54

Appendix C: Disc Dosing Factors And Equipment Drawings And Parts

Numbers

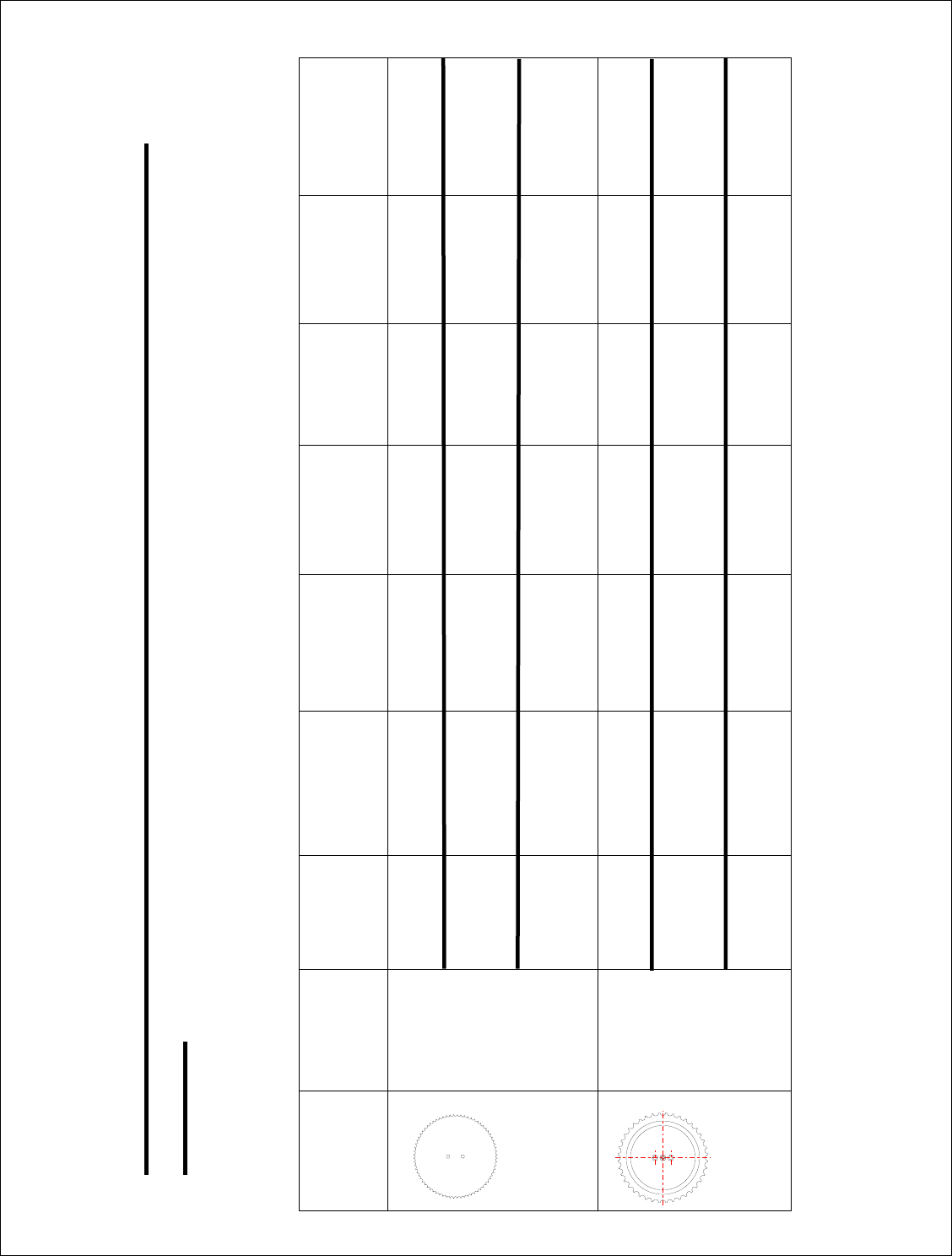

Disc Dosing Factor Table 1: Disc Guide

Disc

Disc

Nomenclature

Used in the

Controller

Minimum/

Maximum Disc

Revolution

Weight Per Disc

Revolution

(Bulk Density

35lb/cuft)

Min. Throughput

with 100%

Continuous

Running (Bulk

Density 35lb/cuft)

Max.Throughput

with 100%

Continuous

Running (Bulk

Density 35lb/cuft)

Weight Per Disc

Revolution

(Bulk Density

44lb/cuft)

Min. Throughput

with 100%

Continuous

Running Bulk

Density 44lb/cuft)

Max.Throughput

with 100%

Continuous

Running (Bulk

Density 44lb/cuft)

DD30-030672

Default

Calibration #

1.50 g/rev

P030672

# of Holes

Diameter

Disc Thickness

0.2 Rev./min

6.4Rev./min

(6.4 RPM)

0.5 Rev./min

11.5 Rev./min

(11.5 RPM)

1.0 Rev./min

35.5 Rev./min

(35.5 RPM)

1.53 g/Rev.

0.02 g/Hole

0.04 lb/hr

0.02 kg/hr

0.10 lb/hr

0.045 kg/hr

0.19 lb/hr

0.09 kg/hr

1.30 lb/hr

0.59 kg/hr

2.32 lb/hr

1.05 kg/hr

7.16 lb/hr

3.25 kg/hr

1.95 g/Rev.

0.027 g/Hole

0.04 lb/hr

0.02 kg/h

0.12 lb/hr

0.05 kg/hr

0.26 lb/hr

0.12 kg/hr

1.65 lb/hr

0.75 kg/h

2.89 lb/hr

1.31 kg/hr

9.00 lb/hr

4.10 kg/hr

D30-051040

Default

Calibration #

4.00 g/rev

051040

# of Holes

Diameter

Disc Thickness

0.2 Rev./min

6.4 Rev./min

(6.4 RPM)

0.5 Rev./min

11.5 Rev./min

(11.5 RPM)

1.0 Rev./min

35.5 Rev./min

(35.5 RPM)

4.24 g/Rev.

0.11 g/Hole

0.11 lb/hr

0.05 kg/hr

0.27 lb/hr

0.12 kg/hr

0.55 lb/hr

0.25 kg/hr

3.59 lb/hr

1.63 kg/hr

6.33 lb/hr

2.87 kg/hr

19.80 lb/hr

9.00 kg/hr

5.39g/Rev.

0.13 g/Hole

0.15 lb/hr

0.07kg/h

0.35 lb/hr

0.15 kg/hr

0.70 lb/hr

0.32 kg/hr

4.56 lb/hr

2.07 kg/h

8.00 lb/hr

3.62 kg/hr

25.30 lb/hr

11.50 kg/hr

Note 1: This guide is to be used for general disc selection for Digital Dosing unit applications. All rates shown are continuous throughput and are

based on free-flowing materials. Consult factory for regrind, powder and all hard to flow materials.

Note 2: Maximum feeder disc revolutions in one screw recovery period (injection mode) is 9.5 revolutions. Use proper disc sizing for injection mode

applications to ensure proper dispense of material during the recovery cycle. Maximum dispense during a recovery cycle should not exceed 9.5

revolutions of the metering disc.