might have failed.

No sample flow 2 Refer to “No sample flow 1”.

Low Carrier Pressure 1 Input carrier pressure for detector 1 is below the preset limit.

Recommended action: Check that the carrier cylinder pressure is

10 psi (or greater) above the mechanical regulator set point. If in-

put carrier pressure is low, check the carrier cylinder pressure.

Replace carrier gas cylinder if required.

Low Carrier Pressure 2 Input carrier pressure for detector 2 is below the preset limit.

Recommended action: Check that the carrier cylinder pressure is

10 psi (or greater) above the mechanical regulator set point. If in-

put carrier pressure is low, check the carrier cylinder pressure.

Replace carrier gas cylinder if required.

Analog Input 1 High Signal

Analog Input 2 High Signal

Analog Input 3 High Signal

Analog Input 4 High Signal

Analog Input 5 High Signal

Analog Input 6 High Signal

Analog Input 7 High Signal

Analog Input 8 High Signal

Analog Input 9 High Signal

Analog Input 10 High Signal

Measured value for the indicated analog input is greater than the

user-defined full scale range.

Operation and maintenance

4

Operation and maintenance

83