225

11. INSTRUMENT MAINTENANCE

For the most part, the T400 analyzer is maintenance free, there are, however, a minimal

number of simple procedures that when performed regularly will ensure that the T400

photometer continues to operate accurately and reliably over its lifetime.

Repairs and troubleshooting are covered in Section12 of this manual.

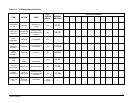

11.1. MAINTENANCE SCHEDULE

Table 11-1 shows a typical maintenance schedule for the T400. Please note that in

certain environments (i.e. dusty, very high ambient pollutant levels) some maintenance

procedures may need to be performed more often than shown.

Note A span and zero calibration check (see CAL CHECK REQ’D Column of

Table 9-1) must be performed following some of the maintenance

procedures listed below.

- To perform a CHECK of the instrument’s Zero or Span Calibration

follow the same steps as described in Section 9.3.

- DO NOT PRESS THE ENTR BUTTON

at the end of each operation.

Pressing the ENTR button resets the stored values for OFFSET and

SLOPE and alters the instruments Calibration.

- Alternatively, use the Auto cal feature described in Section9.4 with the

wi

th the CALIBRATE ATTRIBUTE SET TO OFF

WARNING - Electrical Shock Hazard

RISK OF ELECTRICAL SHOCK. DISCONNECT POWER BEFORE PERFORMING

ANY OF THE FOLLOWING OPERATIONS THAT REQUIRE ENTRY INTO THE

INTERIOR OF THE ANALYZER.

CAUTION

Qualified Personnel

THE OPERATIONS OUTLINED IN THIS SECTION ARE TO BE PERFORMED BY

QUALIFIED MAINTENANCE PERSONNEL ONLY.

06870C DCN6332