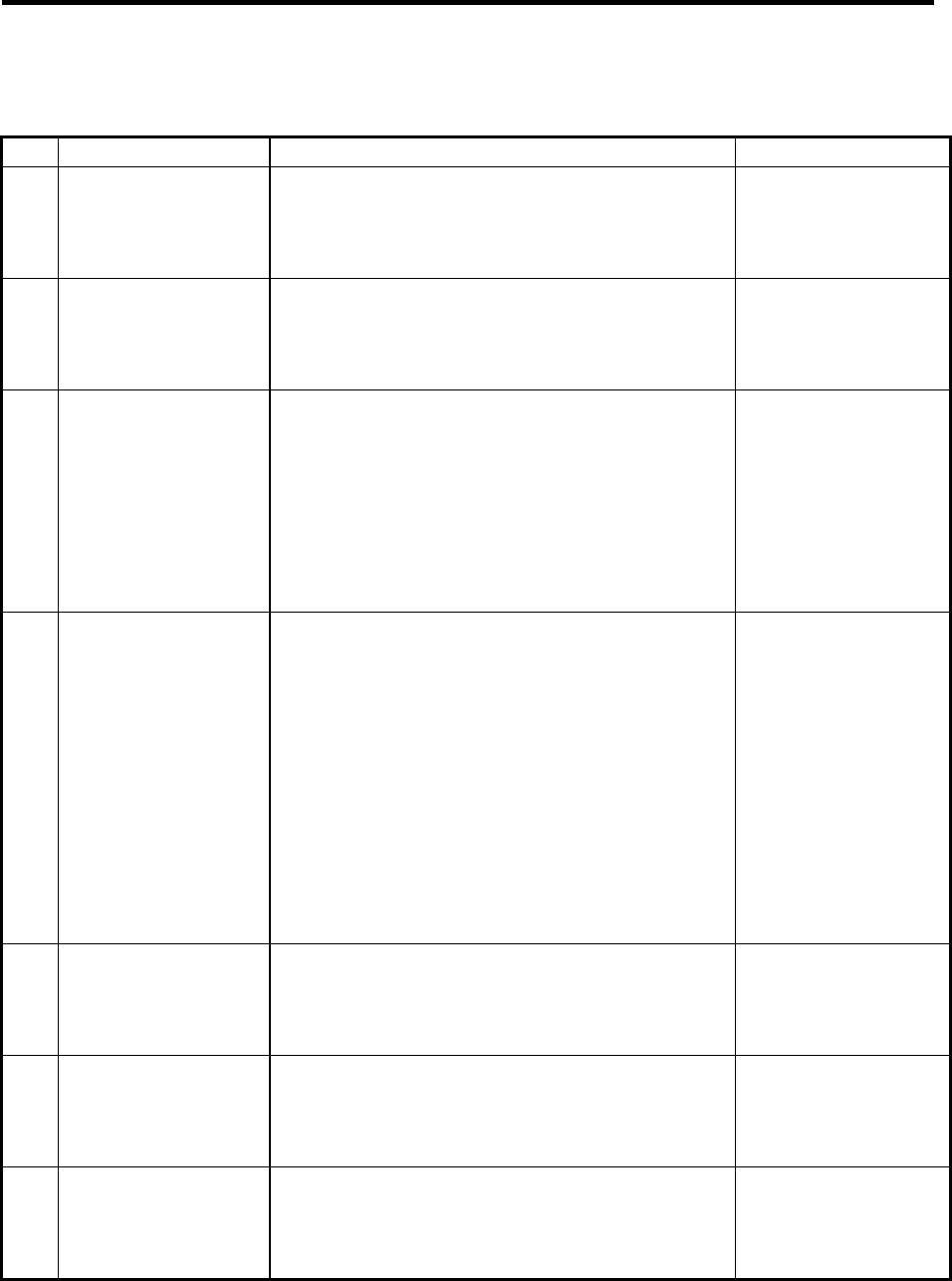

2. Machining Parameters

2.4 Axis Parameters

7

2.4 Axis Parameters

# Item Contents Setting range (unit)

8201 AX. RELEASE Select the function to remove the control axis from

the control target.

0: Control as normal

1: Remove from control target

0/1

8202 OT-CHECK OFF Select the stored stroke limit function set in #8204

and #8205.

0: Stored stroke limit valid

1: Stored stroke limit invalid

0/1

8203 OT-CHECK-CANCEL When the simple absolute position method ("#2049

type" is 9) is selected‚ the stored stroke limits I, II (or

IIB) and IB will be invalid until the first reference

point return is executed after the power is turned on.

0: Stored stroke limit II valid (according to #8202)

1: Stored stroke limit II invalid

(Note) This setting (#8203) affects all the stored

stroke limits.

0/1

8204 OT-CHECK-N Set the coordinates of the (–) direction in the

moveable range of the stored stroke limit II or the

lower limit coordinates of the prohibited range of

stored stroke limit IIB.

If the sign and value are the same as #8205 (other

than "0"), the stored stroke limit II (or IIB) will be

invalid.

If the stored stroke limit IIB function is selected, the

prohibited range will be between two points even

when #8204 and #8205 are set in reverse.

When II is selected, the entire range will be

prohibited.

–99999.999 to

+99999.999 (mm)

8205 OT-CHECK-P Set the coordinates of the (+) direction in the

moveable range of the stored stroke limit II or the

upper limit coordinates of the prohibited range of

stored stroke limit IIB.

–99999.999 to

+99999.999 (mm)

8206 TOOL CHG. P Set the coordinates of the tool change position for

G30. n (tool change position return).

Set with coordinates in the basic machine coordinate

system.

–99999.999 to

+99999.999 (mm)

8207 G76/87 IGNR

(For M system only)

Select the shift operation at G76 (fine boring) and

G87 (back boring).

0: Shift effective

1: No shift

0/1