EPA Protocol Calibration T400 Ozone Analyzer Operator’s Manual

218

10.5. SUMMARY OF QUALITY ASSURANCE CHECKS

Essential to quality assurance are scheduled checks for verifying the operational status

of the monitoring system:

The operator should visit the site at least once each week.

A Level 1 zero and span check must be made on the analyzer every two weeks.

Level 2 zero and span checks should be conducted at a frequency desired by the

user.

In addition, an independent precision check between 0.08 and 0.10 ppm may be required

at least once every two weeks.

Table 10-1 summarizes the quality assurance activities for routine operations. A

discussion of

each activity appears in the following sections.

To provide for documentation and accountability of activities, a checklist should be

compiled and then filled out by the field operator as each activity is completed.

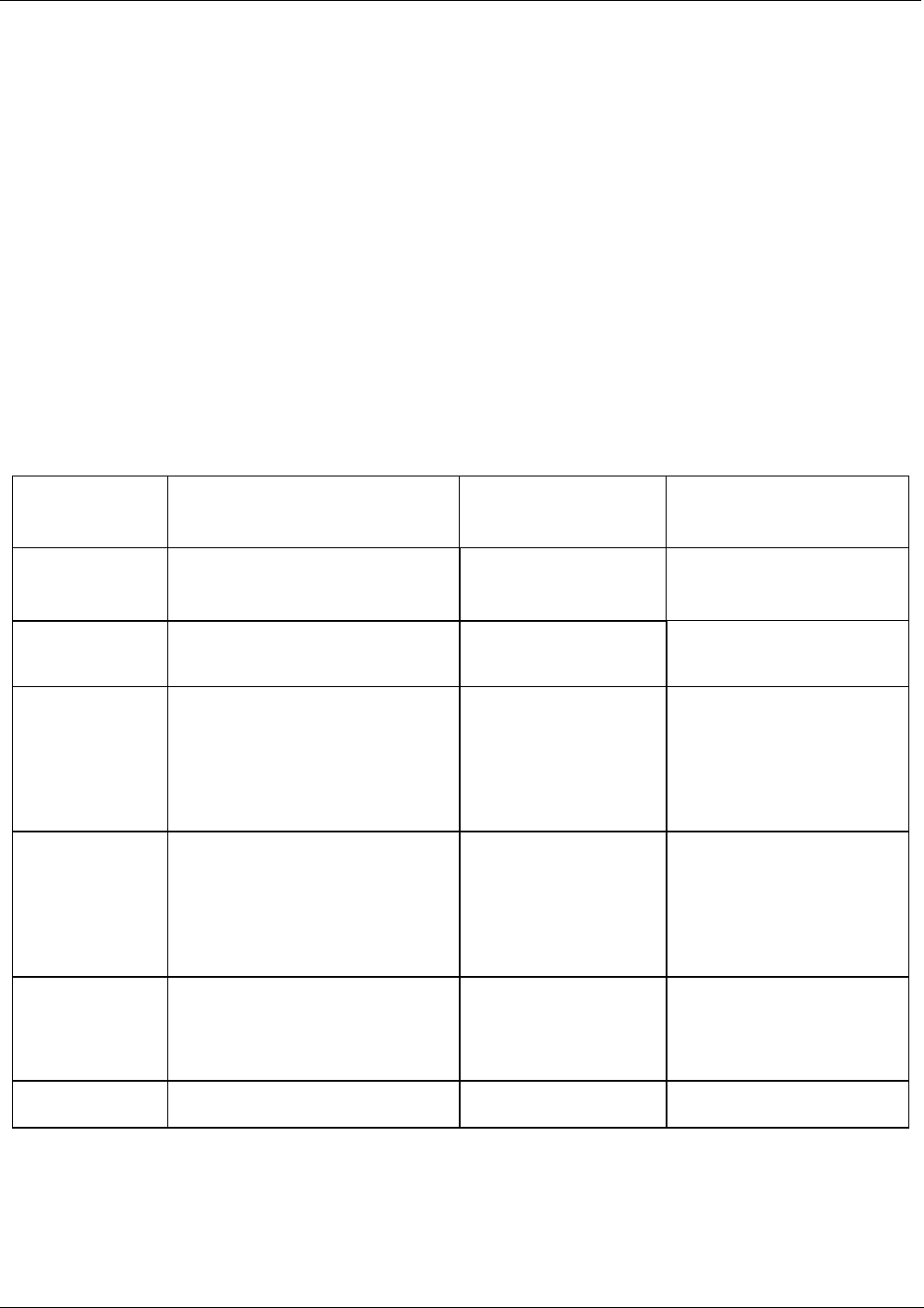

Table 10-1: Daily Activity Matrix

CHARACTERISTI

C

ACCEPTANCE LIMITS

FREQUENCY AND

METHOD OF

MEASUREMENT

ACTION IF

REQUIREMENTS ARE NOT

MET

Shelter

Temperature

Mean temperature between 22C

and 28C (72F and 82F), daily

fluctuations not greater than 2C.

Check thermograph chart

daily for variations not

greater than 2C (4F).

Mark strip chart for the

affected time period.

Repair/adjust temp control.

Sample

Introduction

System

No moisture, foreign material, leaks,

obstructions; sample line connected

to manifold.

Weekly visual inspection.

Clean, repair or replace as

needed.

Recorder

Adequate ink supply and chart

paper.

Legible ink traces.

Correct settings of chart speed and

range switches.

Correct time.

Weekly visual inspection.

Replenish and chart paper

supply

Adjust recorder time to agree

with clock note on chart.

Analyzer

Operational

Settings

Flow and regulator indicators at

proper settings.

Temperate indicators cycling or at

proper levels.

Analyzer in sample mode.

Zero/span controls locked.

Weekly visual inspection. Adjust or repair as needed.

Analyzer

Operational

Check

Zero and span within tolerance limits

as described in Subsec. 9.1.3 of

Sec. 2.0.9

(Ref. 11).

Level 1 zero and span

every 2 weeks; Level 2

between Level 1 checks

at frequency desired by

user.

Isolate source error, and

repair.

After corrective action,

recalibrate analyzer.

Precision Check

Assess precision as described in

Sec. 2.0.8 (Ref. 11).

Every 2 weeks,

Sec. 2.0.8 (Ref. 11).

Calculate, report precision,

Sec. 2.0.8 (Ref. 11).

06870C DCN6332