10

HARDWARE

LEGEND

1

(1 EA) 1/2-13 X 2”

BOLT & 1/2 FLAT

WASHER

2

(2 EA) 1/2-13

NYLOCK NUT &

1/2” FLATWASHER

3

(2 EA) 5/16-18 X

5/8L SQ HEAD SET

SCREWS

4

(1 EA) 1/2-13 X 2-

3/4” BOLT & 1/2

FLAT WASHER

5

(2 EA) 1/4 -20 X 1-1/2” BOLT & 1/4

FLAT WASHER

6

(2 EA) 1/4-20 HEX NUT, INT TOOTH LOCK

WASHER, 1/4 FLAT WASHER

PLACING THE GS4000 MECHANICAL UNIT

Remove the rain seal from the shaft of the GS4000. SAVE IT! The

rain seal will be used later. Next, remove the cover from the GS4000

MECHANICAL UNIT by removing the 1/4 inch diameter bolts on each

side of the Unit and set it aside. It is one of the last items that will be

replaced at the completion of the installation.

The recommended procedure for attaching the GS4000

MECHANICAL UNIT to the concrete pad (for those installations

where the anchor bolts were not previously installed) is first to locate

and drill the hole for the mounting hole nearest to the gate post. Locate

this hole by referring to the diagram in Figure 6. After placing a bolt in

the hole, mark and drill the remaining three holes. This can be

accomplished with the operator in place.

Before inserting the concrete bolts, make sure the GS4000

MECHANICAL UNIT is level. If any corners of the GS4000 are

resting above the pad, flat washers may be inserted under the

MECHANICAL UNIT. Place the flat washers, lock washers and nuts

on the concrete bolts and tighten securely.

For previously placed anchor bolts, the procedure is the same except

that the bolts will already be in place. If 1/2" diameter anchor bolts

were set, the 3/4" mounting holes on the GS4000 MECHANICAL

UNIT will allow some adjustment for desired alignment. Washers can

be used under the GS4000 MECHANICAL UNIT to accurately level

the unit as above.

TO REVIEW: Make sure the correct position of the GS4000

MECHANICAL UNIT from the center line of the gate hinge pivot

point to the center line of the GS4000 is in accordance with the drawing

of Figure 6.

