Section 1

General Information

5-16 Troubleshooting MN722

Electrical Noise Considerations Continued

Special Drive Situations

For severe noise situations, it may be necessary to reduce transient voltages in the wires

to the motor by adding load reactors. Load reactors are installed between the control and

motor.

Reactors are typically 3% reactance and are designed for the frequencies encountered in

PWM drives. For maximum benefit, the reactors should be mounted in the drive

enclosure with short leads between the control and the reactors. Baldor can deliver line

and load reactors that will reduce ripple current and improve motor life.

Control Enclosures Motor controls mounted in a grounded enclosure should also be connected to earth

ground with a separate conductor to ensure best ground connection. Often grounding

the control to the grounded metallic enclosure is not sufficient. Usually painted surfaces

and seals prevent solid metallic contact between the control and the panel enclosure.

Likewise, conduit should never be used as a ground conductor for motor power wires or

signal conductors.

Special Motor Considerations

Motor frames must also be grounded. As with control enclosures, motors must be

grounded directly to the control and plant ground with as short a ground wire as possible.

Capacitive coupling within the motor windings produces transient voltages between the

motor frame and ground. The severity of these voltages increases with the length of the

ground wire. Installations with the motor and control mounted on a common frame, and

with heavy ground wires less than 10 ft. long, rarely have a problem caused by these

motor–generated transient voltages.

Sometimes motor frame transient voltages are capacitively coupled to feedback devices

mounted on the motor shaft. To prevent this problem, add electrical isolation between

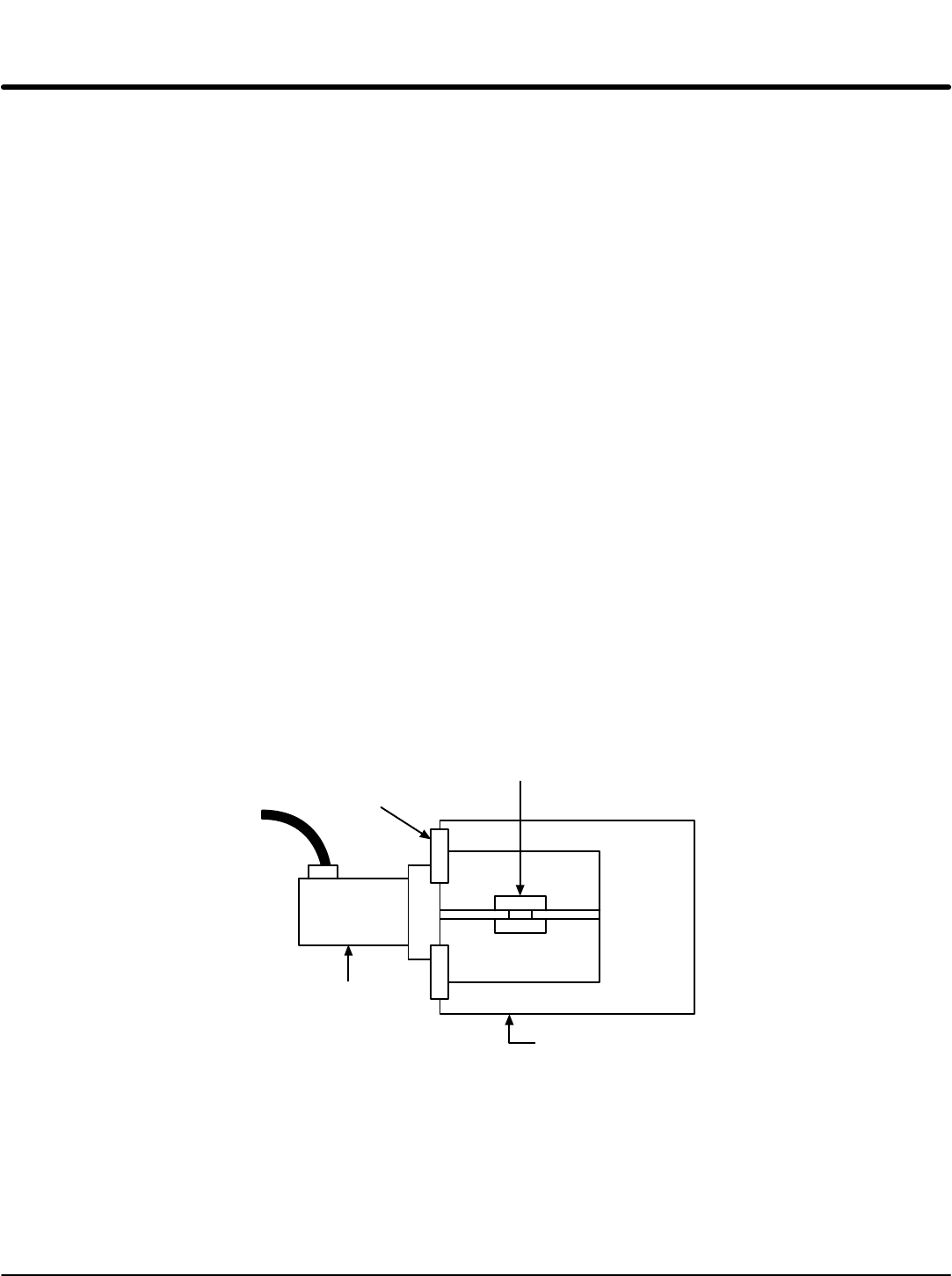

the motor and the feedback device. The most simple isolation method, shown in Figure

5-2, has two parts: 1) A plate of electrical insulating material placed between the motor

mounting surface and the feedback device. 2) An insulating coupling between motor

shaft and the shaft of the feedback device.

Figure 5-2 Isolated Mounting Method

Insulating plate

Insulating Coupling

Encoder or other

feedback device

Mounting bracket