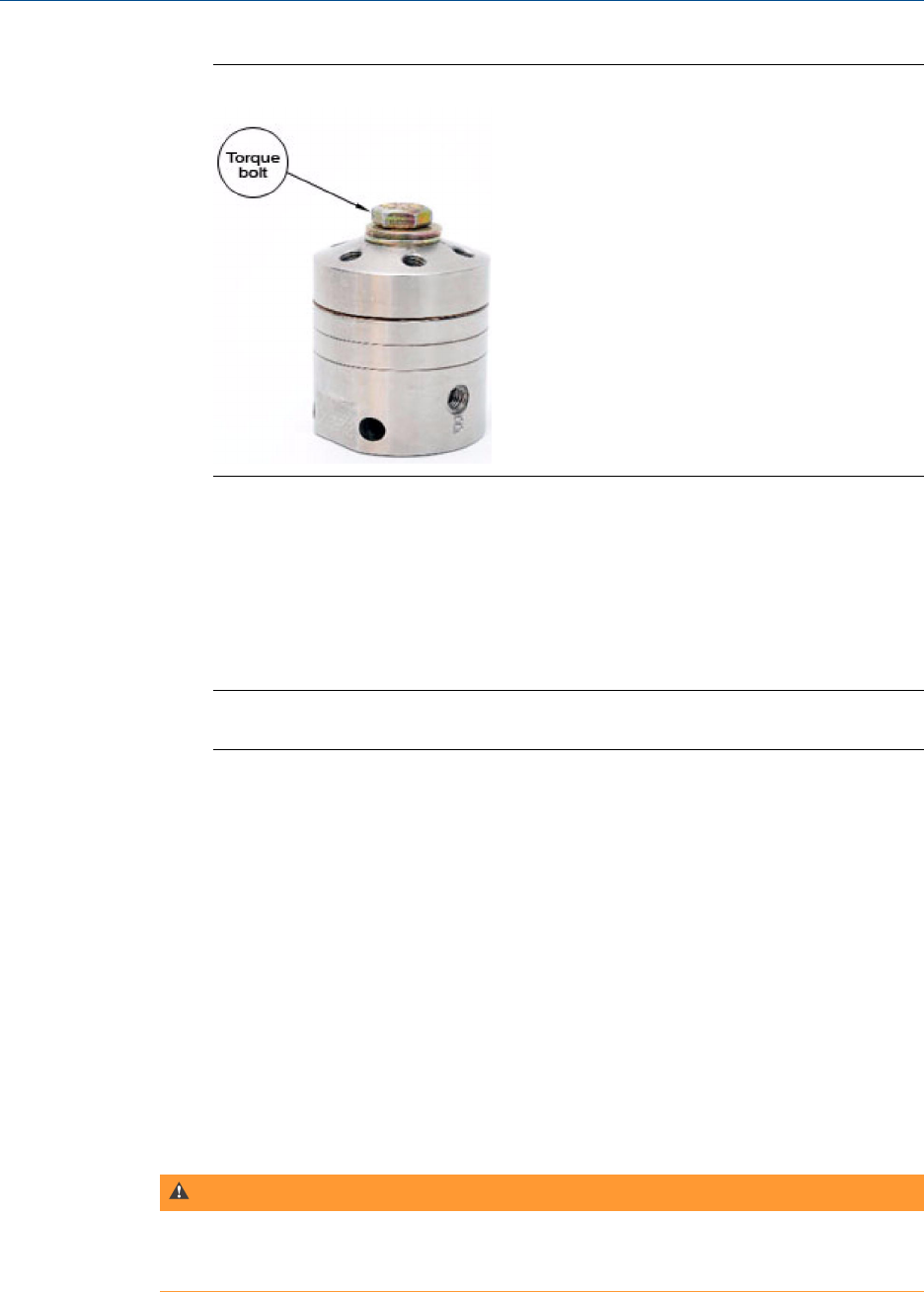

The torque boltFigure 4-5:

8. Holding the lower piston plate, pull the valve straight off the block. The alignment

pins may stick slightly.

9. Remove and discard the old valve diaphragms and gaskets.

10. Clean the sealing surface as required using a non-lint-forming cloth and isopropyl

alcohol. Blow the sealing surface with clean, dry instrument air or carrier gas. Dirt

including dust and lint can cause troublesome leakage.

Note

Do not use an oil-based cleaner on the valve.

11. Replace the old diaphragms and gaskets, in the same order, with the new ones

supplied.

12. Reinstall the valve using the following steps:

a. Align the pins with holes in the block and push the valve assembly into place.

b. Tighten the valve’s torque bolt. The 6-port valve requires 20 ft/lb of torque; the

10-port valve requires 30 ft/lb of torque.

c. Return the valve to the assembly.

d. Reconnect all fittings and tubing.

Removing and replacing solenoids

Both the oven system solenoids and the stream switching solenoids can be replaced by

using the following procedure.

WARNING!

Disconnect all electrical power to the unit and ensure the area is free of explosive gases. Failure

to follow this warning may result in injury or death to personal or cause damage to the

equipment.

Operation and maintenance

92