16

Fence Adjustment

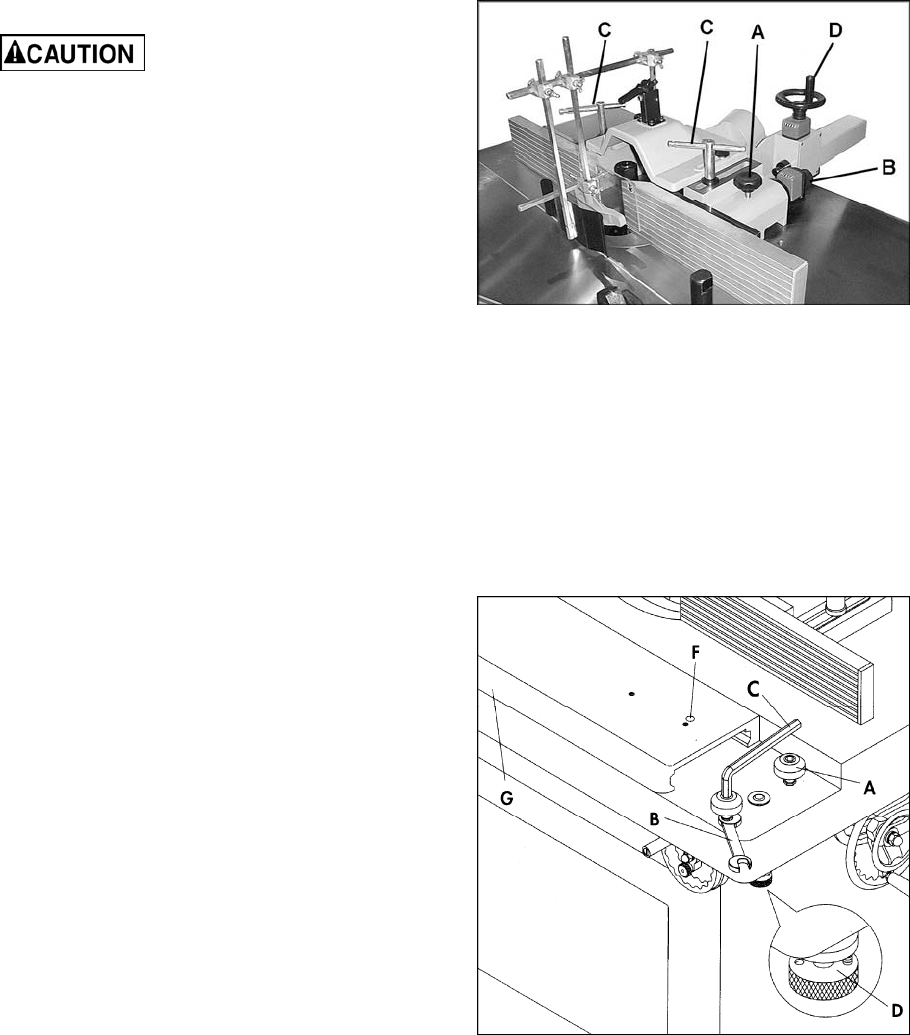

1. To laterally adjust the aluminum fence

plates, loosen the two fence locking levers

(refer to C, Figure 8), slide the fence plates

to the required positions and tighten locking

levers.

The aluminum fence plates

should be adjusted inward so that the

opening at the spindle is just enough to clear

the cutter.

2. The right fence plate (infeed) can be moved

independently, in or out, depending on the

type of shaping operation that is being

performed. To move the right fence plate in

or out, loosen the locking knob (A, Figure

23) and turn the adjusting knob (B, Figure

23). Precise movements are possible by

using the dial indicator beneath the knob.

When finished, re-tighten locking knob (A,

Figure 23).

3. The entire fence assembly can be rapidly

positioned on the table by slightly loosening

both locking handles (C, Figure 23) and

moving the fence assembly to desired

position by rotating the handwheel (D,

Figure 23). Use the dial indicator for more

precise measurement. Re-tighten the

handles (C, Figure 23) when finished.

Sliding Table Adjustment

There are six adjustable eccentric rollers (A,

Figure 24) on the sliding table. Wherever the

sliding table is unstable or not traveling in line,

adjust the sliding table as follows:

1. Loosen the roller (A, Figure 24) with a hex

wrench (C, FIgure 24).

2. Use open end wrench (B, Figure 24) to

rotate the rollers as needed.

3. Lock the setting of the roller by using the

hex wrench (C, Figure 24).

To operate the sliding table (F, Figure 24) pull

down on the knurled knob (D, Figure 24) and

rotate it 180 degrees until the opposite hole

engages the pin. The sliding table can then be

moved back and forth.

To lock the sliding table in centered position,

move the sliding table flush with the main table.

Pull down on the knurled knob (D, Figure 24)

and rotate it 180 degrees until it engages the

pin.

Figure 23

Figure 24