B.3 Replacing carrier cylinder

To replace one carrier cylinder without interrupting GC operation, proceed as follows:

1. Turn cylinder valve off.

2. Back off on cylinder pressure regulator until handle turns freely.

3. Remove cylinder.

4. Attach new cylinder to regulator and repeat Steps 3 through 7 of Section B.2, using

appropriate bleed valve to purge line.

5. Leak-check the fitting.

6. Open the appropriate block valve to the analyzer (V-2 or V-3) and regulate outlet

pressure to appropriate level. (See Steps 14 and 15 of Section B.2.)

B.4 Calibration gas

The calibration gas used for BTU analysis should be blended of gases specified as Primary

Standards. Primary Standard gases are blended using weights that are traceable to the

National Institute of Standards and Technology (N.I.S.T). For other applications, the

calibration gas should be blended to the specifications detailed in the analyzer’s

Application Data Sheets.

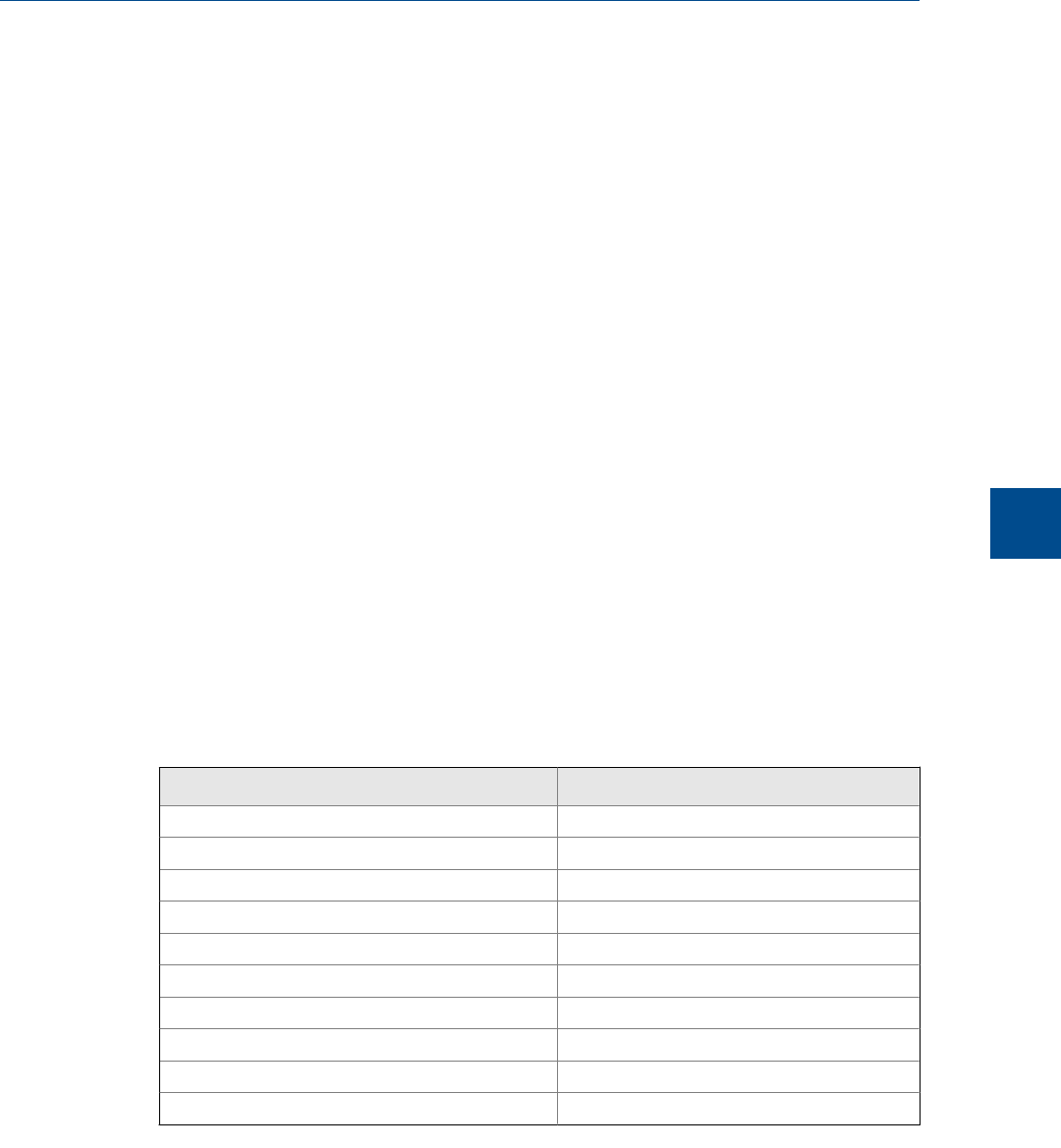

The calibration gas should not have any component that could drop out at the coldest

temperature to which the gas will be subjected. A typical blend for a temperature of zero

degrees Fahrenheit is listed in the following table. No dropout will occur in this calibration

gas if it is blended at a pressure below 250 psig.

Gas Mole Percent

Nitrogen 2.5

Carbon Dioxide 0.5

Methane Balance

Propane 1.0

Isobutane 0.3

N-butane 0.3

Neopentane 0.1

Isopentane 0.1

N-pentane 0.1

N-hexane 0.03

The sampling system should be carefully planned for the best chromatographic analyses.

Carrier gas installation and maintenance

B

Carrier gas installation and maintenance

177