14

from the machine.

Adjustments

Speed Change

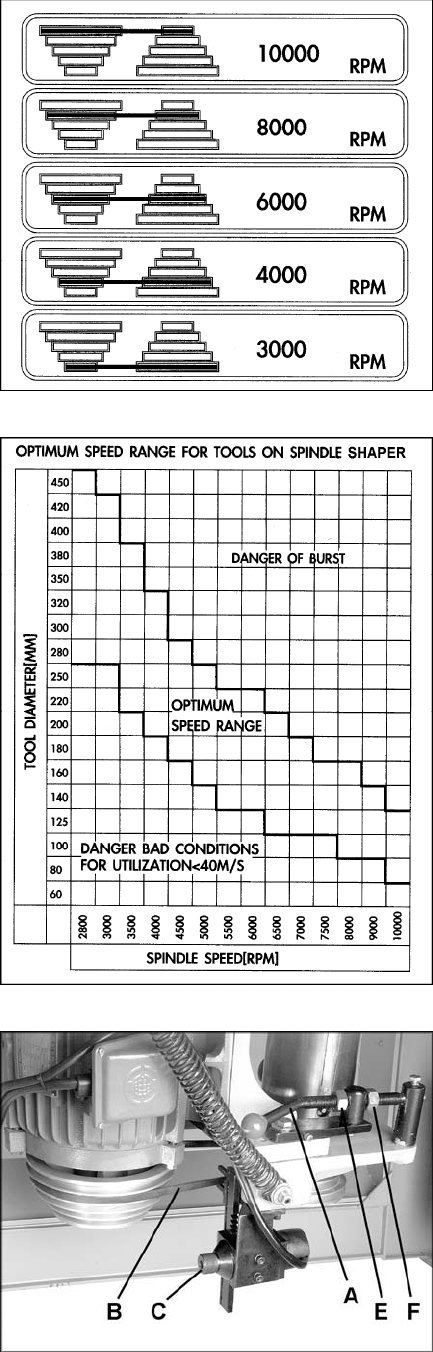

Your machine is supplied with a 5-step motor

pulley and a 5-step spindle pulley that provide

spindle speeds of 3000, 4000, 6000, 8000 and

10,000 RPM.

A speed chart, shown in Figure 18, is located on

the inside of the front cabinet door for easy

reference of the belt position on the pulleys for

the five speeds available.

Check machine speed setting before operating.

Make sure cutter meets or exceeds speed rating

of tool. Figure 19 shows a chart for finding

optimum speed range in relation to the cutter

size. A similar chart can be seen on the front of

the shaper, with indicator lights showing the

current speed of rotation.

The cutting speed should always exceed 40

meters-per-second to lessen risk of kickback but

should not exceed 70 m/s to lessen the risk of

tool damage.

To change the speed and adjust the proper belt

tension, proceed as follows:

1. Disconnect machine from power source.

2. Open front cabinet door and move belt

tension lever (A, Figure 20) to the right to

loosen belt tension.

3. Move the belt (B, Figure 20) to the desired

position on the pulleys, while at the same

time rotate the knob (C, Figure 20) on the

speed indicator so that the belt will remain

positioned in the cut-out in the speed bar.

4. When the belt is positioned properly, move

the tension lever (A, Figure 20) to the left.

NOTE: During the first use after speed

adjustment, the belt will settle and produce a

slight decrease in tension. To obtain best

tension, turn the two nuts (E & F - Figure 20).

Proper belt tension is achieved when the belt

midway between the pulleys can be deflected

using moderate finger pressure.

Figure 18

Figure 19

Figure 20