3 - 1 3 - 1

MELSOFT

3. FUNCTION LIST

3. FUNCTION LIST

3.1 Function List

(1) Function list

GX Configurator-AP functions are listed below mode-by-mode.

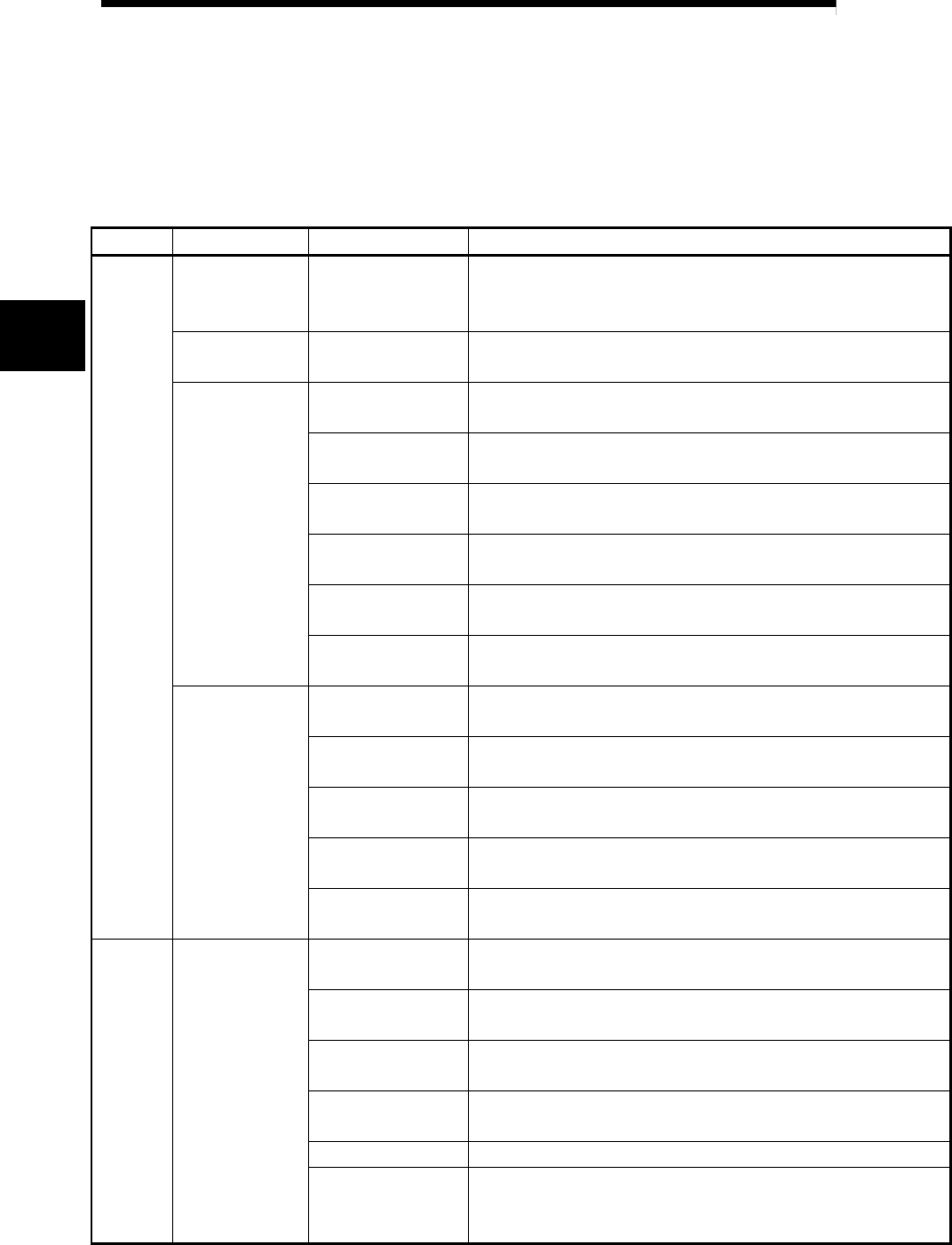

Mode Main Screen Function Description

Parameter Parameter setting

Set the basic parameters1, basic parameters2, extended

parameters1, extended parameters2, OPR basic parameters and

OPR extended parameters on an axis basis.

Servo parameter

(AD75M only)

Servo parameter

setting

Set the servo basic parameters, servo adjustment parameters and

servo extension parameters on an axis basis.

Positioning data

setting

Set the positioning data, such as pattern, control method,

accel/decel time and address, on an axis basis.

Positioning data

monitor

Monitor the positioning data during execution on an axis basis.

Positioning data test

Perform test operation of positioning control on an axis or

positioning data basis.

Teaching

Set the feed address of the moved axis to the address of

positioning data by JOG operation or the like.

M code comment

setting

Set comments to the M codes assigned to the positioning data on

an axis basis.

Positioning data

axis #1

Positioning data

axis #2

Positioning data

axis #3

Offline simulation

Assume axis operation from the set positioning data on an axis

basis.

Start block data

setting

Set the starting mode, etc. of the positioning data specified for

points on an axis basis.

Start block data

monitor

Monitor the point at which positioning control is being executed on

an axis basis.

Start block data test

Perform test operation of positioning control from the point of the

specified block on an axis basis.

Condition data

setting

Set the data which is used as the starting condition of the start

block data on an axis basis.

Edit

Start block axis

#1

Start block axis

#2

Start block axis

#3

Indirect data setting

Set the positioning data numbers set to the indirect designating

buffer memory of the AD75 on an axis basis.

Operation monitor

(main screen)

Monitor the operating states, such as addresses, axis speeds, axis

statuses and executed positioning data numbers, of all axes.

History monitor

Monitor the error, warning, start or error-time start history of all

axes.

Signal monitor

Monitor the X/Y devices, external signals or status signals of all

axes.

Operation monitor

(dialog)

Monitor the control states, AD75 parameter settings or others of all

axes.

Servo monitor Monitor the servo amplifier and servomotor states of all axes.

Monitor

Operation

monitor (test)

Operation test

Test the positioning data number-specified start, current value

change, speed change, original position return, JOG operation and

manual pulse generator operation of all axes.

3