13

C: INSTALLING THE OPERATOR

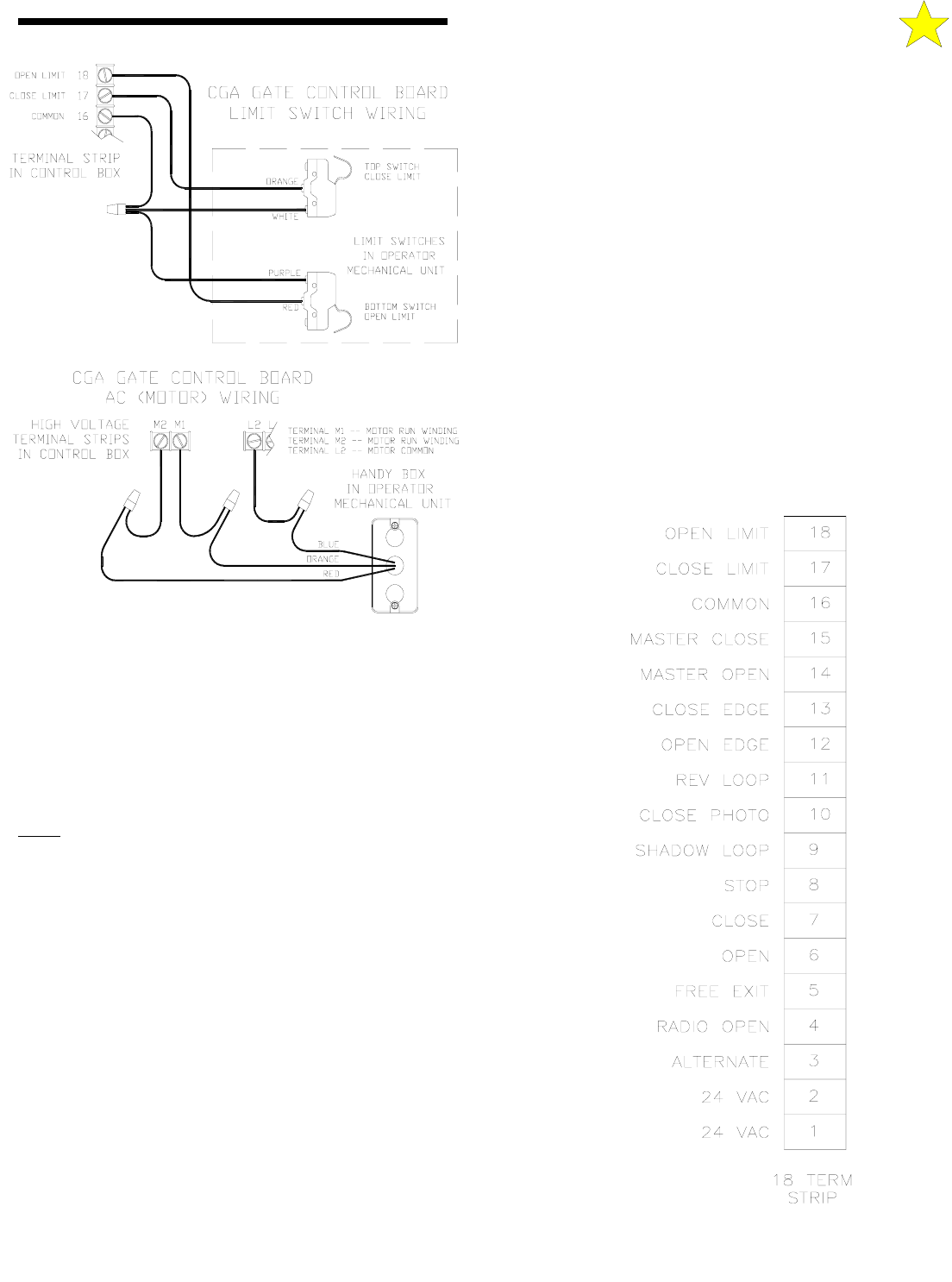

Figure 13: GS4000 Limit & Motor Wiring Diagram

110093

contact is closed. Now, a contact will be made to the limit switch

input at the terminal board through both limit switch contacts. Both

motors will be turned off.

A wiring schematic of the Bi-Parting installation is shown in Figure

15, page 14. It is important this schematic be followed closely and

that the color codes at the MECHANICAL UNITS and the

CONTROL BOX be followed exactly. Most of the difficulties

encountered with Bi-Parting installations are due to the wiring

instructions not being followed.

ACCESSORY EQUIPMENT HOOK-UP

All accessory equipment is connected to the 18 terminal barrier strip

located inside the GS4000 Control Box. To expose this terminal

strip, remove the cover on the Control Box.

There are 13 command inputs (#3 through #15) available to the

installer on the GS4000 in a addition to a common terminal (#16).

To trigger any of these inputs, a switch or relay closure to the

common terminal for a duration longer than 100 milliseconds and of

a resistance of less than 100 ohms is necessary. Eight of the inputs,

FREE EXIT (#5), OPEN (#6), STOP (#8), REV LOOP (#11),

BI-PARTING WIRING

For a Bi-Parting installation, an additional two conduits must be

installed between the First Mechanical Unit and the Second Mechanical

Unit. (See Figure 8, page 8.) For a Bi-Parting installation, one operator

must be a Left Hand unit and the other a Right Hand unit.

The two motors of the Bi-Parting GS4000's will be wired in parallel.

BOTH

motors will run until both are shut off. If the two gate leafs do

not open exactly the same amount, then the first gate leaf to reach it's

open position will have to be held (or mechanically stopped) in that

position until the second gate reaches its open position. Now, both

motors can be turned off. The stop for the first gate can be installed

externally or the GS4000 internal Stop Pall mounted on the large output

drive sprocket of the GS4000 may be used.

The Limit Switch contacts of the two Bi-Parting units need to be wired

in series. Both limit switch contacts must be closed before a connection

is made to the limit switch input at the Control Box to stop the motors at

the Open or Closed position.

The operation of the Bi-Parting installation is as follows: After receipt

of a command to open, both units will begin to open together. The first

gate to reach its open position will be stopped by the mechanical

stop. Its motor will continue to run. The Torque Limiter will be

adjusted to slip when the stop is encountered with the motor still

running. The limit switch contact on this first unit is adjusted to

close at this position. The second gate has not reached its fully

open position. Its limit switch will be still open and no command

will be given to the limit switch input at the terminal board until the

gate has reached the maximum open position and the open limit

Figure 14: Terminal Strip