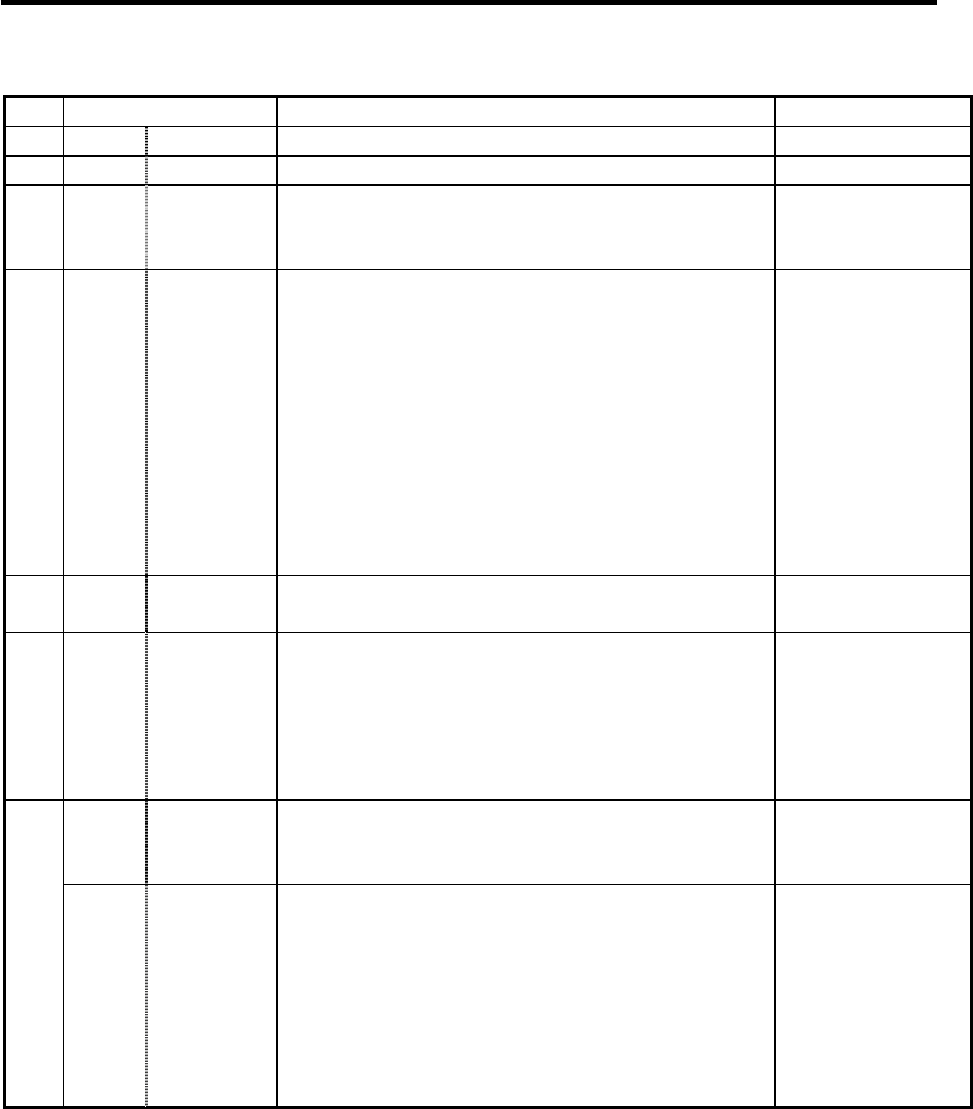

5. Base Specifications Parameters

52

# Items Details

Setting range (unit)

1234 set06

Not used.

1235 set07 Not used.

1236 set08

(bit0)

Manual

rotation axis

feedrate unit

Select the unit of manual rotation axis feedrate.

0: Fixed to [°/min]

1: Same speed as before

0/1

1237

(PR)

set09

(bit0)

External

workpiece

offset

Set up this function to use the external workpiece

coordinates by shifting them to the Z axis.

0: Does not reverse the sign of external workpiece

offsets (Z shift) (same as before).

1: Reverses the sign of external workpiece offsets (Z

shift).

(Note) When the sign of external workpiece offsets (Z

shift) has been reversed, do not measure those

external workpiece offsets. However, the

external workpiece offsets can be measured by

tool pre-setter.

0/1

1238

(PR)

set10 Not used.

1239

(PR)

set11

(bit0)

Coil

switching

method

0: Via PLC. (YD3F)

1: NC internal processing. (YD3F is invalid.)

(Note) As for C6/C64/C64T, always set “1” when

using MDS-B-SP and later. However, if the

system structure needs the mechanical gears

for spindles, set “0”.

0/1

1240

(PR)

set12

(bit0)

Handle input

pulse

Select the handle input pulse.

0: MELDAS standard handle pulse

1: Handle 400 pulse

0/1

set12

(bit1)

Megatorque

motor handle

feed magnifi-

cation

Select the magnification of megatorque motor handle 1

pulse.

0: Double the handle 1 pulse magnification

specified by the handle feed magnification signal

(Y780, Y781, Y782).

1: Use the handle 1 pulse magnification specified by

the handle feed magnification signal (Y780,

Y781, Y782) as is.

0/1