20

Maintenance

Disconnect machine from

power source before doing any maintenance.

Periodically clean the inside of the machine of

shavings and dust. This will increase machine

performance and extend its life.

Clean the spindle with compressed air.

Do not get oil on the pulleys and belts. If they

are dirty, use paper or a soft rag to clean and

dry them.

Never place the v-belt under excessive strain, as

this can overload the motor and damage the

bearings, spindle or belt.

If the power cord is worn, cut, or damaged in

any way, have it replaced immediately.

The table surface must be kept clean and free of

rust for best results. Some users prefer a paste

wax coating. Another option is talcum powder

applied with a blackboard eraser rubbed in

vigorously once a week; this will fill casting

pores and form a moisture barrier. This method

provides a table top that is slick and allows rust

rings to be easily wiped from the surface.

Important also is the fact that talcum powder will

not stain wood or mar finishes as wax pickup

does.

Lubrication

Apply a drop of light machine oil occasionally on

the ledge and wall of the table opening to

facilitate the changing of table inserts.

The bearings in the motor are sealed for life and

do not require lubrication.

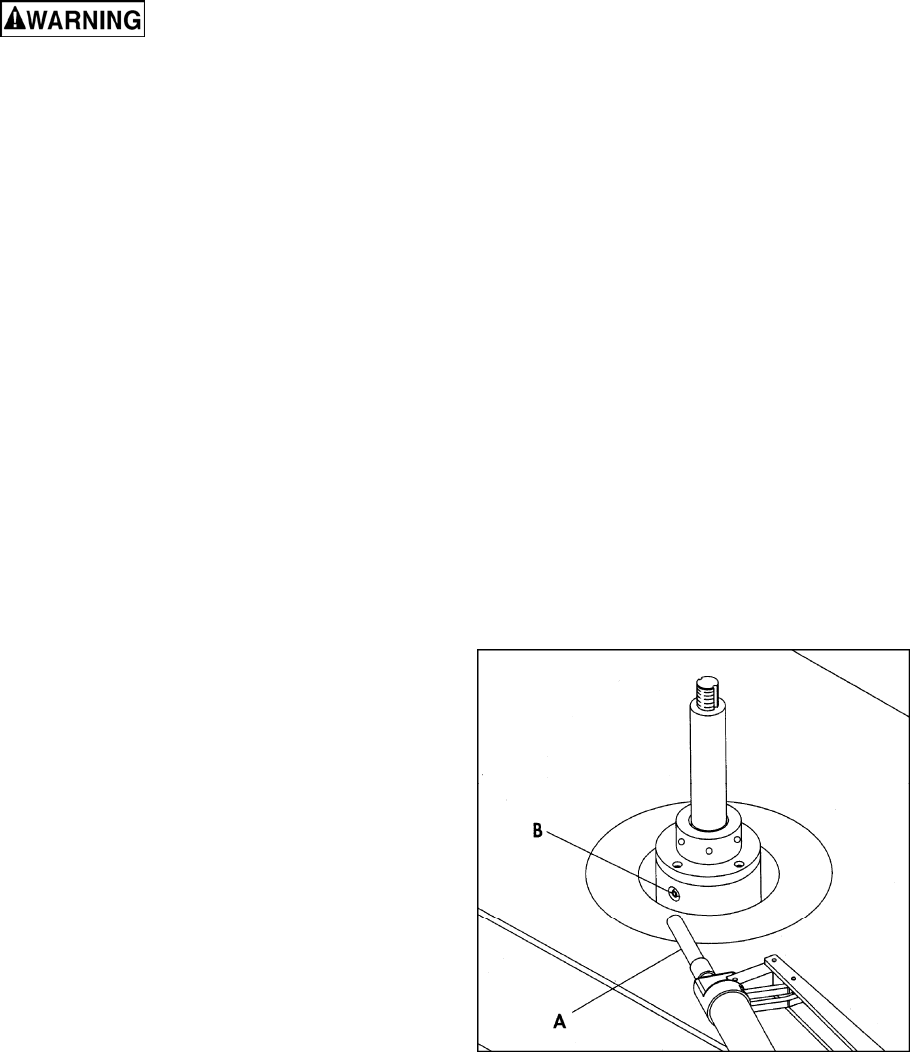

The spindle bearing should be lubricated every

200 hours of use by using the supplied grease

gun (A, Figure 35). Two grease fittings, one of

which (B, Figure 35) is shown, are supplied on

the spindle housing for this purpose. The other

grease fitting is directly opposite. Before

lubricating, clean grease fittings thoroughly and

then lubricate the spindle bearings with two

pumps of a good quality, non-hardening grease.

Figure 35