25

ALL APPROPRIATE SAFETY FEATURES MUST BE

INCORPORATED INTO YOUR GATE SYSTEM.

KEEP GATE IN SIGHT: Never activate the gate unless it is in

sight. Install mounted controls in full view of the gate. Be sure the

gate area is clear before activating the gate, and watch the gate and gate area

as the gate is in motion.

LOCATE MANUAL CONTROLS SAFELY: A manual

control such as a pushbutton or keyswitch must be included in

your gate system design to be used if automatic controls such as radio

controls or loop detectors do not function. Carefully consider the placement

of the manual control: It must be out of reach of the gate so that no one

pushing the button or inserting the card is in the path of the gate or moving

parts; it must also be within sight of the gate so that the operator can watch

the gate and gate area during operation. The recommended minimum

distance between the gate or fence and manual controls accessory is 10

INSTALL SAFETY DEVICES: In residential applications or in

areas where pedestrians may be present, or if your gate closes

automatically, be sure an electric edge(s) and/or a photoelectric sensor(s)

has (have) been installed and is/are operating properly. These features are

intended to detect pedestrian traffic and prevent injury or entrapment.

Loop detectors may be installed to detect vehicular traffic and prevent

vehicular damage.

MAINTAIN THE GATE AND GATE HARDWARE: A

damaged gate or one that cannot be easily opened and closed

manually must be repaired before installing a gate operator. A poorly

operating gate may cause the load sensing device of the operator to fail,

causing a risk of entrapment. Never overtighten the clutch or load sensing

device to compensate for a poorly swinging gate. Correct all mechanical

problems on the gate and gate hardware before installing the gate operator.

Have a qualified service technician make repairs to the gate.

MAINTAIN ALL COMPONENTS OF GATE SYSTEM:

Follow the maintenance instructions included with the gate, the

gate operator, and the safety features and/or accessories that make up your

gate operator system. Have a professional service technician perform any

adjustments or maintenance to the components. Fully test all safety

features monthly. Discontinue the use of faulty safety equipment

immediately, and have the equipment serviced or replaced. by a qualified

service technician. The gate must reverse on contact with a solid, rigid

object or when an object activates the non-contact sensors. After adjusting

the force or limits of travel, retest the gate operator. Failure to adjust and

retest the gate operator properly can increase the risk of injury or death.

KNOW YOUR GATE ARM DISCONNECT FEATURE FOR

MANUAL OPERATION: In the event of a power outage, you

may need to manually operate your gate. The GS4000 is equipped

with a keyed padlock to permit the gate arm to be manually disconnected

from the GS4000 operator. This will allow you to manually push the gate

open or close as needed. Be sure to have the service technician or dealer

installing your gate system give you the key to the padlock and show you

how to use this feature quickly and safely. Keep the key in a safe,

accessible place. Manual operation is to be attempted only when the

operator is not moving the gate under power.

