Teledyne API Model 200AU NO

X

Analyzer Instruction Manual, 02293, Rev. F

7-11

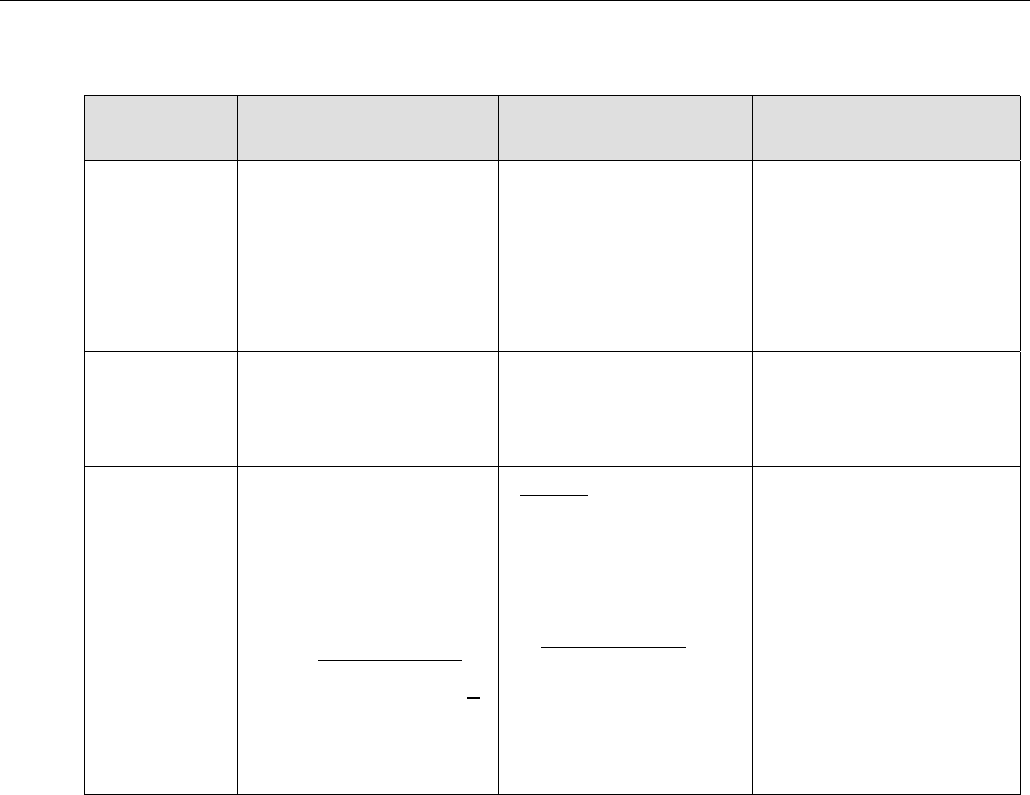

Table 7-10: Activity Matrix for Calibration Procedure

Equipment/

Supplies

Acceptance Limits

Frequency And Method

Of Measurement

Action If Requirements

Are Not Met

Calibration

gases

Sec. 2.0.7, Subsec. 7.1

(Q.A. Handbook)

Assayed against an

NIST-SRM quarterly,

Sec. 2.0.7, (Q.A.

Handbook)

Working gas standard is

unstable, and/or

measurement method is

out of control; take

corrective action such as

obtaining new calibration

gas.

Dilution gas Zero air, free of

contaminants; TAD

2

and

Sec. 2.0.7, Subsec. 7.1

(Q.A. Handbook)

See TAD

2

Return to supplier or take

appropriate action with

generation system

Multi-point

calibration

(GPT)

1. t

R

< 2 minutes P

R

>

2.75 ppm/min

2. Use calibration

procedure in

Subsection 2.4 (Q.A.

Handbook); also TAD

2

and Federal Register

3. Converter efficiency >

96%

Method

1. Sect. 7.6.4 (this

manual)

2. Section 7.6.5.3 (this

manual), TAD

2

,

Federal Register

and

Figure 7-2; see

Section 7.6.7 for

frequency

3. Subsection 7.6.6 (this

manual)

1. Adjust flow conditions

and/or reaction chamber

volume to meet

suggested limits

2. Repeat the calibration

3. Replace or service the

converter

7.6.2 Calibration Gas and Zero Air Sources

Production of Zero Air

Due to the high sensitivity of the M200AU special care must be taken to assure that the zero air

has extremely low levels of pollutants. We recommend using Ultra Zero Air, which is commonly

used for gas chromatographic applications. If other zero air sources are used, the NO

concentration should be < 1 ppt (0.001 ppb) and the concentration of interferent gasses should be

< 1 ppt (0.001 ppb) for the sum total of all interferents.

Devices that condition ambient air by drying and removal of pollutants are available on the

commercial market such as the Teledyne API Model 701 Zero Air Module. We recommend this

type of device for generating zero air. Detailed procedures for generating zero air are in TAD

2

.