29

p/n GH 19502091

SERVICE

Cleaning and oiling the cutters

DANGER

Mowing bar cleaning and oiling are very dangerous

operations. Always comply with the following

instructions:

• Switch off the tractor, remove the starter key and disengage

the pto;

• Brake the tractor and make sure it is unable to move;

• Lift the implement by means of the lift links in a flat place

where it cannot slip;

• Operate the mowing bar, checking that there are no

persons or animals in the vicinity;

• Wash the mowing bar with a jet of pressurized water,

standing at least 5 feet away from the implement;

• Check the condition of the cutters;

• When the mowing bar is dry, oil the cutters with very

viscous oil;

• Operate the mowing bar for a few seconds, checking that

there are no persons or animals in the vicinity;

• Switch off the tractor, remove the starter key and disengage

the pto;

• Fit the guards over the cutters and outer skid (C Fig. 49)

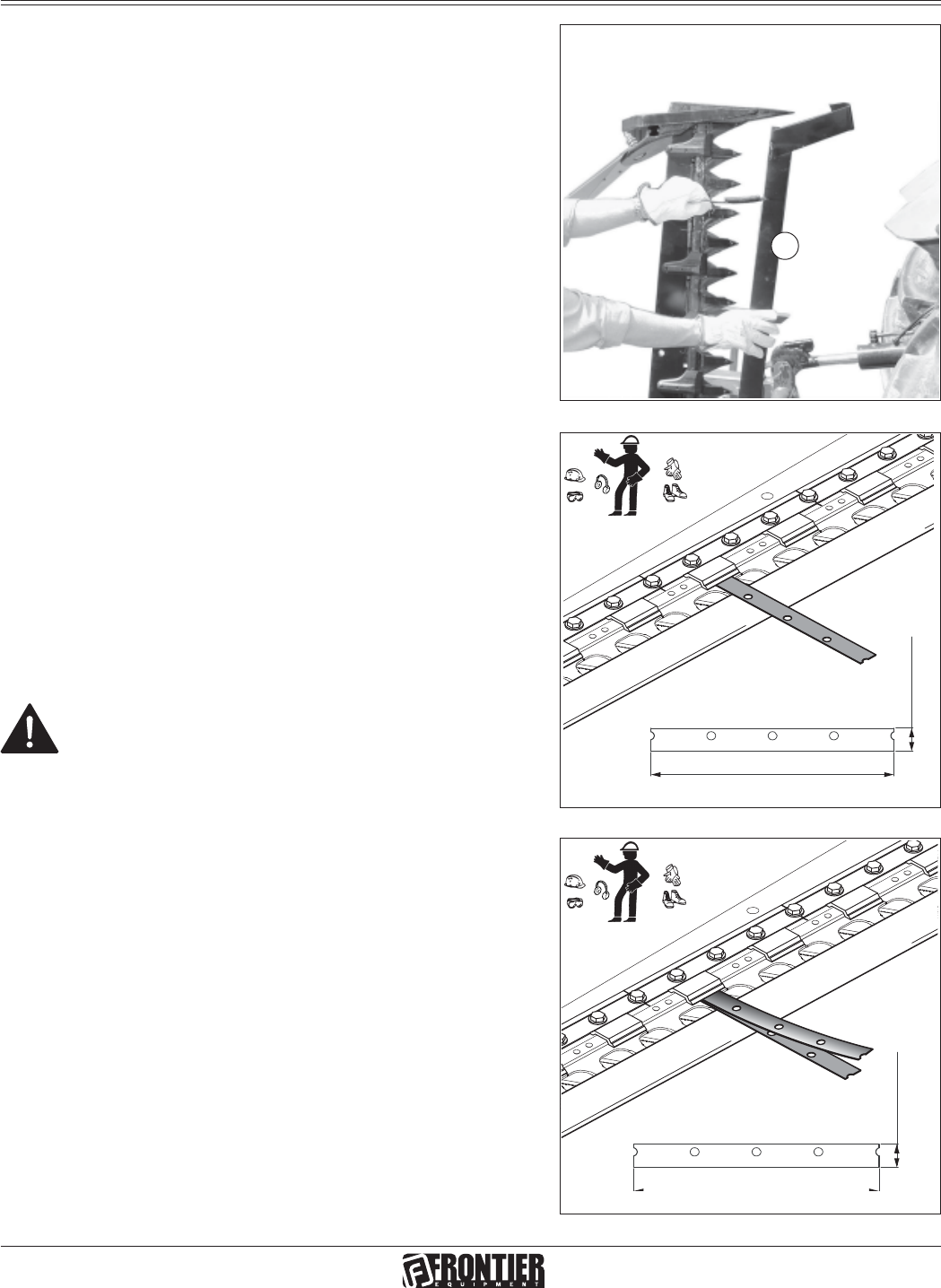

Checking the clearance tolerance

Fig. 49

C

ATTENTION

It is absolutely essential to disengage the tractor

pto, lower the mowing machine, switch off the

tractor, ensure that this is at a complete standstill

and remove the key before servicing, adjusting

the implement for work. All assembly operations

must be carried out on a work bench.

Every 50 hours of operation, the clearance between the tooth

and upper blade guide must be checked. Too much

clearance allows material to enter the cutting blade, leading

to the possible breakage of the various parts of the cutting

blade, as well as compromising cutting quality. Too little

clearance creates excessive sliding friction on the blade as

it slides, leading to the possible breaking of the tooth holding

bar, the blade head or parts of the hinge. The check is to run

between the tooth and the upper blade guide. The optimal

clearance is determined by the passing of a shim (Fig. 50).

If a shim cannot pass between the tooth and upper blade

guide, a shim must be added (Fig. 53). If, on the other hand,

two coupled shim can pass (Fig. 51), a shim must be removed

in order to restore optimal clearance conditions.

Fig. 51

Fig. 50

1.18 inches

11.9 inches

thicknes ~0.04 inches (1mm)

1.18 inches

11.9 inches

thicknes ~0.04 inches (1mm)

ONE SHIM (GH 13011510)

TWO SHIMS (GH 13011510)