4

TO REDUCE THE RISK OF SEVERE

INJURY OR DEATH: READ AND FOLLOW

ALL INSTALLATION INSTRUCTIONS AND

GATE SYSTEM DESIGN PARAMETERS!

WARNING!

GATE SYSTEM DESIGN AND INSTALLATION

SAFETY CHECK LIST:

• The GS4000 operator may be installed on a Class I, II, III, or IV

Vehicular Swing Gate. See page 3 for an explanation of the

different Class locations. See the last page of this manual for the

operator specifications (voltage, maximum gate weight & length

etc.).

• Make sure that the gate moves freely, all hinges are in good

working order, the gate does not bind in any manner and the gate

swing area is clean and free of irregularities. DO NOT

INSTALL THE OPERATOR UNTIL ALL GATE PROBLEMS

HAVE BEEN CORRECTED.

• Do not increase the built-in overload detector adjustment or

overtighten the torque limiter to compensate for a poorly

working gate. A well maintained gate will ensure easy manual

operation (if needed) and maximum operator obstruction

sensitivity.

• Install the operator on the inside of the property/fence line. DO

NOT install an operator on the public side of the fence line or

gate. Outward swinging gates should not open into public areas.

• The gate must be installed in a location so that enough clearance

is supplied between the gate and any adjacent structures when

opening and closing to reduce the risk of entrapment.

• Make sure the gate operating system is placed far enough back

from the road to eliminate traffic backup. The distance from the

road, size of the gate, usage level and gate cycle/speed must be

taken into consideration to eliminate potential hazards.

• For ORNAMENTAL “GRILL TYPE” GATES (or any other

type of open gate where a handhold or toehold may be achieved),

injuries may occur when people put arms through the openings or

children “ride” the gate by standing on the bars and holding on to

the gate. THIS POTENTIAL HAZARD CAN BE MINIMIZED

BY INSTALLING A MESH SCREEN ON THE GATE. Allstar

strongly recommends the entire gate and adjacent fence area the

gate covers when open be meshed or guarded such that a

handhold or toehold cannot be achieved. See Figure 2.

• All Allstar gate operators are VEHICULAR GATE

OPERATORS and as such are NOT RECOMMENDED FOR

PEDESTRIAN traffic. In installations where pedestrians are

likely to be nearby, install a pedestrian gate and use leading

edge detectors and/or photocells in your design to protect system

entrapment zones. Allstar can provide these products for

incorporation in your design.

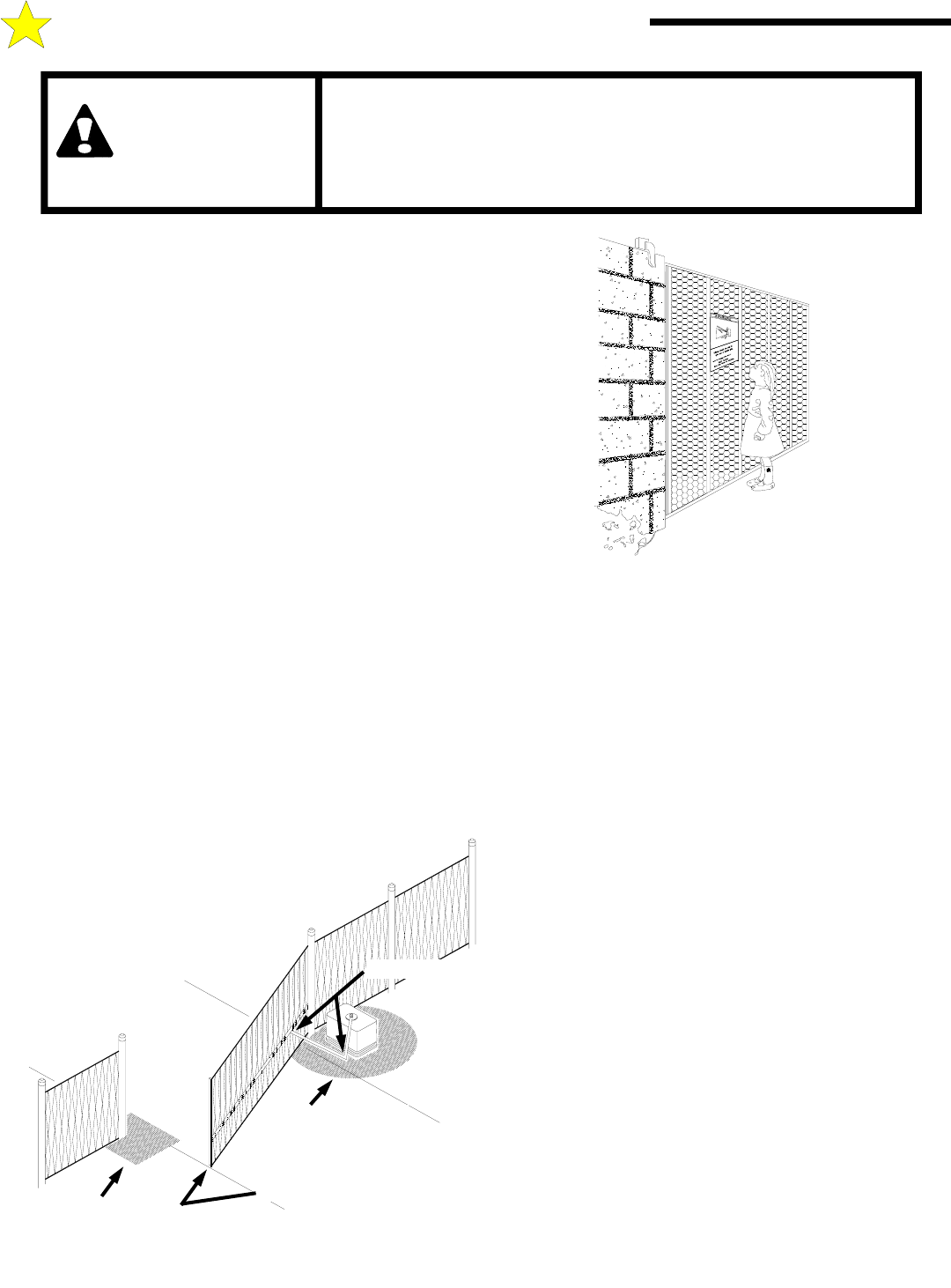

• Use the illustration at left (Figure 3) to minimize the risk of

injury in your design of the swing gate operator system.

IDENTIFY THE ENTRAPMENT ZONES AND PINCH

POINT AREAS IN YOUR GATE. Design the gate installation

to minimize the risk of entrapment in these areas. Install

additional safety equipment such as four wire edges and

photocells to further minimize risk. All entrapment zones are

required to be protected.

• Entrapment Zones: Design in personal entrapment protection

devices to protect people from entrapment in the zones shown in

Figure 3 at left.

• Pinch Points: Use protective measures (guards, padded edges,

etc.) to protect people from the pinch points shown in Figure 3 at

left.

• SWING GATES HAVE THE POTENTIAL HAZARD OF

HANDS AND FINGERS BEING PINCHED between the gate

edge and the post to which the gate is mounted. It is

recommended that the hinges be mounted so that this opening

Figure 2

104949

A: GATE SYSTEM DESIGN/ INSTALLATION

PINCH POINTS

ELECTRIC GATE EDGE

ENTRAPMENT

ZONE

ENTRAPMENT

ZONE

104932

Figure 3