Teledyne API Model 200AU NO

X

Analyzer Instruction Manual, 02293, Rev. F

9-53

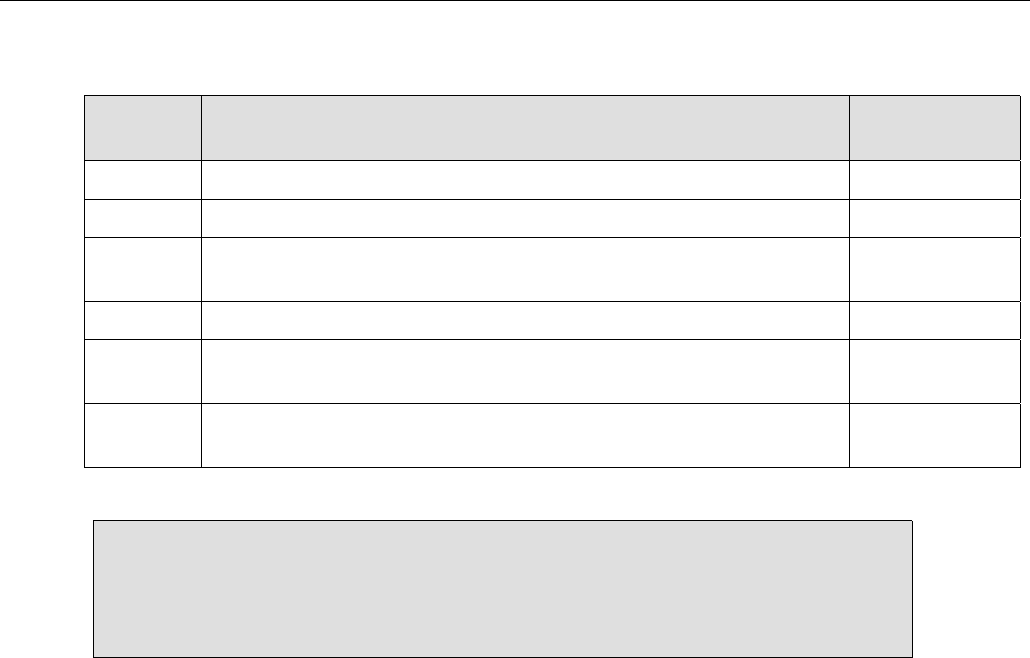

Table 9-11: Ozone Generator Control Conditions

Condition Description

Ozone

Generator

1

Manual override off (SETUP-MORE-DIAG-OZONE GEN).

OFF

2 Manual override on. ON

3 Ozone flow below low warning limit for 5 minutes (OFLOW_SET

setup variable, typically <40 cc/min).

OFF

4 Instrument powered on for more than 30 minutes. ON

5 Instrument powered off for less than 1 hour and ozone generator was

on when instrument was powered off.

ON

6 Ozone flow above low warning limit for 0.5 minutes and condition 4

or 5 is true.

ON

NOTE

The ozone generator is independently controlled in the SIGNAL I/O, OPTIC

TEST, and ELECTRICAL TEST diagnostics. After exiting these diagnostics,

the ozone generator is restored to the state specified by the above conditions.

9.3.6.1 PermaPure Drier

The PermaPure drier is constructed of 2 concentric tubes. The inner tube is a special material

that has an affinity for water vapor. The outer annulus is evacuated by the instrument pump. This

creates a concentration gradient causing water in ambient air to diffuse into the outer annulus,

thus the air in the inner tube becomes progressively drier as it progresses down the tube.

Due to the large number of connections and fittings on the drier, the most common drier fault is

leaks. Before proceding with any other procedures check the drier for leaks.

Occasionally the drier gets contaminated. The manufacturer of the drier recommends replacing

the drier rather than trying to clean it. If cleaning is chosen, the following options are available:

1. Dirt - Clean any solids from dryer inlet by brushing. Use clean dry air to blow any loose

particles from the inlet. Deionized water or dilute(5-10% conc HCl in deionized water)

hydrochloric acid can be passed through the dryer. This should be done only with the dryer

and HCl at room temperature.

2. Organic liquids and freons - Rinse the inner and outer tubes using 1,1,1 trichlorethane.

Follow the solvent with dry air to purge the solvent.

3. Inorganic salts and oxgenated hydrocarbons can be removed by rinsing with 10% nitric

acid at 50

°

C.