4 - 30

ENG

CYLINDER AND PISTON

3rd step:

●

Find the piston-to-cylinder clearance with the

following formula.

●

If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

*****************************************************

Piston-to-cylinder clearance =

Cylinder bore “C” –

Piston skirt diameter “P”

Piston-to-cylinder clearance:

0.040 ~ 0.065 mm

(0.0016 ~ 0.0026 in)

<Limit>: 0.150 mm (0.0059 in)

CHECKING THE PISTON RINGS

1.Measure:

●

Piston ring side clearance

Use a feeler gauge.

Out of specification → Replace the piston

and rings as a set.

N

OTE:

Clean carbon from the piston ring grooves and

rings before measuring the side clearance.

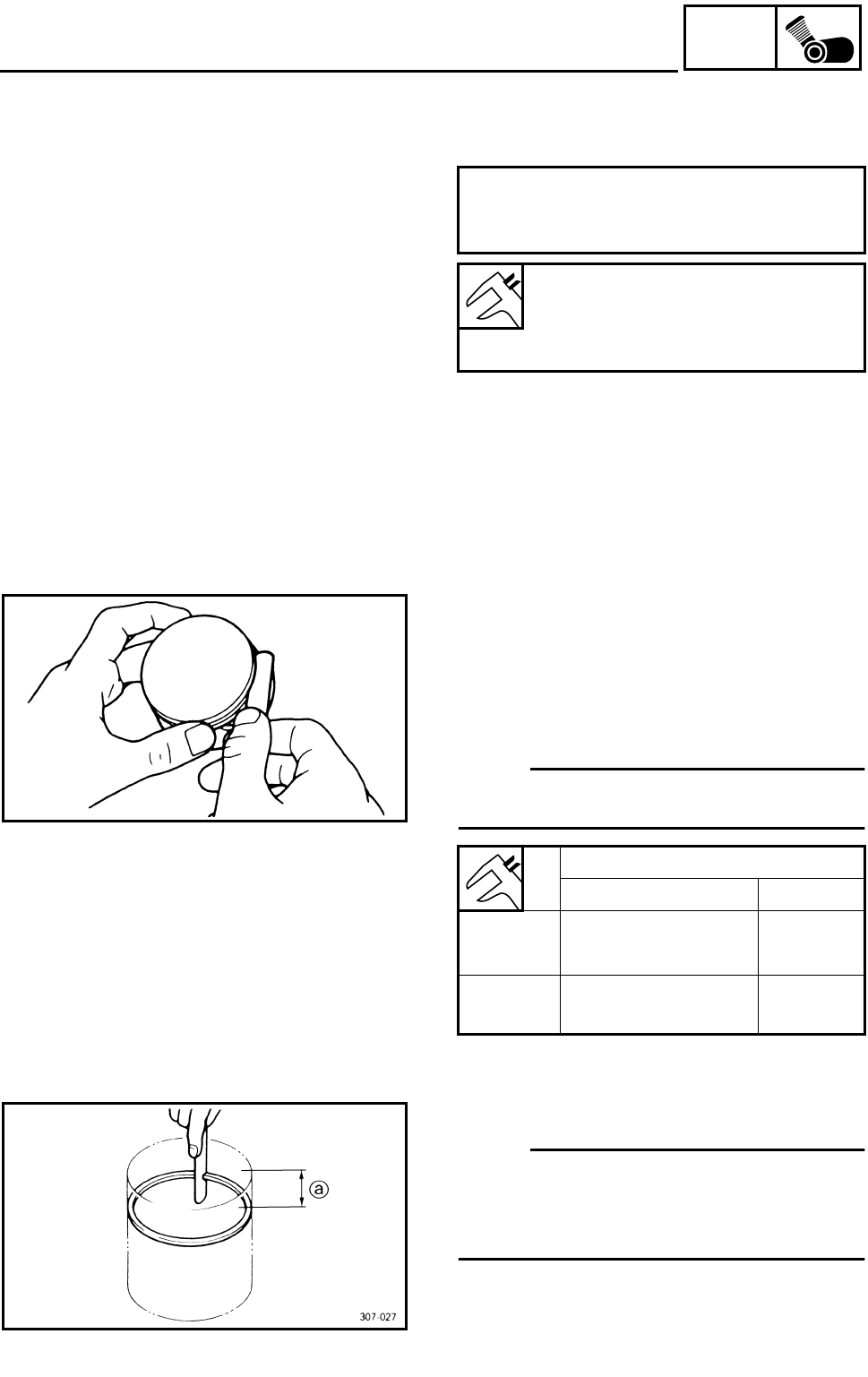

2.Position:

●

Piston ring

(in cylinder)

N

OTE:

Insert a ring into the cylinder and push it

approximately 40 mm (1.6 in) into the cylinder.

Push the ring with the piston crown so that the

ring will be at a right angle to the cylinder bore.

a

40 mm (1.6 in)

Side clearance

Standard Limit

Top

ring

0.03 ~ 0.08 mm

(0.0012 ~ 0.0031 in)

0.13 mm

(0.0051 in)

2nd

ring

0.03 ~ 0.07 mm

(0.0012 ~ 0.0028 in)

0.13 mm

(0.0051 in)