4 - 81

ENG

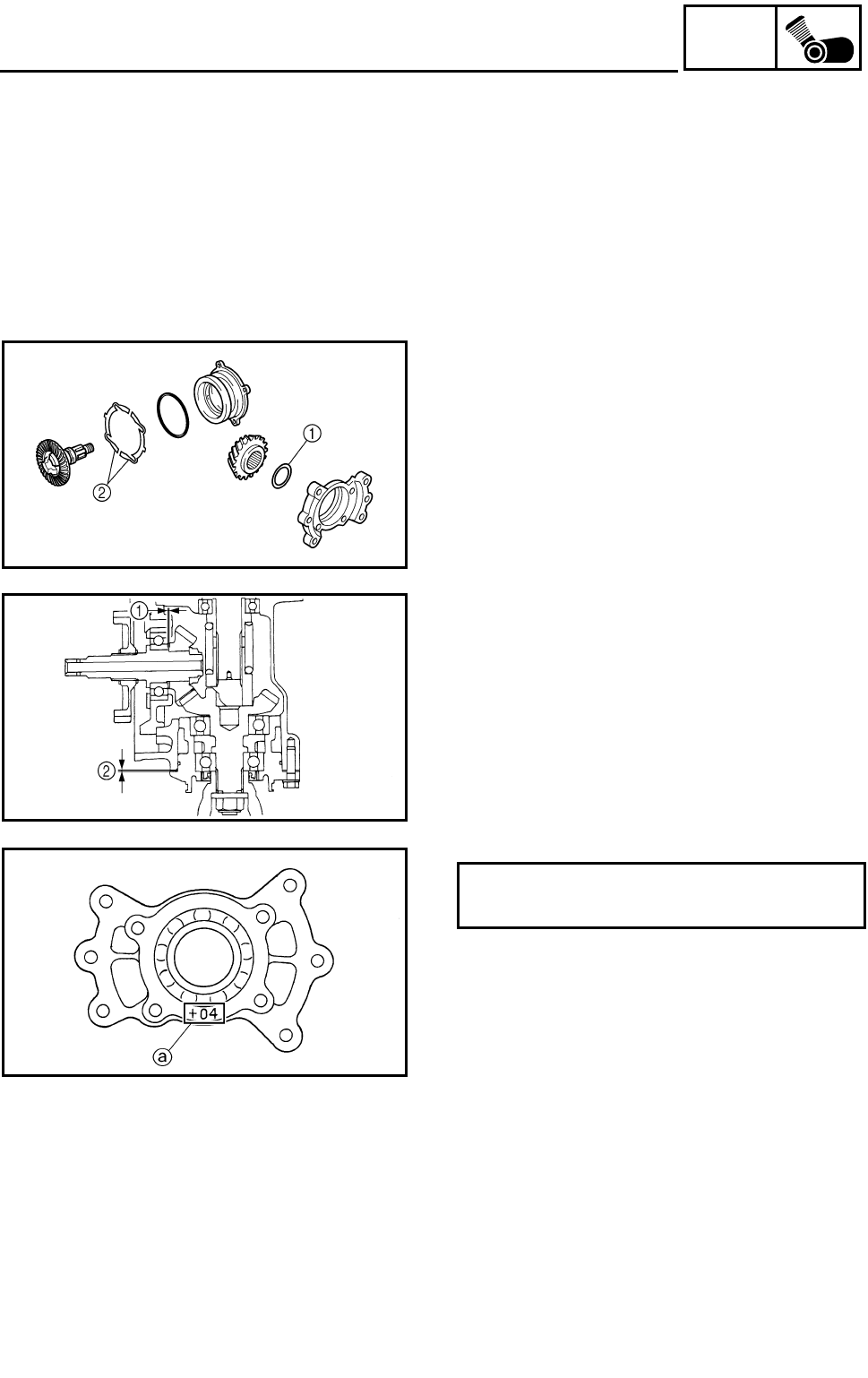

MIDDLE GEAR

4.Check:

●

O-ring

Damage → Replace.

●

Bearings

Pitting/damage → Replace.

5.Check:

●

U-joint movement

Roughness → Replace U-joint.

SELECTING THE MIDDLE DRIVE AND

DRIVEN GEAR SHIMS

When the drive and driven gear, bearing

housing assembly and/or crankcase are

replaced, be sure to adjust the gear shims.

1.Select:

●

Middle drive gear shim 1

●

Middle driven gear shim 2

*****************************************************

Selection steps:

●

Position middle drive and driven gear by

using shims 1 and 2 with their respective

thickness calculated from information

marked on crankcase, bearing housing and

drive gear end.

1

Shim thickness “A”

2

Shim thickness “B”

●

To find shim thickness “A”, use following

formula:

Where:

a = a numeral (usually a decimal number)

on the bearing housing is either added

to or subtracted from “10.5”.

b = drive pinion gear to driven pinion gear

center distance (considered constant

“55”).

c = a numeral (usually a decimal number)

on the right crankcase specifies a

thickness of “66”.

Middle drive pinion gear shim thickness:

“A” =

c

–

a

–

b