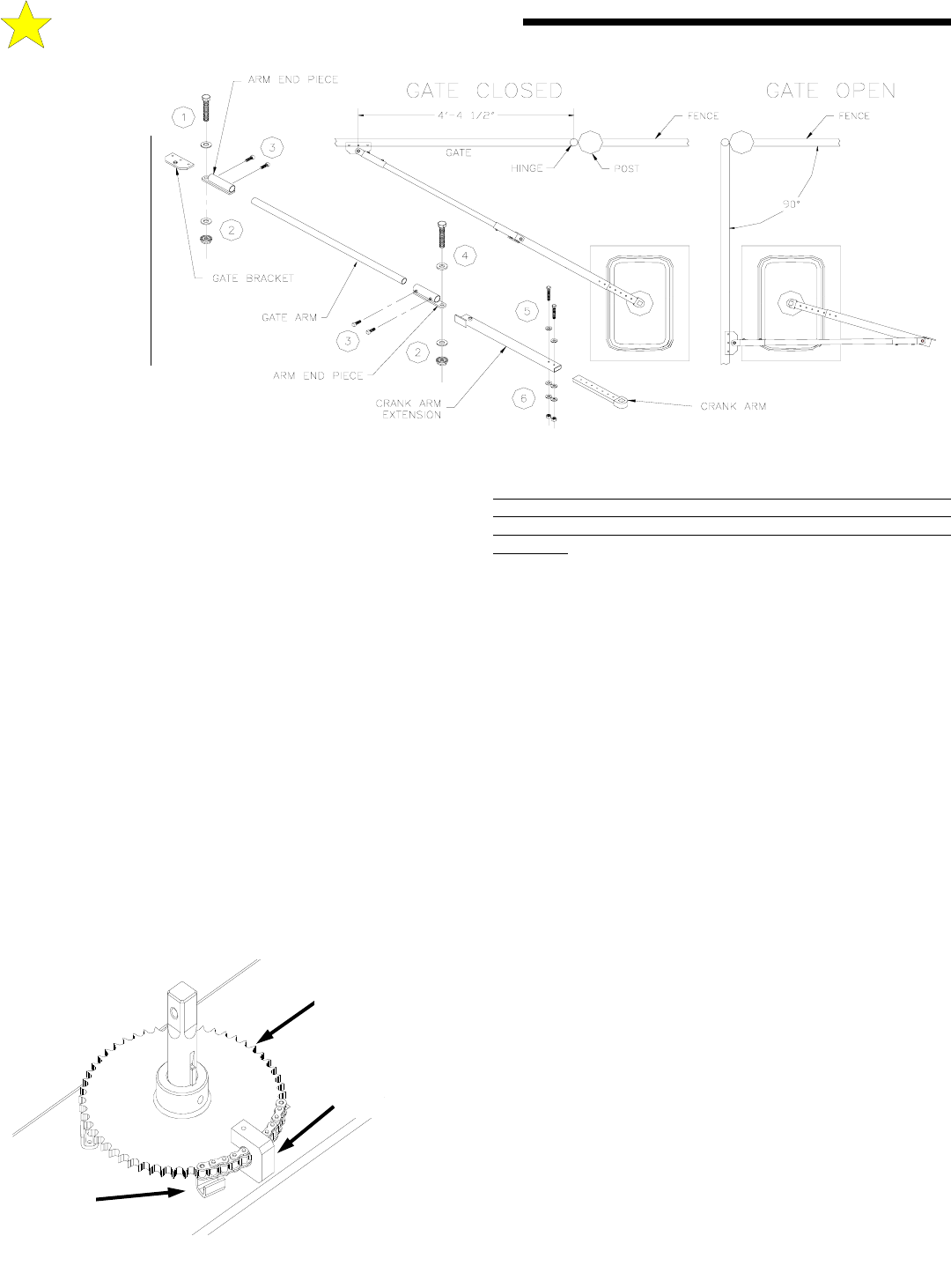

INSTALLING THE GS4000 ARM

Temporarily locate the Gate Bracket on the Gate with C-clamps or

by tack welding. Install the gate bracket to the gate so the gate

arm will be level when connected to the GS4000. See Figure 9 for

positioning of the Gate Bracket.

Loosen the adjustment nut of the Torque Limiter located on the top

of the Gear Box on the GS4000 MECHANICAL UNIT with the 1-

5/8 hex socket. This is done by removing the small set screw on

the large nut and loosening the nut.

For the installation shown in Figure 9, attach the Crank Arm

Extension to the Crank Arm with the (2) 1/4-20 x 1-1/2” long bolts

provided. The overall length of the cranking arm is now 33 5/8”

from the center of the Output Shaft to the center of the pivot at the

“elbow.” Note that the cranking arm is adjustable to (5) possible

settings: 32-1/8”, 30-5/8”, 29-1/8”, 27-5/8” and 26-1/8” long.

Install the Crank Arm and Extension on the GS4000 main shaft and

make sure the Crank Arm swings freely from side to side. Connect

the Gate Arm to the Crank Arm Extension and the Gate Bracket.

With the Gate in the closed position, the "elbow" will be up against

the closed position stop on the Crank Arm Extension. The Gate

should be in the properly closed position. (See Figure 9.)

Loosen the Stop Pall on the large output drive sprocket located on

the output shaft on the GS4000 MECHANICAL UNIT. (See Figure

10.) Move the Gate to the fully open, 90 degree position. The

Arm extension should fold back over the arm as shown in Figure 9.

If it doesn't, some adjustment of the gate bracket or operator

position may be necessary. With the gate in the fully open

position, adjust the stop pall on the sprocket against the stop on the

GS4000 frame and tighten the set screw. Open and close the gate

several times until you are satisfied that the arm position is correct.

Finish welding or bolting the Gate Bracket to the Gate and remove

the C-clamps.

** HARDWARE NOT TO SCALE **

C: INSTALLING THE OPERATOR

Figure 9: Arm Positions

104961

DRIVE

SPROCKET

STOP PALL

Figure 10: Stop Pall

STOP

106318