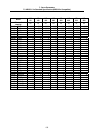

7. Servo Parameters

7.3 MDS-C1-Vx Standard Specification (MDS-B-Vx Compatible)

150

No. Items Details Setting range

2246 SV046 Not used. Set to “0”. 0

2247 SV047

EC

Inductive

voltage

compensation

gain

Set the inductive voltage compensation gain. Set to

“100” as a standard.

If the current FB peak exceeds the current command

peak, lower the gain.

0 to 200

(%)

2248 SV048

EMGrt

Vertical axis

drop prevention

time

Input a length of time to prevent the vertical axis from

dropping by delaying Ready OFF until the brake

works when the emergency stop occurs.

Increase the setting by 100ms at a time and set the

value where the axis does not drop.

0 to 20000

(ms)

2249 SV049

PGN1sp

Position loop

gain 1 in

spindle

synchronous

control

Set the position loop gain during the spindle

synchronous control (synchronous tapping,

synchronous control with spindle/C axis).

Set the same value as the value of the spindle

parameter, position loop gain in synchronous

control.

When performing the SHG control, set this with

SV050 (PGN2sp) and SV058 (SHGCsp).

1 to 200

(rad/s)

2250 PGN2sp Position loop

gain 2 in

spindle

synchronous

control

Set this with SV049 (PGN1sp) and SV058

(SHGCsp) if you wish to perform the SHG control in

the spindle synchronous control (synchronous

tapping, synchronous control with spindle/C axis).

When not performing the SHG control, set to “0”.

0 to 999

(rad/s)

2251 SV051

DFBT

Dual feed back

control time

constant

Set the control time constant in dual feed back.

When “0” is set, the actual value that is set is 1ms.

The higher the time constant is, the closer it gets to

the semi-closed control, so the limit of the position

loop gain is raised.

0 to 9999

(ms)

2252 SV052

DFBN

Dual feedback

control

non-sensitive

band

Set the non-sensitive band in the dual feedback

control.

Set to “0” as a standard.

0 to 9999

(µm)

2253 SV053

OD3

Excessive error

detection width

in special

control

Set the excessive error detection width when servo

ON in a special control (initial absolute position

setting, stopper control, etc.).

If “0” is set, excessive error detection won’t be

performed when servo ON during a special control.

0 to 32767

(mm)

2254 SV054

ORE

Overrun

detection width

in closed loop

control

Set the overrun detection width in the full-closed loop

control.

If the gap between the motor end detector and the

linear scale (machine end detector) exceeds the

value set by this parameter, it is judged to be overrun

and Alarm 43 will be detected.

When “-1” is set, the alarm detection won’t be

performed. When “0” is set, overrun is detected with

a 2mm width.

-1 to 32767

(mm)