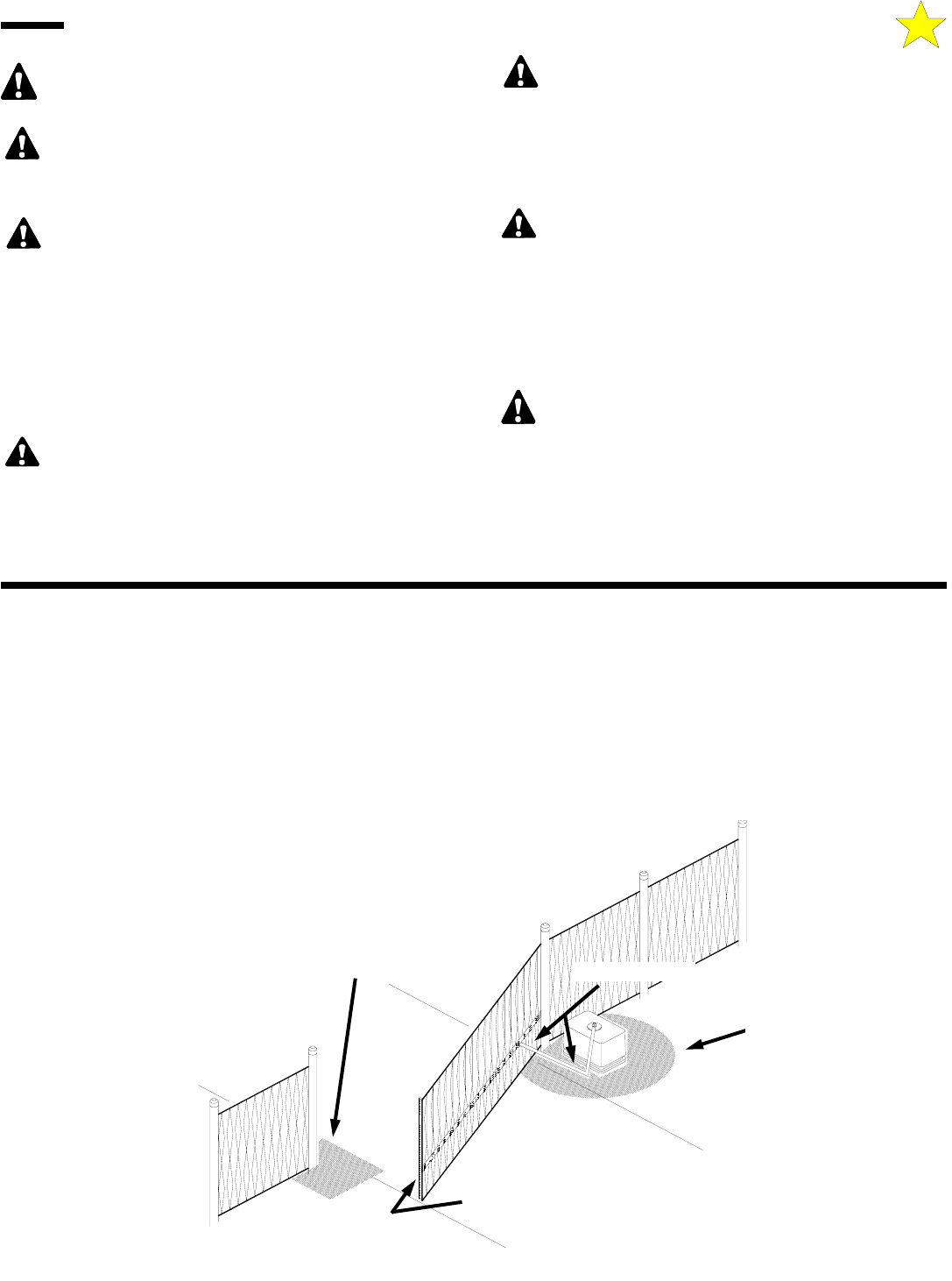

PINCH POINTS

ENTRAPMENT

ZONE

ELECTRIC GATE EDGE

ENTRAPMENT

ZONE

104932

Figure 26: Pinch Points

BASIC OPERATIONAL GUIDE

•If the gate is fully closed an Open Button, Alternate, Radio or Free Exit

input will cause the gate to begin moving in the open direction.

•If the gate is fully open a Close Button, Alternate, or Radio input will

cause the gate to begin moving in the close direction.

•If the gate is moving in a Close direction a Close Non-Contact Sensor,

Close Contact Sensor input or a Close Overload activation will cause

the gate to stop, pause and reverse for approximately 2 inches in the

Open direction.

•If the gate is moving in a Close direction an Open Button, Radio,

Reversing, or Free Exit Loop input will cause the gate to stop, pause

and reverse and run in the Open direction.

•If the gate is moving in a Close direction a Stop Button or Alternate

input will cause the gate to stop. A subsequent Alternate input will

cause the gate to begin moving in the Open direction.

•If the gate is moving in an Open direction an Open Non-Contact

Sensor, Open Contact Sensor input or an Open Overload activation will

cause the gate to stop, pause and reverse for approximately 2 inches in

the Open direction.

•If the gate is moving in an Open direction a Stop or Alternate input will

cause the gate to stop. A subsequent Alternate input will cause the gate

to begin moving in the Close direction.

•Two sequential activations of the Overload detector (Open or Close

direction) before the gate reaches a limit will cause the operator to go

into the alarm mode. To reset the operator remove the obstruction and

either use constant pressure on a control button connected to the OPEN

or CLOSE input and move the gate to a fully open or closed position or

turn off and restore the power to the operator.

F: END USER INSTRUCTIONS GATE OPENER OPERATION & SAFETY GUIDE