SSL/CSL and SSIL/CSIL Series Sight Glass Hopper Loaders

63

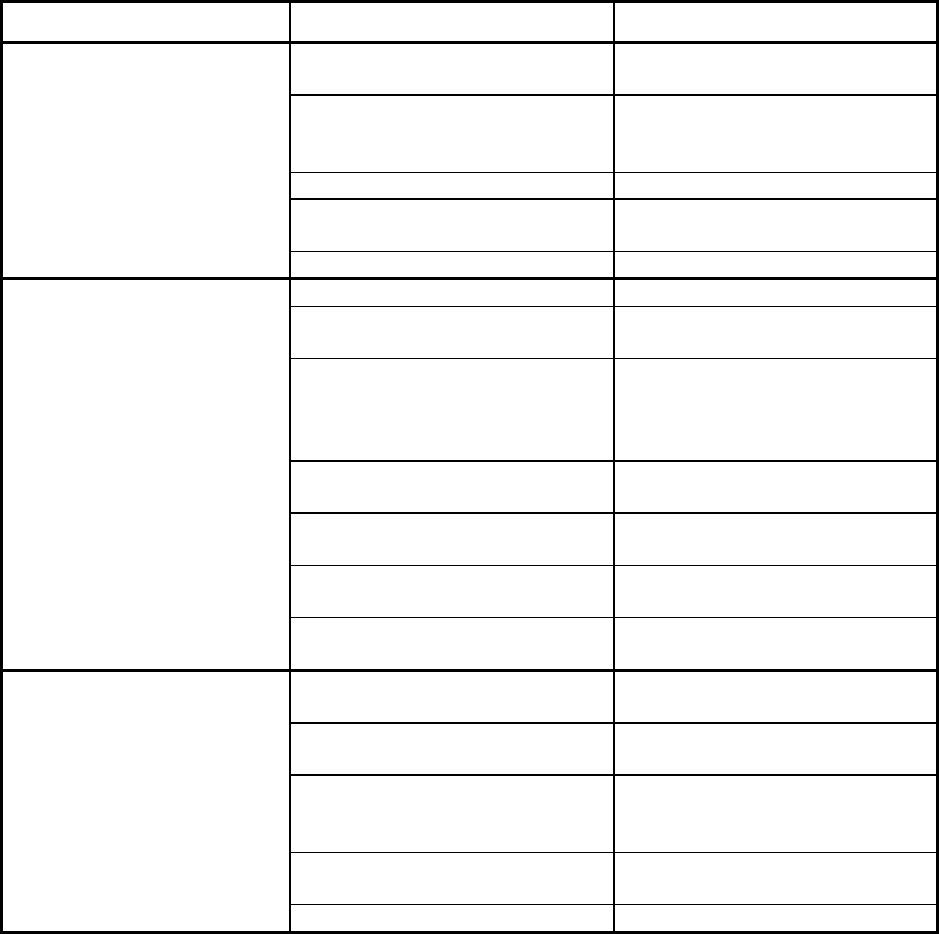

SSL/CSL, SLC and SSIL/CSIL Series Hopper Loaders with Optional Series One Plus Controllers Cont’d.

Problem

Possible cause Solution

The blowback valve is

unplugged.

Plug in the blowback valve

cable.

The number of blowback

pulses on Menu 2 is set to

zero.

Restore Menu 2 to an

appropriate value.

TB1 is loose or disconnected. Secure TB1.

Solenoid valve or its coil has

failed.

Repair or replace as needed.

Control and vacuum motor

are operating normally, but

the blowback cycle isn't

working. The blowback

solenoid makes no sound.

The circuit board has failed. Call the Service Department.

Material supply is low. Fix material supply problem.

Material wand is not properly

positioned in material supply.

Adjust material wand at

material pickup point.

Material wand not adjusted for

the flow characteristics of the

material conveyed.

Adjust material wand to

compensate for flow

characteristics. See Section

3-6 for more information.

Obstructions in supply line.

Clear all obstructions in the

line.

Filter is dirty.

Clean or replace filter as

needed.

Filter is clogged, holding open

the flapper discharge valve.

Replace filter as needed.

Hopper doesn't

fill completely.

Vacuum time is set too low.

Set Menu 1 to an appropriate

value.

Material residue buildup on

proximity sensor.

Clean proximity sensor.

Proximity sensor sensitivity is

set too high.

Reduce sensitivity of sensor.

Material possesses excessive

static properties.

Additional grounding is

necessary. Contact the

Engineering Department.

Control wiring connections on

circuit board are loose.

Secure connections on circuit

board.

Proximity switch trips

before tank is full.

Proximity sensor wire is cut. Replace proximity sensor.