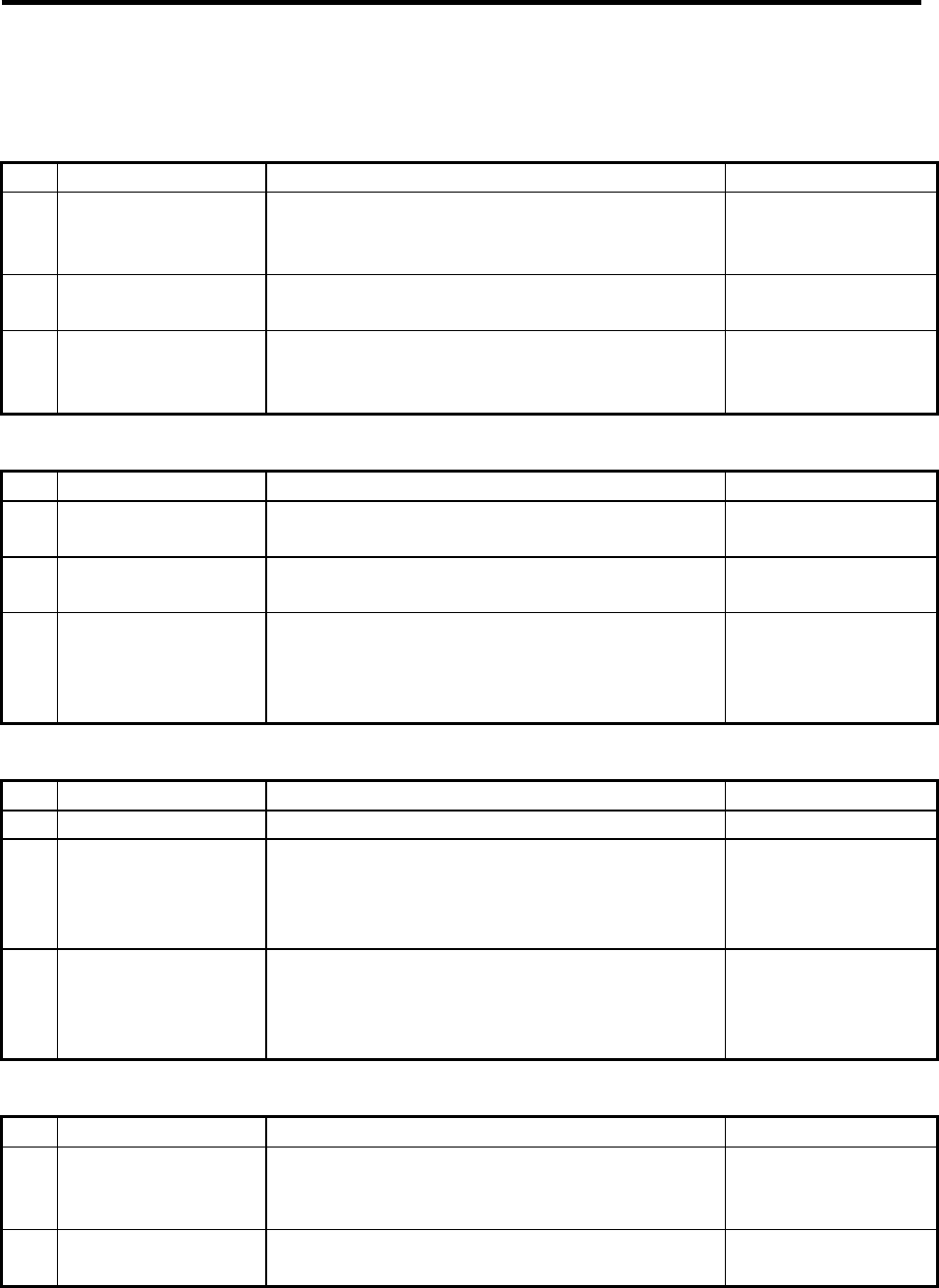

2. Machining Parameters

2.2 Process Parameters

4

2.2 Process Parameters

<WRK COUNT> (No. of workpieces machined)

# Item Contents Setting range (unit)

8001 WRK COUNT M Set the M code that counts the No. of workpiece

repeated machining.

The No. will not be counted when set to 0.

0 to 99

8002 WRK COUNT The current machining No. is displayed. Set the

initial value.

0 to 999999

8003 WRK LIMIT Set the maximum No. of workpieces machined.

A signal is output to PLC when the No. of machining

times is counted to this limit.

0 to 999999

<AUTO TLM> (Automatic tool length measurement)

# Item Contents Setting range (unit)

8004 SPEED Set the feedrate during automatic tool length

measurement.

1 to 1000000

(mm/min)

8005 ZONE r Set the distance between the measurement position

and deceleration start point.

0 to 99999.999 (mm)

8006 ZONE d Set the tolerable zone of the measurement position.

If the sensor signal turns on in front of d before the

measurement position‚ or if the signal does not turn

on after d is passed‚ an alarm will occur.

0 to 99999.999 (mm)

<AUTO CORNER OVR> (Automatic corner override)

# Item Contents Setting range (unit)

8007 OVERRIDE Set the override value for automatic corner override. 0 to 100 (%)

8008 MAX ANGLE Set the max. corner opening angle where deceler-

ation should start automatically.

If the angle is larger than this value‚ deceleration will

not start.

0 to 180 (degrees)

8009 DSC. ZONE Set the position where deceleration starts at the

corner.

Designate at which length point before the corner

deceleration should start.

0 to 99999.999 (mm)

<T-TIP OFFSET> (Wear data input)

# Item Contents Setting range (unit)

8010 ABS. MAX.

(For L system only)

Set the max. value when inputting the tool wear

compensation amount.

A value exceeding this setting value cannot be set.

0 to 99.999 (mm)

8011 INC. MAX.

(For L system only)

Set the max. value for when inputting the tool wear

offset amount in the addition mode.

0 to 99.999 (mm)