9

Assembly

Tools required for assembly:

crane with hoist; or forklift

9/16", 7/16" and 1/2" wrenches

level

1. Remove all wood crating from around the

shaper.

2. Remove the bolts securing the machine to

the skid.

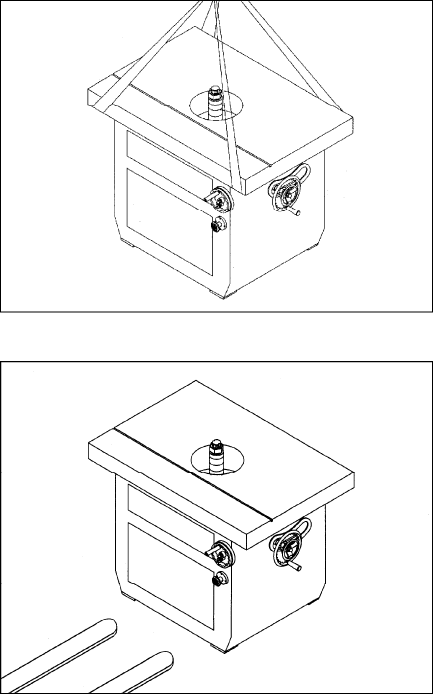

3. The shaper can be lifted by a crane with

hoist (Figure 1), or by a forklift (Figure 2),

either of which should be capable of lifting

one ton. Remove the skid from under the

shaper.

4. The shaper should be placed on a solid,

level foundation, preferably a concrete floor.

With the machine in position, check table

surface left to right and front to back with a

machinist's level. If necessary, place metal

shims under the corners of the machine to

ensure it is level.

5. Secure the machine to the floor with good

quality lag screws through the holes in the

bottom of the cabinet.

6. Exposed metal parts such as the table top

have been given a protective coating at the

factory. This should be removed with a soft

cloth and solvent (such as mineral spirits).

Do not use an abrasive pad.

Interchangeable Spindle Installation

One of the features of this machine is that it will

accept interchangeable spindles with a drawbar

or without a draw bar. Router bits can also be

used on this shaper.

Interchangeable Spindle with

Drawbar

1. Disconnect the machine from the power

source and remove the table inserts (NOTE:

Removing the tilting insert is not necessary).

2. Raise the spindle shaft all the way up.

3. Thoroughly clean the taper of the

interchangeable spindle and the internal

taper of the shaft with a soft cloth moistened

with kerosene or mineral spirits (do not use

gasoline or lacquer thinner).

Figure 1

Figure 2