SERVICE

28

p/n GH 19502091

WARNING: • Firmly block sickle bar on horizontal surface.

• Always keep oils and greases well away from children’s reach.

• Always thoroughly read the warnings and precautions indicated on the

containers. Avoid contact with the skin.

• Always thoroughly and fully wash after use. The utilized oils should be

treated in compliance with the current anti-pollution laws.

Routine maintenance

• During the first working hours, check that the screws are

tight (Fig. 56).

Every 8 work hours

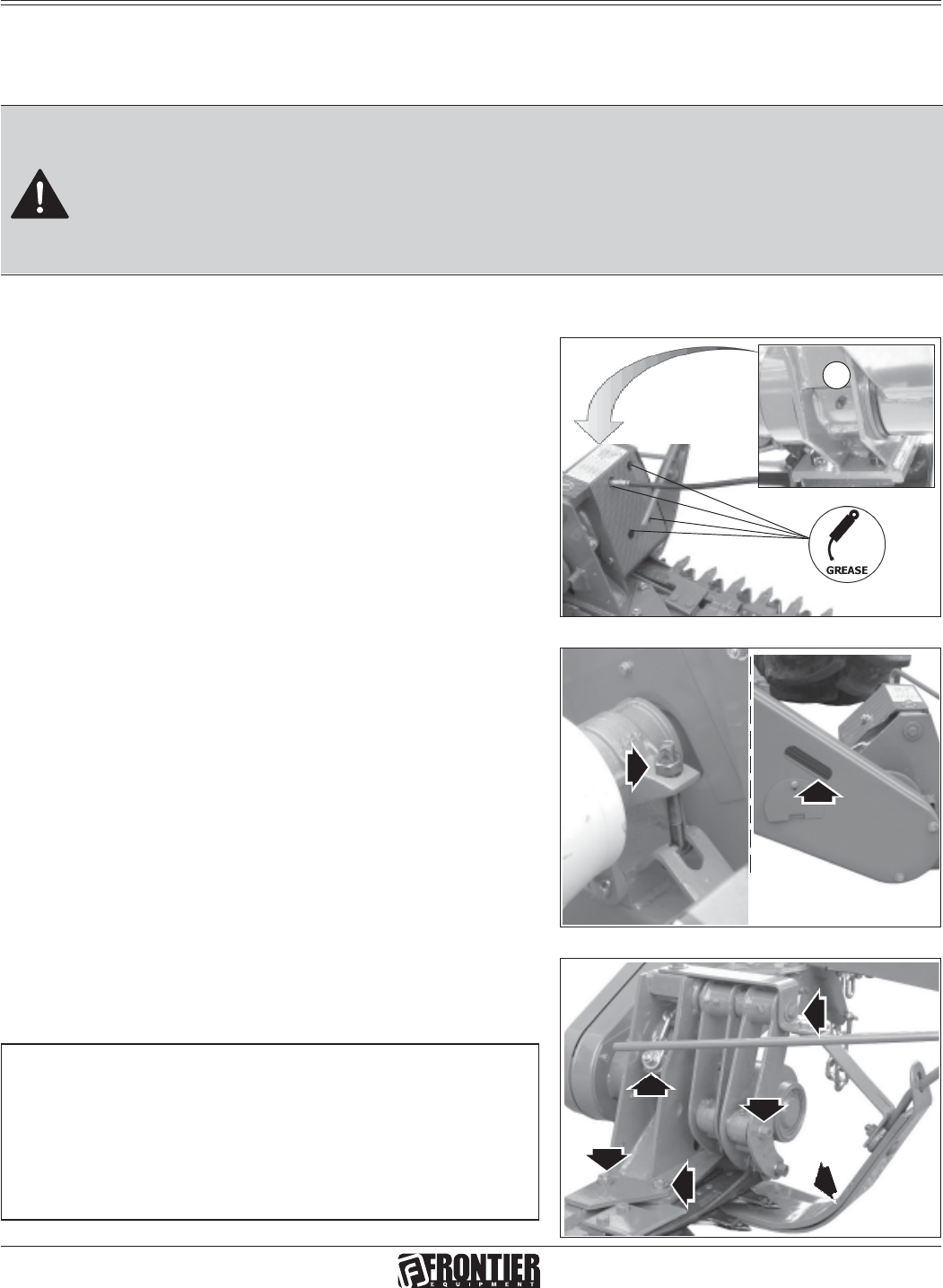

• Grease points (A and B, Fig. 46).

• Grease the PTO shaft and its telescoping parts.

• Adjust belt tension periodically by adjusting nut (A, Fig.

47). Check tension via the viewing panel on the belt

guard. Belt slack must not exceed 1 inch. It is essential

to close the inspection hatch with the relative lid after the

belts have been examined.

Every 50 work hours

• Check the tightness of the connecting rod bolts regularly

(Fig. 48).

• Checking the clearance tolerance

Periodically (6 months)

• Grease point (A and B, Fig. 46).

After each mowing job

• Clean and oil the mowing bar blades according to

the instructions in the chapter entitled: "Cleaning

and oiling the cutters".

A

A

Lubricants

• It is advisable to use SAE 85W/140 OIL or equivalent

for the reduction unit (or gear box) and side

transmission.

• It is advisable to use GR MU EP 2 GREASE or

equivalent for all greasing points.

Fig. 46

Fig. 47

Fig. 48

B

Lubrication