19

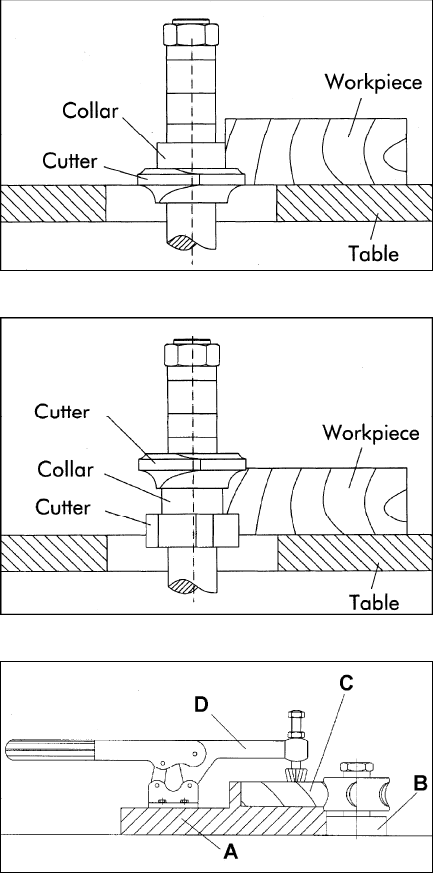

2. When the collar is used above the cutter, as

shown in Figure 32, the cut cannot be seen,

but this method offers an advantage in that

the cut is not affected by slight variations in

the thickness of the stock. Also, accidental

lifting of the workpiece will not gouge the

workpiece; simply repeat the operation to

correct the mistake.

3. Using the collar between two cutters has the

advantages and disadvantages of the first

two procedures, and is frequently used

where both edges of the work are to be

molded. See Figure 33.

NOTE: It is advisable to place the cutter as low

as possible on the spindle to reduce spindle

deflection and ensure the best possible finish.

Also make sure that the contacting surfaces of

the cutter are smooth, sharp, clean and without

dents.

Copying (Machining with a Jig)

When using the same procedure on multiple

workpieces, a jig or template can be made to

facilitate the operation.

1. Prepare the jig (A, Figure 34) to accomodate

your original workpiece.

2. Place the jig (A, Figure 34) against the table

ring guide shoulder (B, Figure 34).

3. Fasten the new workpiece (C, Figure 34) on

the jig (A, Figure 34) with the clamp (D,

Figure 34) and push the assembly past the

cutter.

Feeding Stock

Power feeders are available and can be ordered

by calling our customer service number. These

units mount to the shaper table and will help

ensure smooth, consistent feed of material, as

well as keep hands safely away from the

cutterhead.

Stock No.

1790800K 3-Wheel Feeder, 1HP, 3Ph, 230V

1790810K 3-Wheel Feeder, 1HP, 3Ph, 460V

1790811K 4-Wheel Feeder, 1HP, 3Ph, 230V

Figure 32

Figure 33

Figure 34