229

11.2. PREDICTIVE DIAGNOSTICS

Predictive diagnostic functions including failure warnings and alarms built into the

analyzer’s firmware allow the user to determine when repairs are necessary without

performing painstaking preventative maintenance procedures.

The Test Functions can also be used to predict failures by looking at how their values

change over time. Initially it may be useful to compare the state of these Test Functions

to the values recorded on the printed record of the final calibration performed on your

instrument at the factory, P/N 04314. The following table can be used as a basis for

taking action as these values change with time. The internal data acquisition system

(DAS) is a convenient way to record and track these changes. Use APICOM to

download and review this data from a remote location.

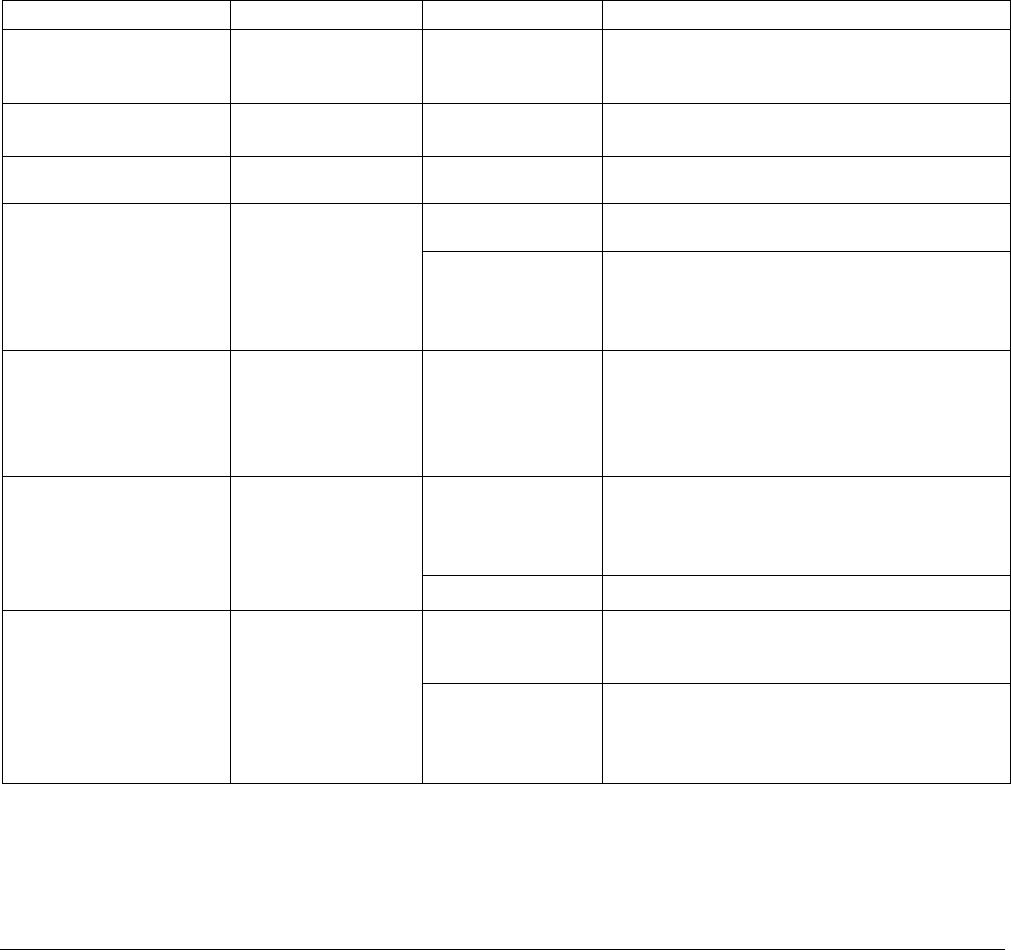

Table 11-2: Predictive Uses for Test Functions

FUNCTION MODE BEHAVIOR INTERPRETATION

STABIL ZERO CAL

Increasing

Pneumatic leaks – instrument & sample

system

Malfunctioning UV lamp (Bench)

O3 REF SAMPLE

Decreasing

UV lamp ageing

Mercury contamination

O3 DRIVE CALS

Increasing

Ageing IZS UV lamp (only if reference

detector option is installed)

Increasing > 1”

Pneumatic Leak between sample inlet and

optical bench

PRES SAMPLE

Decreasing > 1”

Dirty particulate filter

Pneumatic obstruction between sample inlet

and optical bench

Obstruction in sampling manifold

SAMP FL SAMPLE

Decreasing

Pump diaphragm deteriorating

Sample flow orifice plugged/obstructed

Pneumatic obstruction between sample inlet

and optical bench

Obstruction in sampling manifold

Increasing

Pneumatics becoming contaminated/dirty

Dirty particulate filter

Pneumatic leaks – instrument & sample

system

SLOPE SPAN CAL

Decreasing

Contaminated calibration gas

Increasing

Obstructed/leaking Meas/Ref Valve

Pneumatic leaks – instrument & sample

system

OFFSET ZERO CAL

Decreasing

Contaminated zero calibration gas

Obstructed Meas/Ref Valve

Pneumatic leaks – instrument & sample

system

06870C DCN6332