SSL/CSL and SSIL/CSIL Series Sight Glass Hopper Loaders

62

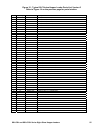

SSL/CSL, SLC, and SSIL/CSIL Series Hopper Loaders with Optional Series One Plus Controllers

Problem

Possible cause Solution

No power to control box.

Plug in power cord; check

main disconnect.

Power switch is off. Turn ON control box.

External fuse 1FU is blown Replace fuse 1FU.

Internal fuse FU2 is blown Replace fuse FU2.

TB1 is disconnected or loose. Reconnect or tighten TB1.

Ribbon cable to the display is

loose.

Tighten ribbon cable; check

both ends.

Loose wiring in the control. Check and tighten wiring.

No LED display.

Circuit board has failed. Replace circuit board.

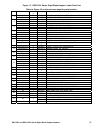

Bin full sensor reed switch is

tripped.

Wait for machine bin material

level to drop, then manually re-

start the hopper loader.

Misaligned bin full sensor reed

switch magnet.

Realign magnet.

Bin full sensor reed switch has

failed.

Replace.

Bin full sensor reed switch

wiring is loose/disconnected.

Repair the wiring fault.

TB2 is loose or disconnected. Re-connect or tighten.

Ribbon cable to the display is

loose or disconnected.

Re-connect or tighten.

AEC

is displayed at power-

up, but vacuum motor

doesn’t start when the

S

START/STOP

START/STOP/SELECT/

SET

key is pressed. The

screen continues to

display

AEC

.

Defective keypad. Call the Service Department.

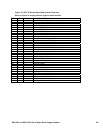

Vacuum motor unplugged from

the control.

Plug in the vacuum motor.

Vacuum time is set to zero (0)

on Menu

1

.

Reset Menu

1

to an

appropriate time.

The vacuum motor has failed.

Repair or replace vacuum

motor as needed.

Solid-state relay has failed. Replace.

Control and display appear

to operate normally, but

the vacuum motor never

starts.

The circuit board has failed. Call the Service Department.

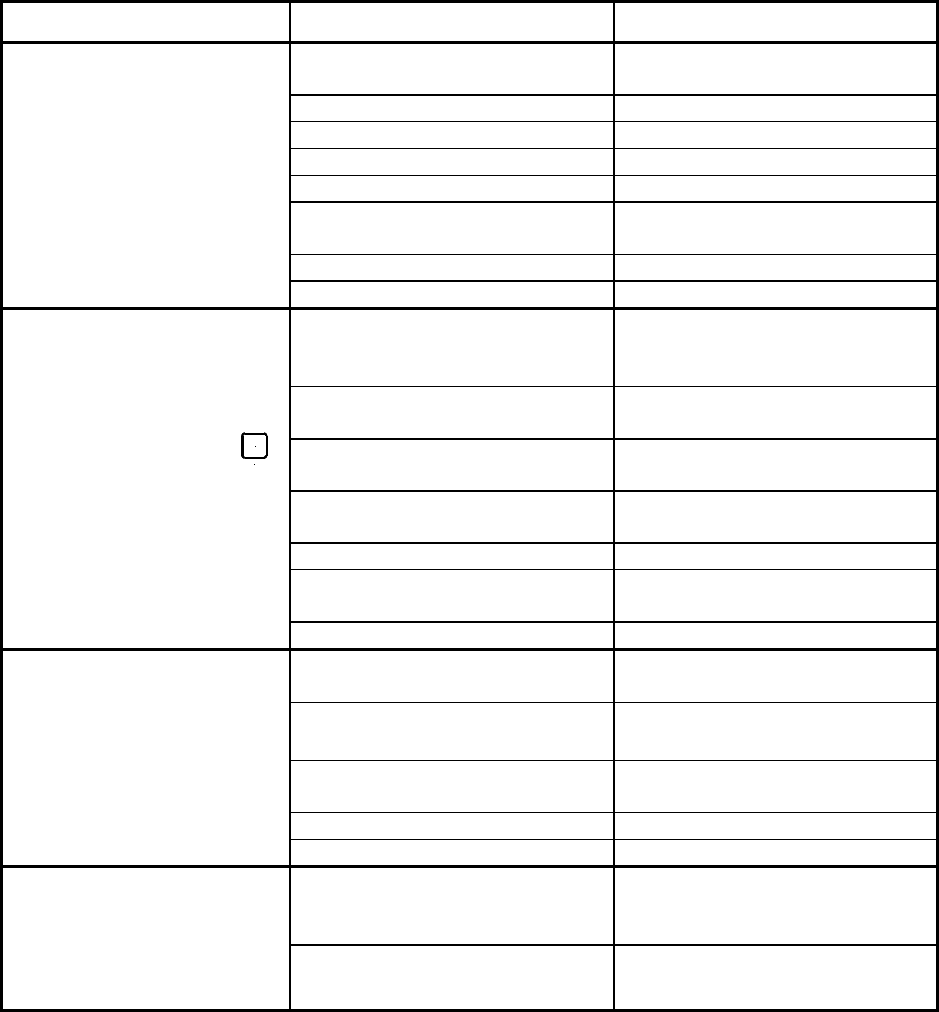

No or insufficient compressed

air.

Fix compressed air supply.

Connect to 80 psi (551.6 kPa/

5.5 bars) supply.

Control and vacuum motor

are operating normally, but

the blowback cycle isn't

working. The blowback

solenoid clicks.

Restricted compressed air line. Find and fix restriction.